Full automatic high-efficiency pipe chute thickener

A fully automatic thickening machine technology, applied in the field of thickening machines, can solve the problems of high civil construction and equipment cost, low sedimentation efficiency of thickening machines, poor hydraulic conditions in the pool, etc., to achieve beautiful structure, quick signal response, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

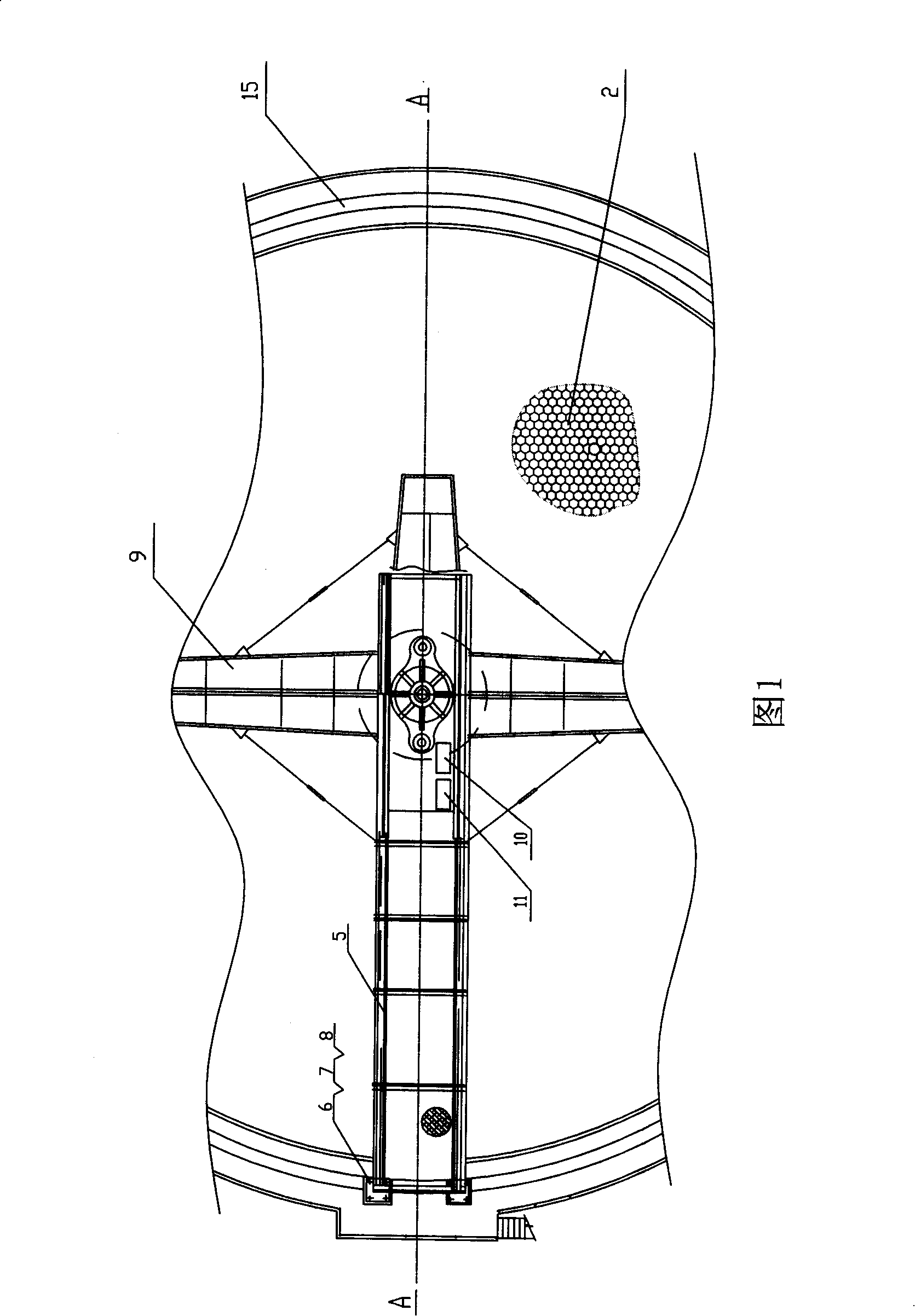

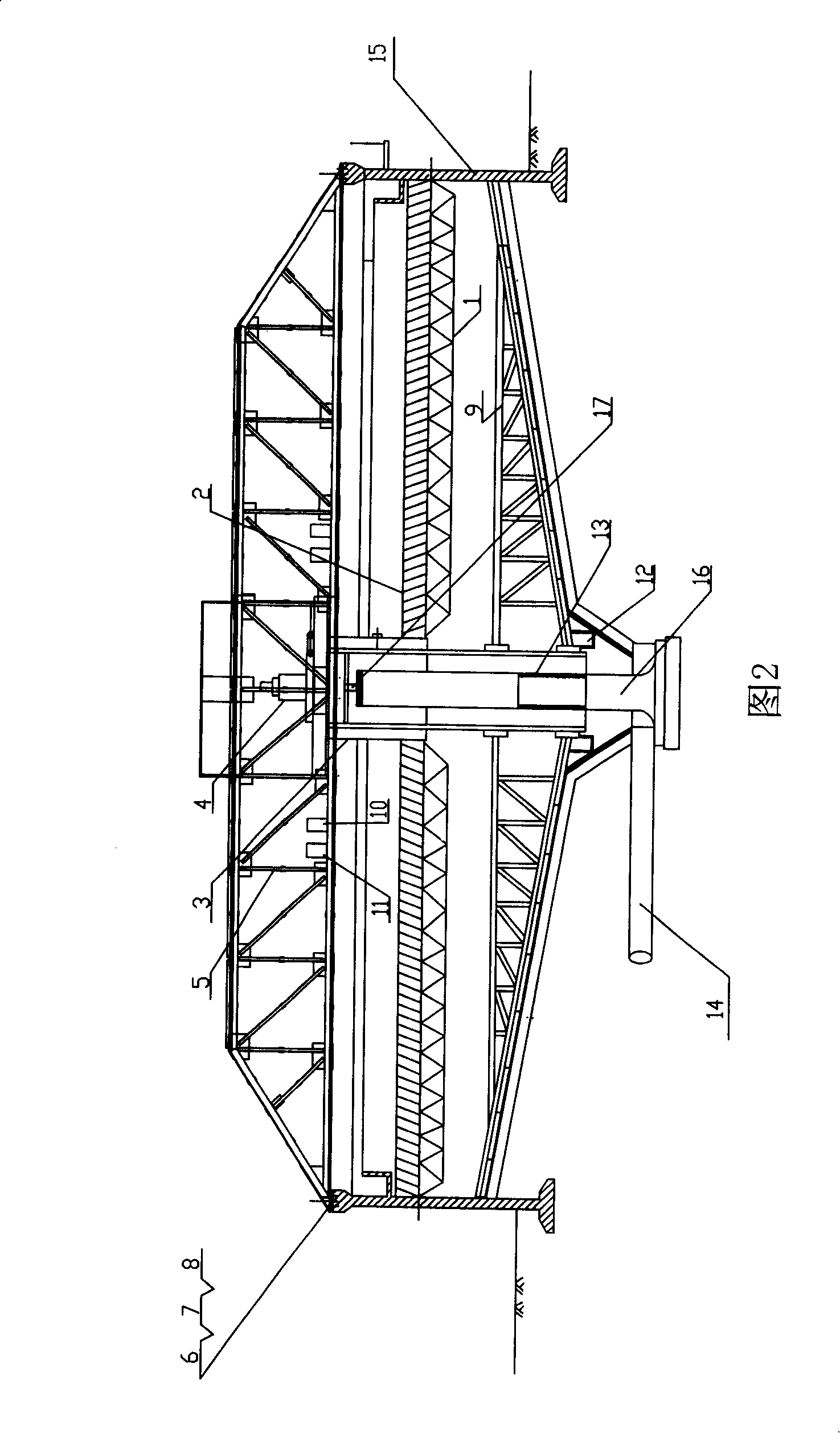

