Connecting structure of integrated panel and fluid device

A technology of integrated panel and connection structure, applied in the direction of sealing surface connection, passing components, engine components, etc., can solve the problems of reduced bolt fastening force, leakage of connection parts, unfavorable connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

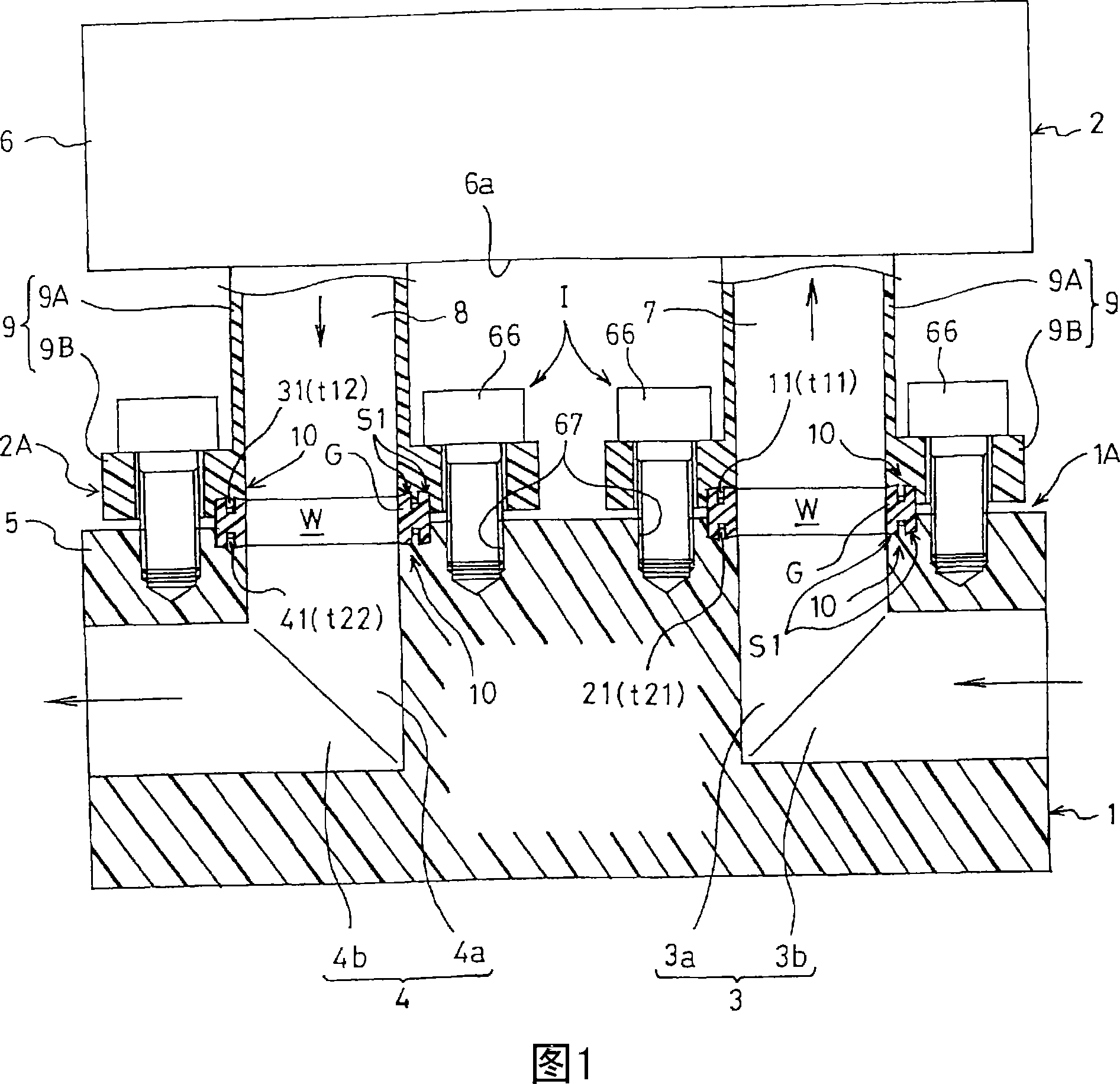

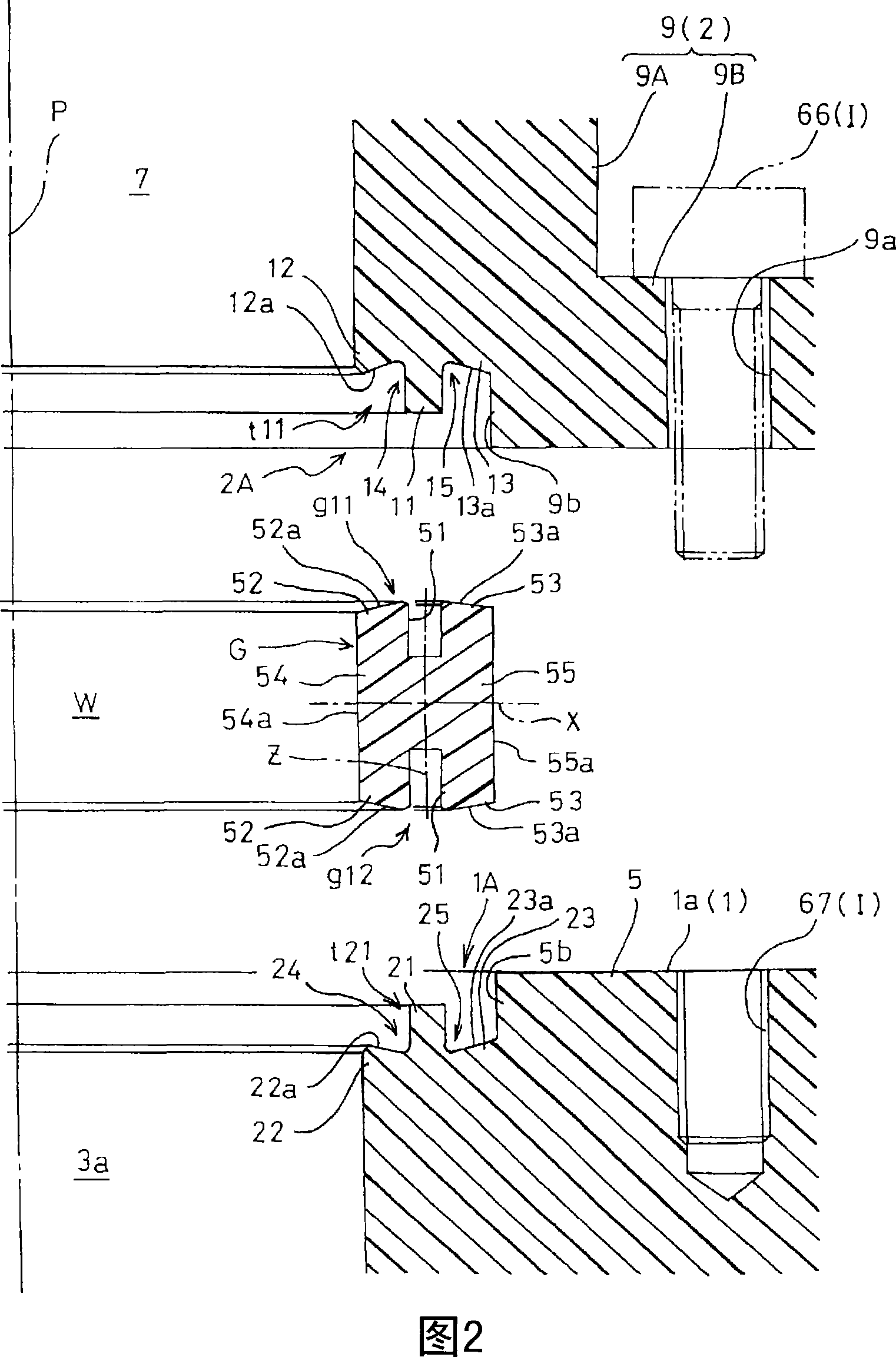

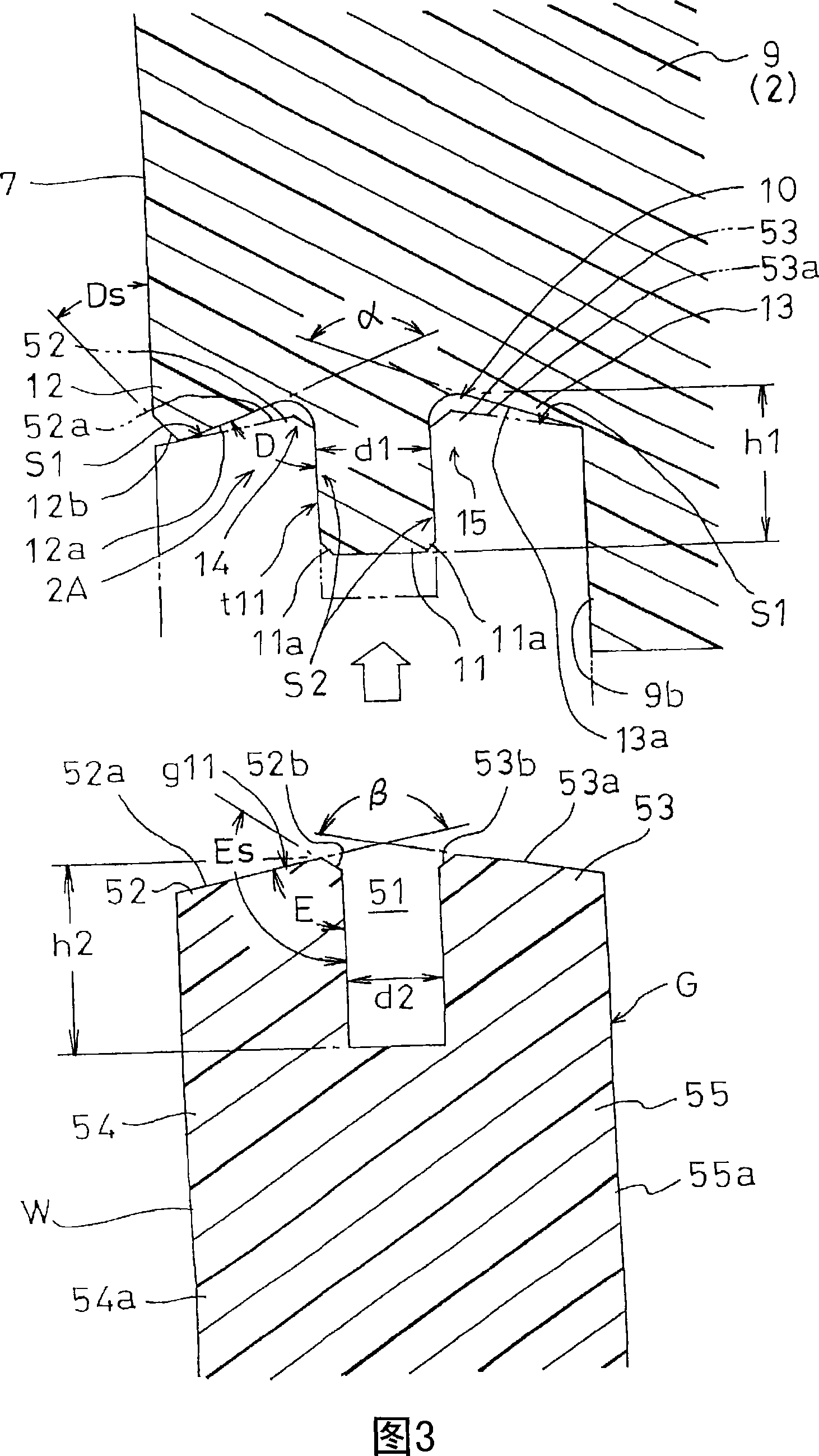

[0119] FIG. 1 and FIG. 2 show the connection structure of the integrated panel and the fluid device according to the first embodiment. The connection structure between the integrated panel and the fluid device is a single-channel type structure, which consists of an integrated panel 1 with a pair of circular tubular fluid flow channels 3 and 4 formed inside and an upper surface 1a of the integrated panel 1 separated by a The valve (opening and closing valve, shut-off valve, etc.) 2 mounted on the annular gasket G is constituted, and shares the longitudinal axis P. That is, a pair of connection structures for the supply and row use the same structure as each other.

