Gas adsorbing device, vacuum heat insulator making use of gas adsorbing device and process for producing vacuum heat insulator

A gas adsorption, vacuum insulation technology, applied in heat exchange equipment, pipeline protection through thermal insulation, thermal insulation, etc., can solve problems such as difficulty in operation, and achieve the effect of improving yield, maintaining vacuum for a long time, and small deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

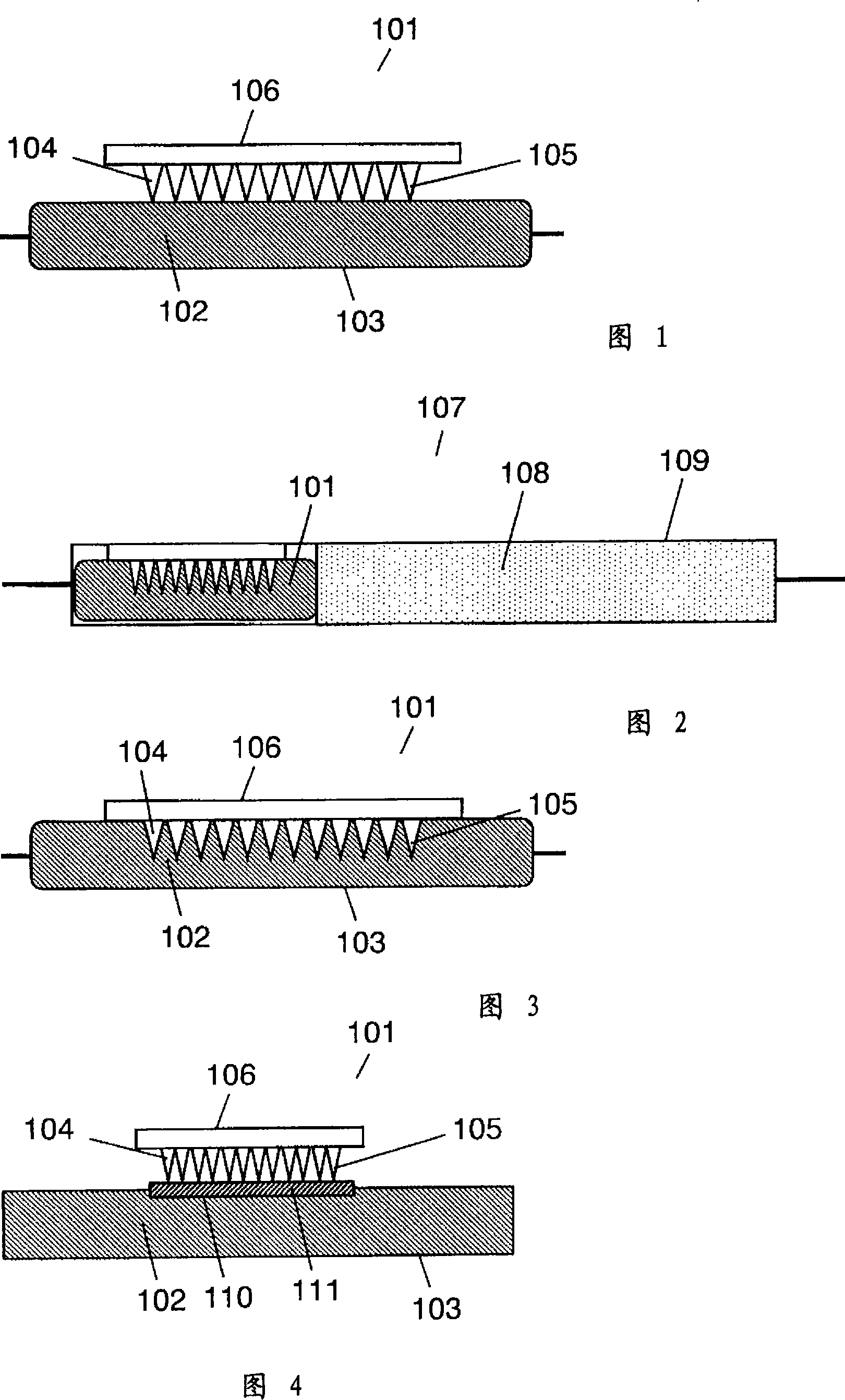

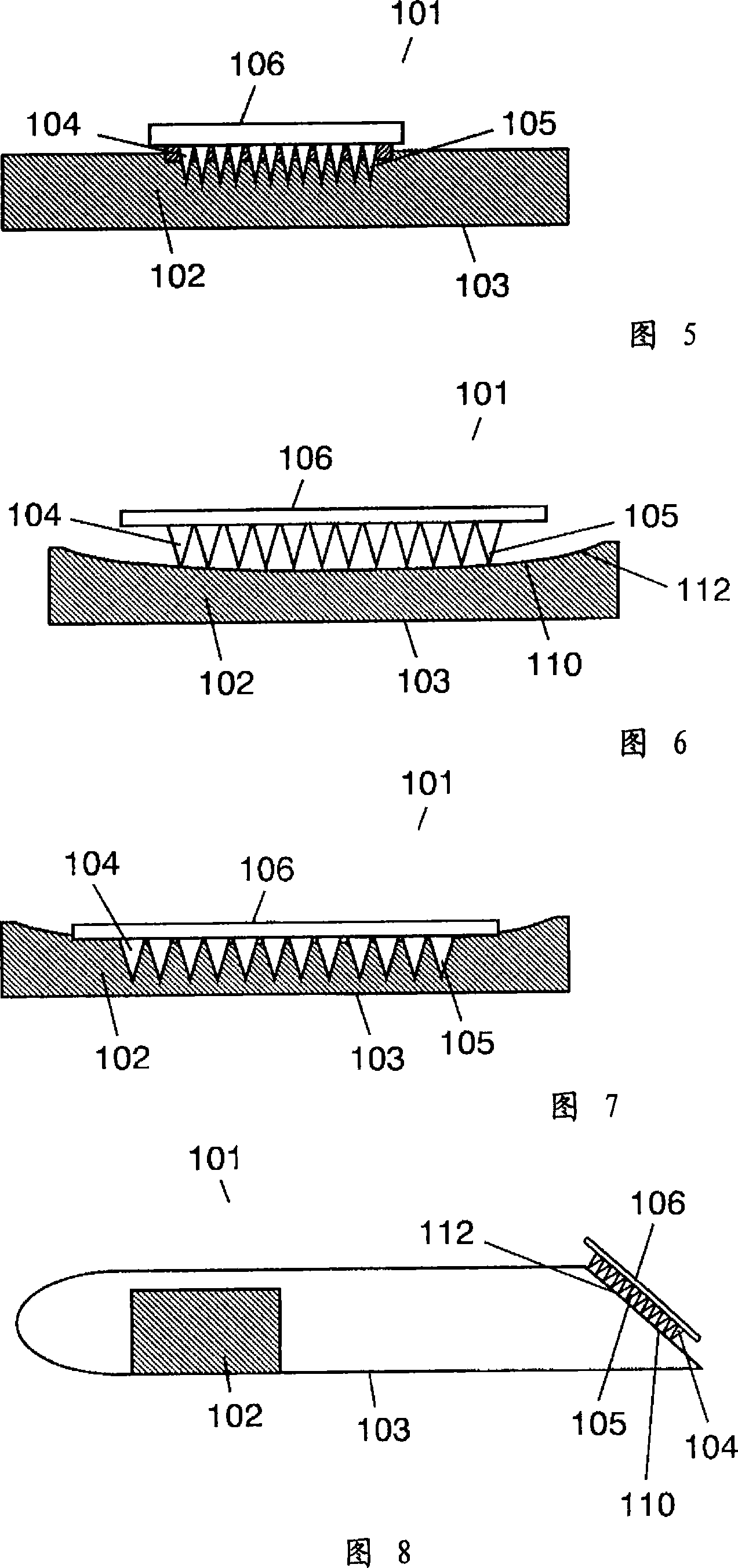

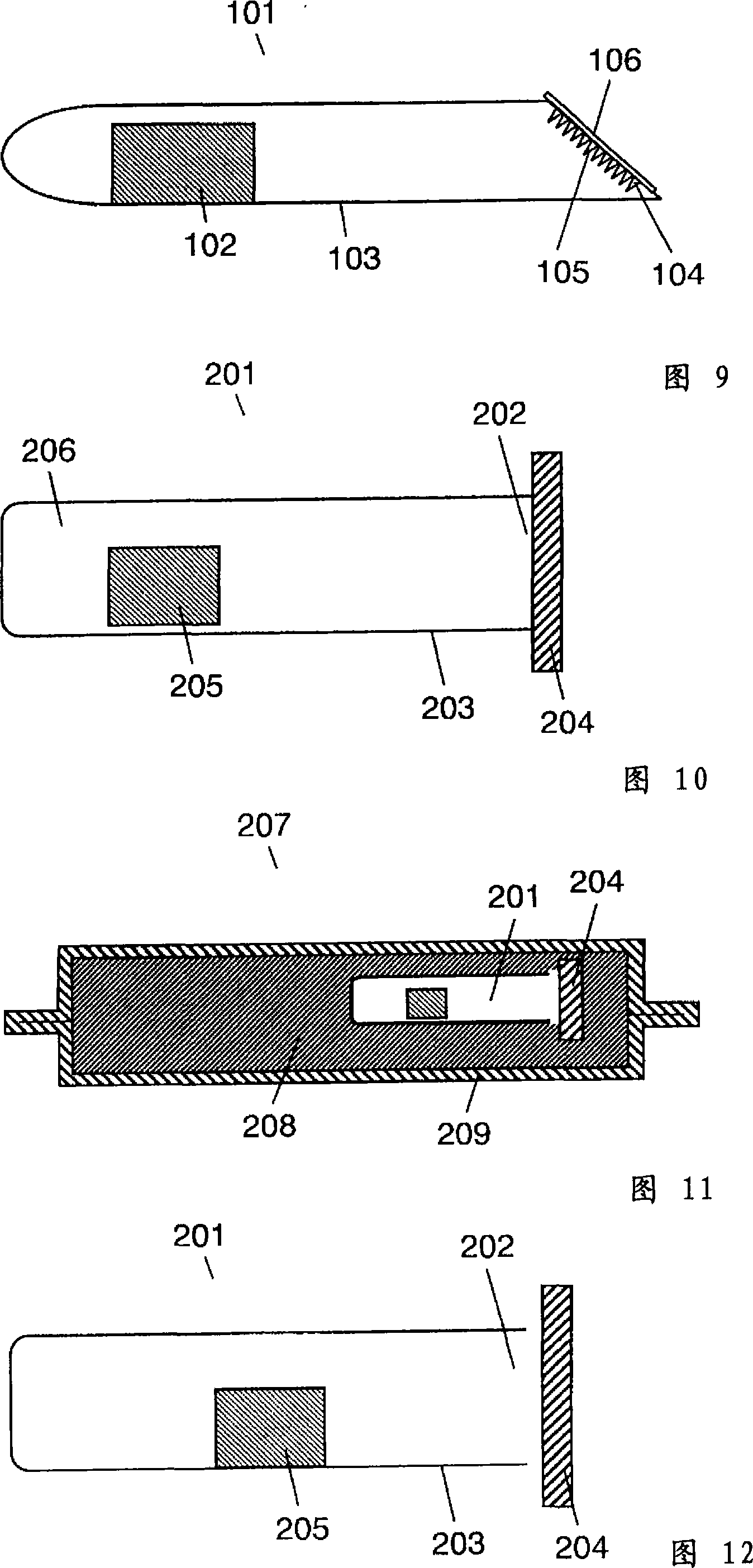

[0110] Fig. 1 is a cross-sectional view of a gas adsorption device according to Embodiment 1 of the present invention.

[0111] In FIG. 1 , a gas adsorption device 101 is equipped with a gas adsorption material 102 inside a container 103 , and a protrusion 104 is in contact with the container 103 . The gas adsorbent 102 is powdered CuZSM-5.

[0112]The container 103 is a bag made by thermally fusing low-density polyethylene, which is a laminated film of low-density polyethylene, aluminum foil, and polyethylene terephthalate, in this order. After 102, it is made by vacuum sealing. The protrusion 104 is in contact with the container 103 by means of the protrusion 105 . The protrusions 104 are fixed on the plate member 106, and the protrusions 105 are arranged in a two-dimensional plane.

