Bottle cap crusher

A technology of crusher and crushing mechanism, applied in grain processing and other directions, can solve the problems of easy injury, low efficiency, unenvironmental protection, etc., and achieve the effects of no dust, high efficiency, and prevention of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

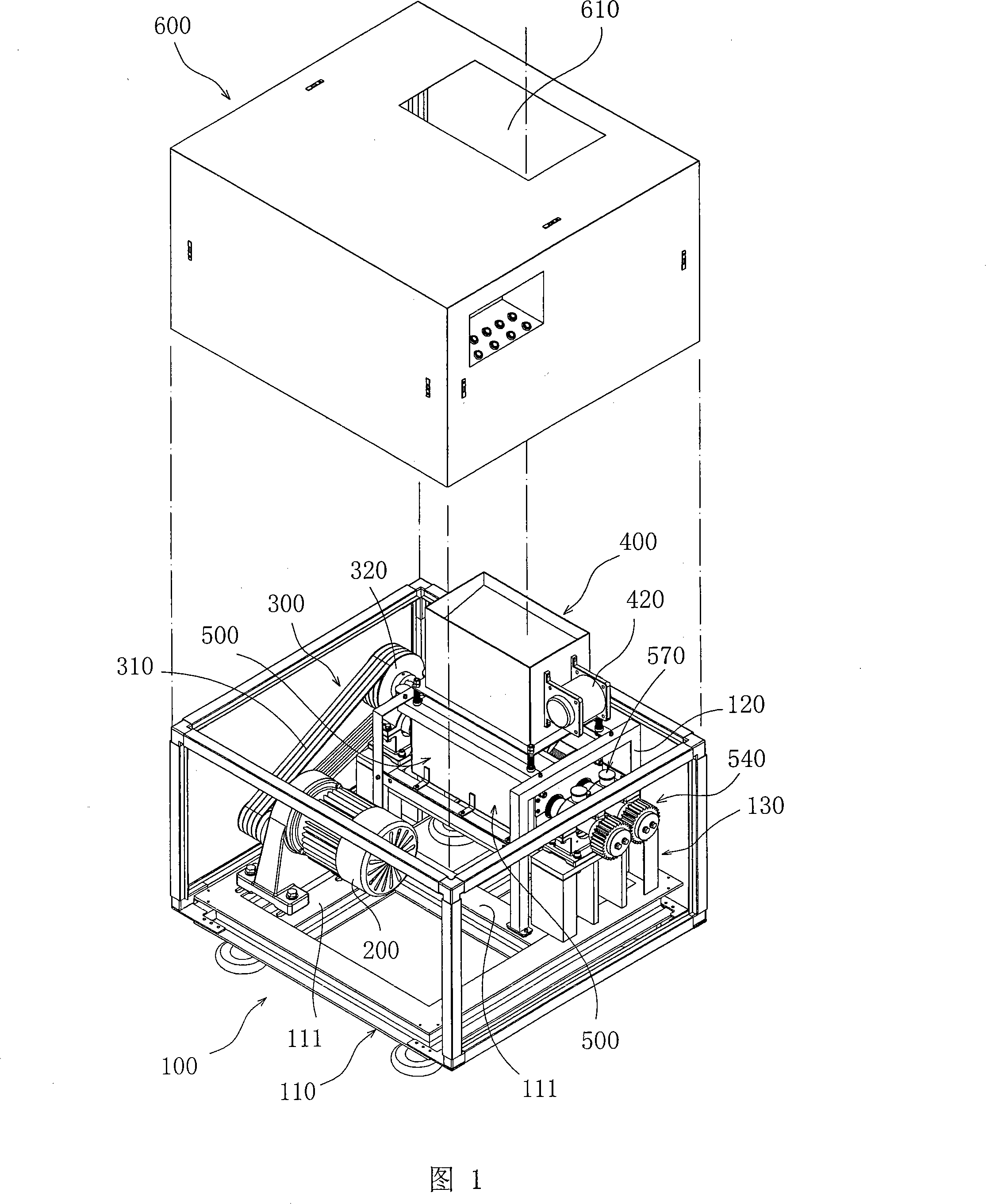

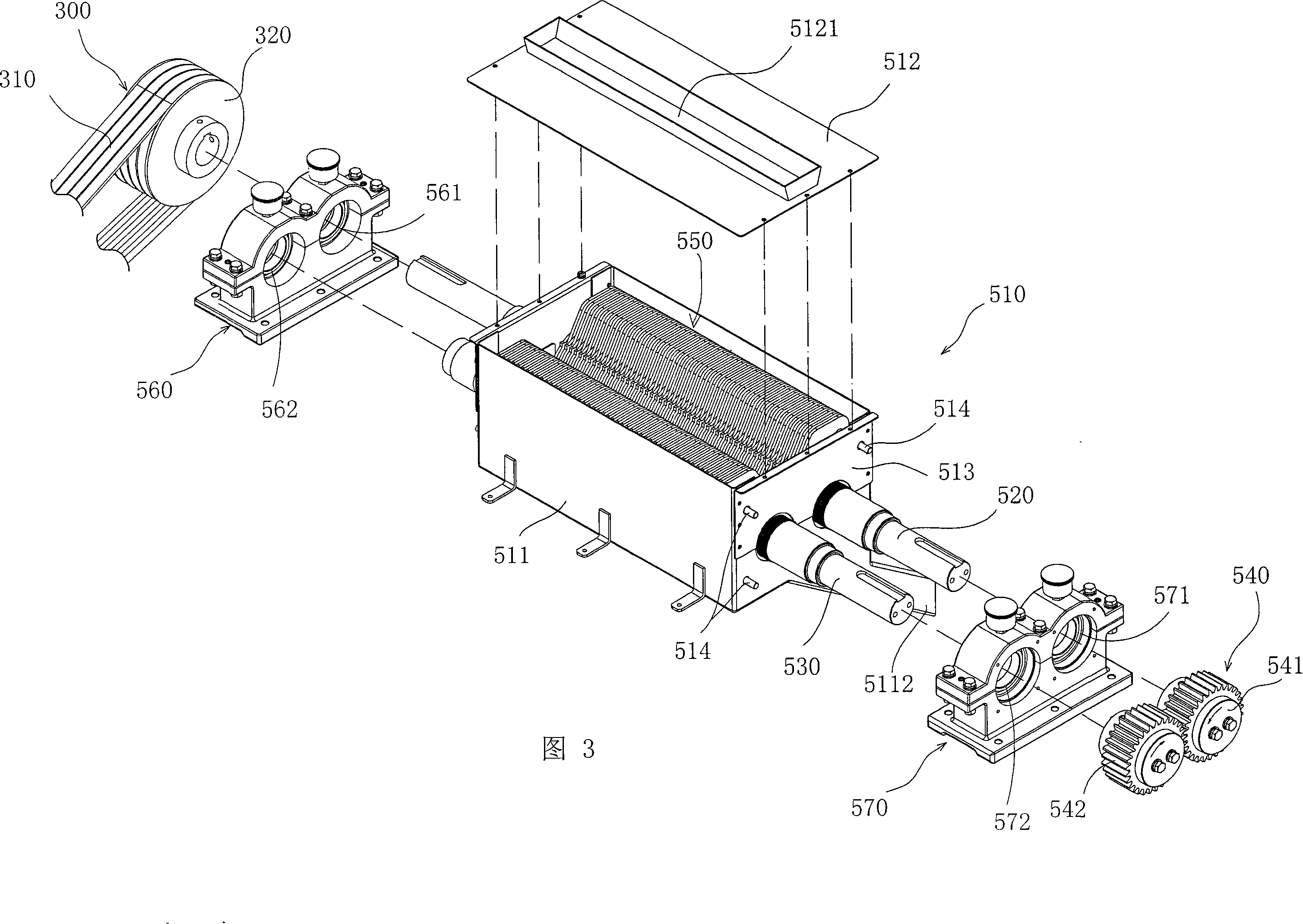

[0030] The bottle cap crusher of the present invention includes a frame 100, a soundproof cover 600, a motor 200, a transmission mechanism 300, a feeding mechanism 400, and a crushing mechanism 500. The motor, transmission mechanism, feeding mechanism and crushing mechanism are installed in the frame , The transmission mechanism connects the electric motor and the crushing mechanism, the feeding mechanism is arranged above the crushing mechanism, and the discharging hopper for discharging the crushed materials is also arranged below the crushing mechanism. The output end of the motor, which is started by an external power source, drives the driving shaft of the crushing mechanism in a conventional manner through a belt and a pulley.

