Wire cutting electric-discharge machining device of double three-dimension position coordinate system

A three-dimensional position, electrical discharge machining technology, used in electric machining equipment, metal processing equipment, electrode manufacturing, etc., to achieve the effect of low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

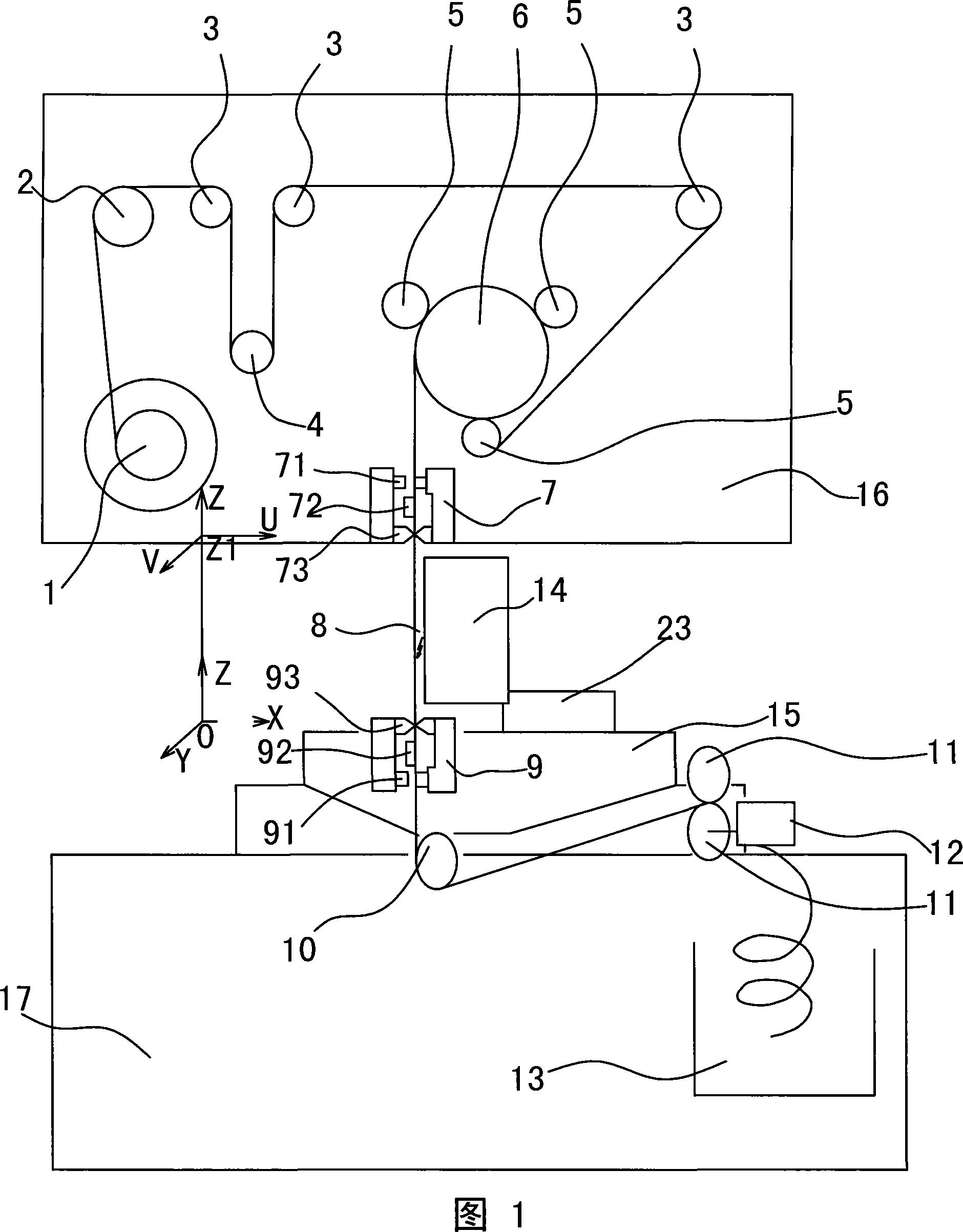

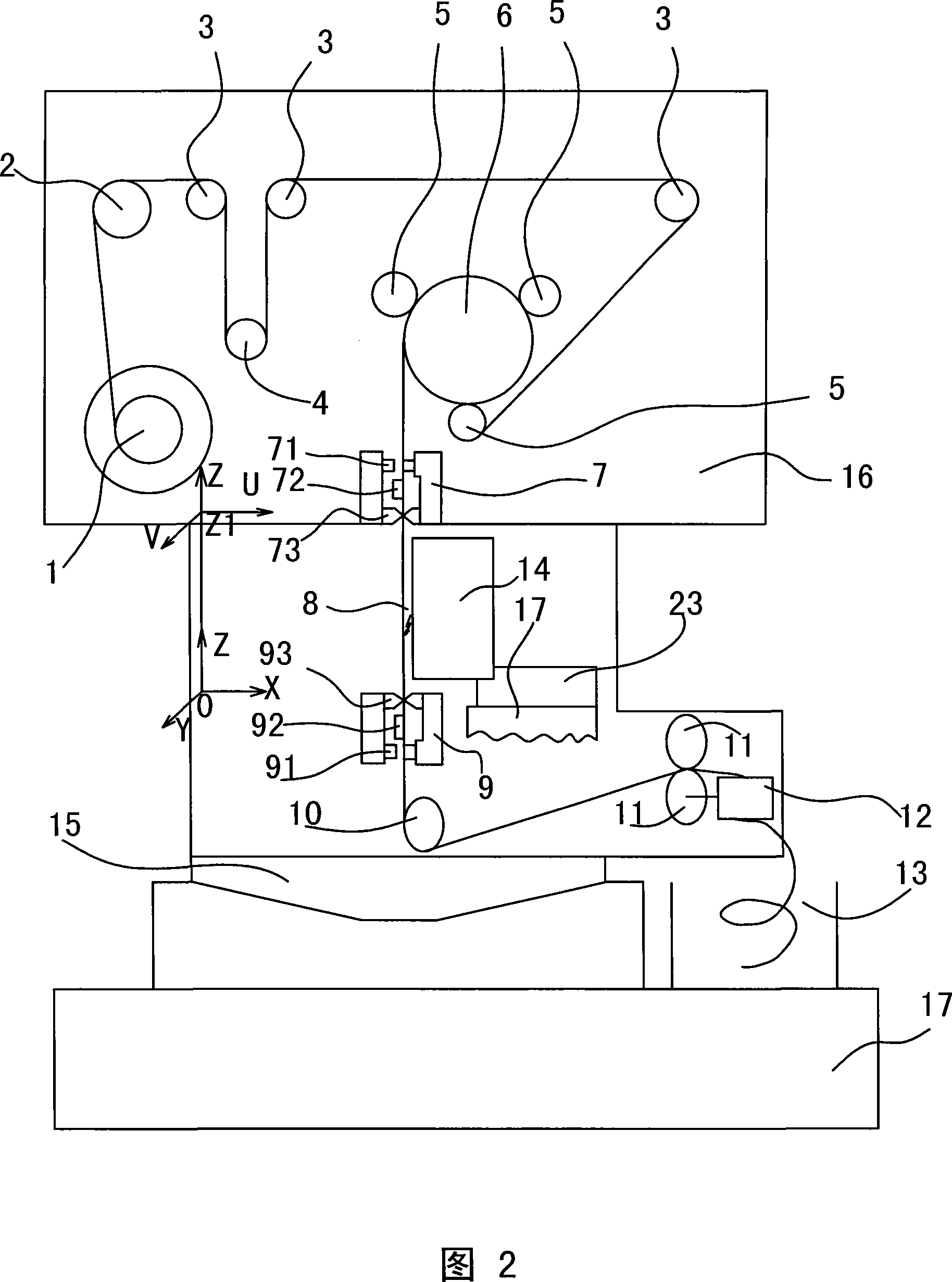

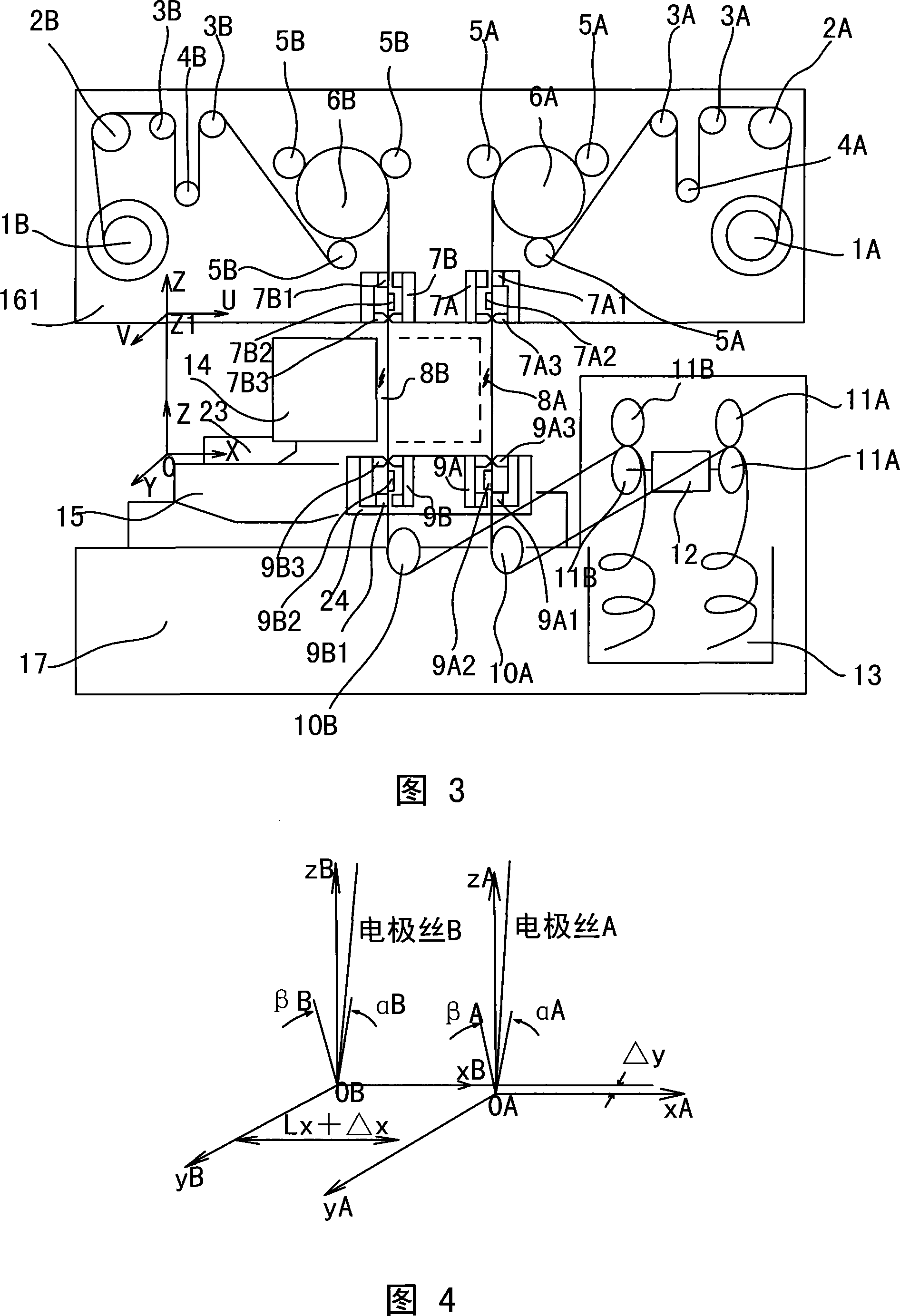

[0035] Embodiment 1: A double-three-dimensional position coordinate line cutting electric discharge machining device

[0036] As shown in Figure 3, the double three-dimensional position coordinate line cutting electric discharge machining device includes a bed 17, an X-Y axis movement carriage 15, a U-V-Z axis movement carriage and an upper guide wire assembly mounting plate 161, a workbench 23 and a lower guide wire assembly. Mounting plate 24. The U-V-Z axial movement carriage and the upper guide wire assembly mounting plate 161 are connected to the bed 17 through the column, the workbench 23 is installed on the X-Y axis movement carriage 15, the bottom surface of the X-Y axis movement