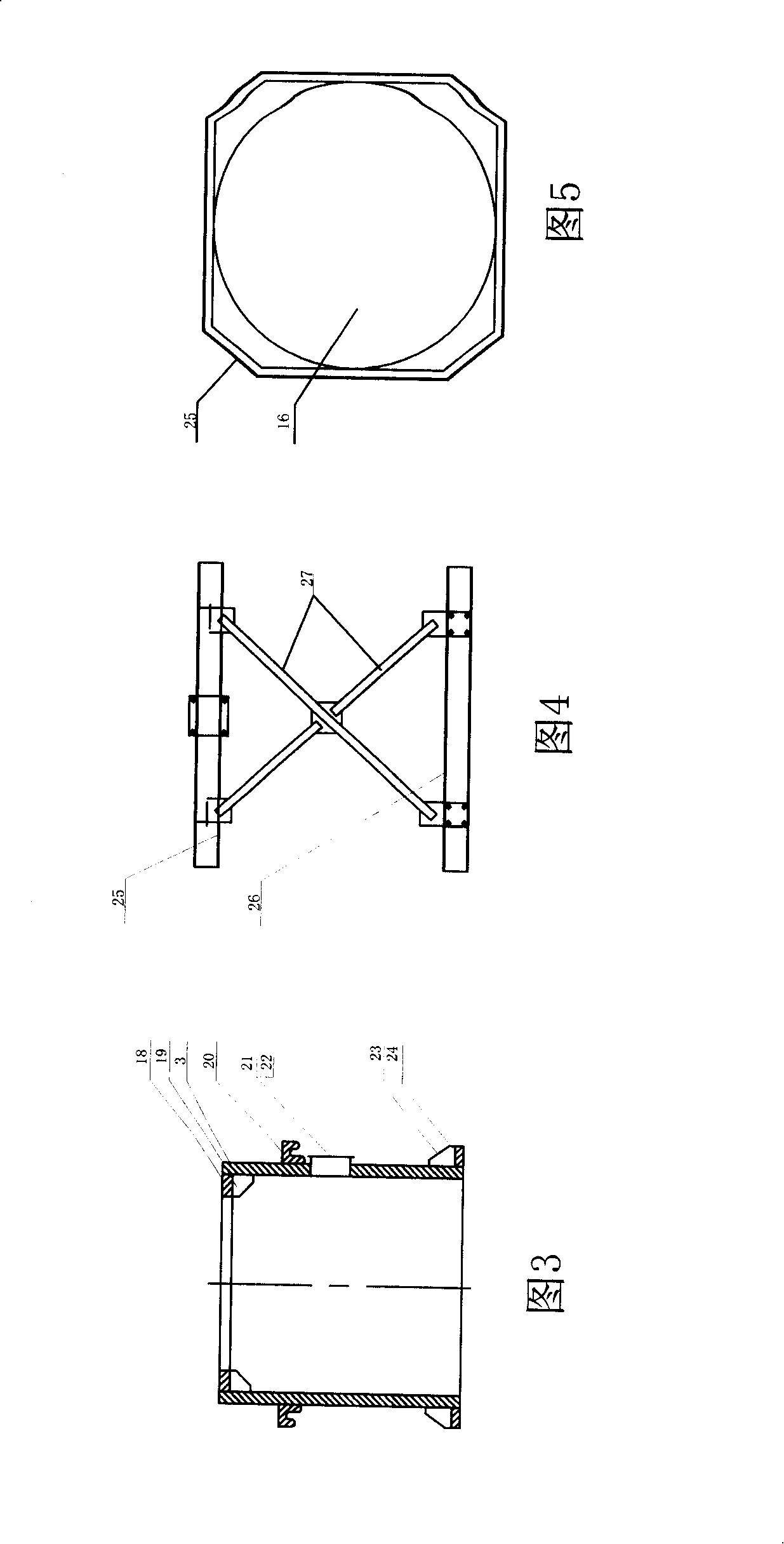

[0033] Next, the full-automatic high-efficiency inclined tube concentrator of the present invention will be described in detail below with reference to the accompanying drawings.

[0034] In the fully automatic high-efficiency inclined tube concentrator of the present invention, the two ends of the bridge frame 5 are fixed and overlapped on the circular concrete pool 15 by bolts 6, nuts 7, and gaskets 8, and the bottom of the pool is conical in design. A bottom flow pipe 14 is introduced; a central column 16 with a steel pipe sleeve 13 on the outer wall is erected at the center of the pool bottom, and the upper end of the central column 16 is connected to the middle of the bridge frame 5 through a central shaft 17, and the central column 16 and the central shaft 17 pass through bearings respectively. They are respectively connected to the bottom of the pool and the bridge frame 5. The electric control cabinet 11 and the hydraulic station 10 set on the bridge frame 5 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com