[0120] As shown in FIGS. 1 and 2 , the integrated panel 1 has a structure in which a pair of cylindrical supply-side fluid flow passages 3 and 4 are formed inside a panel material (or block material) 5 made of a fluororesin such as PFA or PTFE. The supply-side fluid flow channels 3 and 4 are constituted by vertica...

Embodiment 2

[0143] FIG. 4 shows the connection structure of the integrated panel and the fluid device of the second embodiment. This is a structure in which the integrated panel 1 is connected to the filter 2, which is an example of a fluid device, and the connection structure itself is the same as that of Embodiment 1 shown in FIGS. 1 to 3 . Therefore, the same reference numerals are attached to the same positions, and the description thereof will be omitted.

[0144] The filter 2 is composed of a main body case 2K, a lower case 2B, and a filter body 2C, and the lower case 2B is formed with a fluid flow passage 7 on the supply side and a fluid flow passage 8 on the discharge side, and the state of having these fluid flow passages 7 and 8 is formed. A pair of mounting flanges 9 and 9 are formed by protruding lower laterally. These mounting flanges 9 , 9 and the integrated panel 1 are connected via a gasket G in communication.

Embodiment 3

[0146] As shown in FIG. 5 , the connection structure between the integrated panel and the fluid device in Embodiment 3 is an example of the integrated panel 1 and the fluid device, that is, the connection structure of the regulator 2 . The regulator 2 includes a casing 2C composed of an upper case, a middle case, and a lower case. Between the upper case and the middle case, a bellows tube (not shown) whose peripheral parts are clamped is accommodated. A valve body (not shown) whose peripheral portion is clamped is accommodated between the case and the lower case, and a return spring is accommodated in the lower case.

[0147] The housing 2C is integrally provided with a pair of mounting flanges 9 and 9 protruding in the lateral direction, and the regulator 2 is connected to the integrated panel 1 via the gasket G by these mounting flanges 9 and 9. Surface 1a. The connection structure between the mounting flange 9 and the upper surface 1a of the integrated panel 1 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com