carriage 15 is connected with the bed 17, and the lower The guide wire assembly mounting plate 24 is fixedly arranged on the bed 17 through the lower wire arm. The workpiece 14 is mounted on the workbench 23 and located between the upper guide wire assembly mounting plate 161 and the lower gu...

Embodiment 2

[0040] Embodiment 2: Another double-three-dimensional position coordinate system wire-cut electric discharge machining device.

[0041] As shown in Figure 5, another double-three-dimensional position coordinate system wire-cut EDM device includes a bed 17, an X-Y axis moving carriage 15, a U-V-Z axis moving carriage and an upper guide wire assembly mounting plate 161, a workbench 23, The lower guide wire assembly mounting plate 24 and two sets of wire feeding mechanisms that cannot be used at the same time. The two sets of wire feeding mechanisms have their own feeding and receiving parts and upper and lower wire guide assemblies. The two upper guide wire assemblies of the two sets of wire feeding mechanisms are all installed on the upper guide wire assembly mounting plate 161 in front of the same U-V-Z axis moving carriage. The two lower guide wire assemblies of the two sets of wire feeding mechanisms are all installed on the same lower guide wire assembly mounting plate 24 ...

Embodiment 3

[0044] Embodiment 3: This embodiment is a practical improvement of the first embodiment. Both sets of wire feeding mechanisms adopt unidirectional low-speed wire feeding mechanisms.

[0045] In the first embodiment, two sets of completely separated and independent wire feeding components are used, and the two three-dimensional position coordinate systems have a fixed difference Lx in the X-axis direction in the horizontal plane. The two lower guide wire assemblies 9A, 9B are all fixed on the lower guide wire assembly mounting plate 24, and the lower guide wire assembly mounting plate 24 is installed on the front end of the upper wire arm fixed on the bed. Due to the limitation of the size of the front end of the lower wire arm and the size of the lower guide wire assembly mounting plate 24, Lx is generally controlled at a value of about 80-150mm, and the diameter of the polyurethane wheel equipped with a tension controller is also at this value within range. In addition, in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com