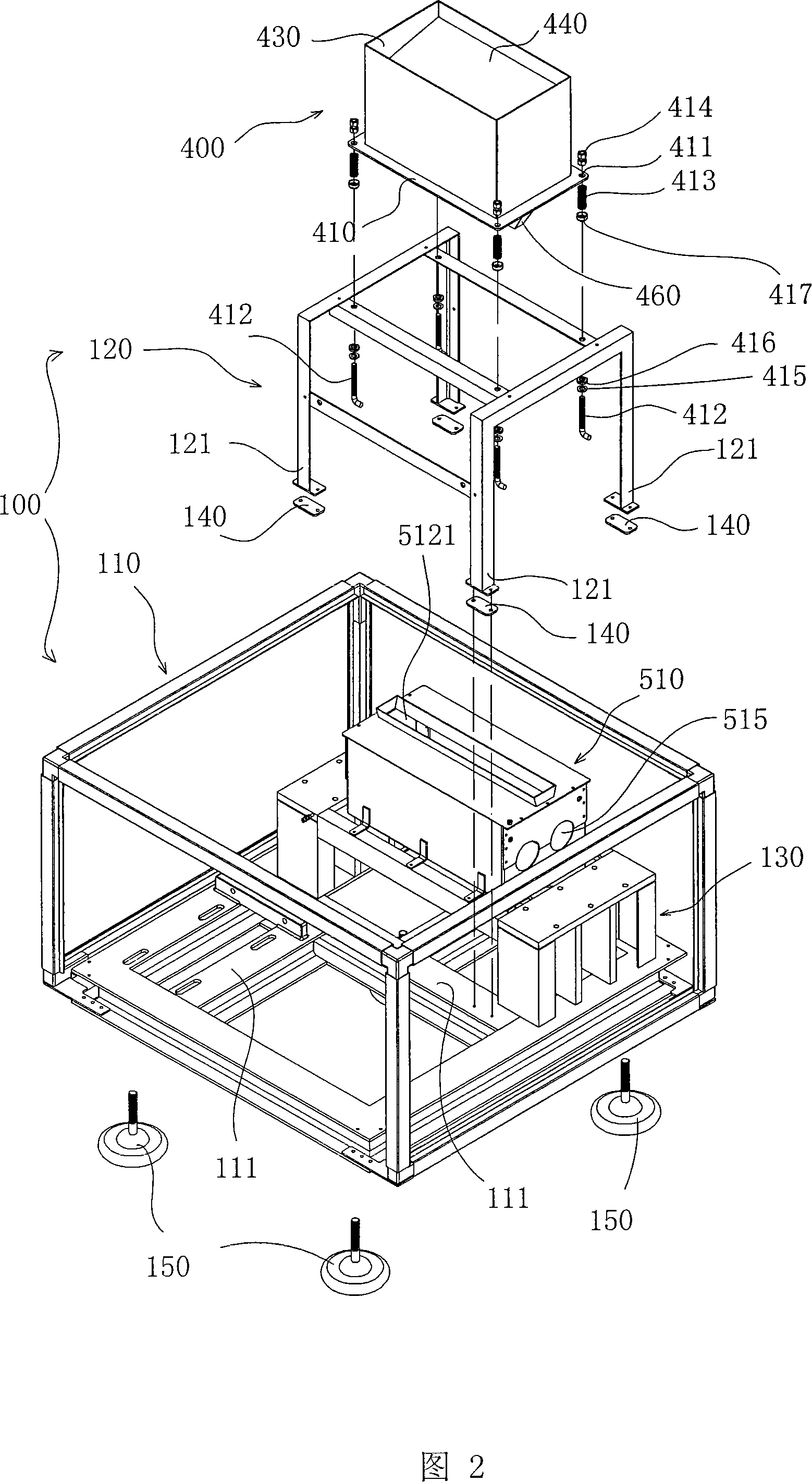

[0031] 1 and 2, the frame 100 includes a bottom frame 110 and a support frame 120. The bottom frame is a rectangular parallelepiped frame formed by connecting various angle steels and metal rods. The outer periphery of the frame is covered with a sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com