[0113] Fig. 2 is a cross-sectional view of the vacuum insulator according to Embodiment 1 of the present invention.

[0114] In FIG. 2 , the vacuum insulator 107 is made by inserting the ga...

Embodiment approach 2

[0124] Fig. 4 is a cross-sectional view of a gas adsorption device 101 according to Embodiment 2 of the present invention.

[0125] In FIG. 4 , a container 103 has an opening 110 , and the opening 110 is covered with a rubber stopper 111 to ensure overall airtightness. The container 103 is made of polyethylene material, and the rubber stopper 111 is made of isobutylene rubber, and the elasticity of the rubber is used to ensure the tightness with the container 103 . In addition, the protrusion 105 of the protrusion 104 is provided so as to be in contact with the rubber stopper 111 .

[0126] Fig. 5 is a converted cross-sectional view of the gas adsorption device 101 according to Embodiment 2 of the present invention.

[0127] Next, the operation and function of the gas adsorption device 101 configured as above will be described.

[0128] First, since the gas adsorbent 102 is sealed with a rubber stopper and polyethylene, even if the gas adsorbent 101 is placed in the atmosphe...

Embodiment approach 3

[0132] Fig. 6 is a cross-sectional view of a gas adsorption device 101 according to Embodiment 3 of the present invention.

[0133] In FIG. 6 , a container 103 has an opening 110 , and the opening 110 is covered with a film 112 having gas barrier properties to ensure overall airtightness. The container 103 is made of polyethylene, and the film 112 is a laminated film of low-density polyethylene, aluminum foil, and polyethylene terephthalate in this order, and is bonded by a known method. In addition, the protrusion 105 of the protrusion 104 is provided in contact with the film.

[0134] Fig. 7 is a converted cross-sectional view of the gas adsorption device 101 according to Embodiment 3 of the present invention.

[0135] Next, the operation and function of the gas adsorption device 101 configured as above will be described.

[0136] First, since the gas-adsorbing material 102 is sealed with a gas-barrier film and polyethylene, even if the gas-adsorbing device 101 is placed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com