Special stainless clad steel sill for elevators and forming process thereof

A molding process, stainless steel technology, applied in elevators, transportation and packaging in buildings, etc., can solve the problems of easy oxidation, high cost, unsightly appearance, etc., and achieve the effect of low cost, simple production and durable appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

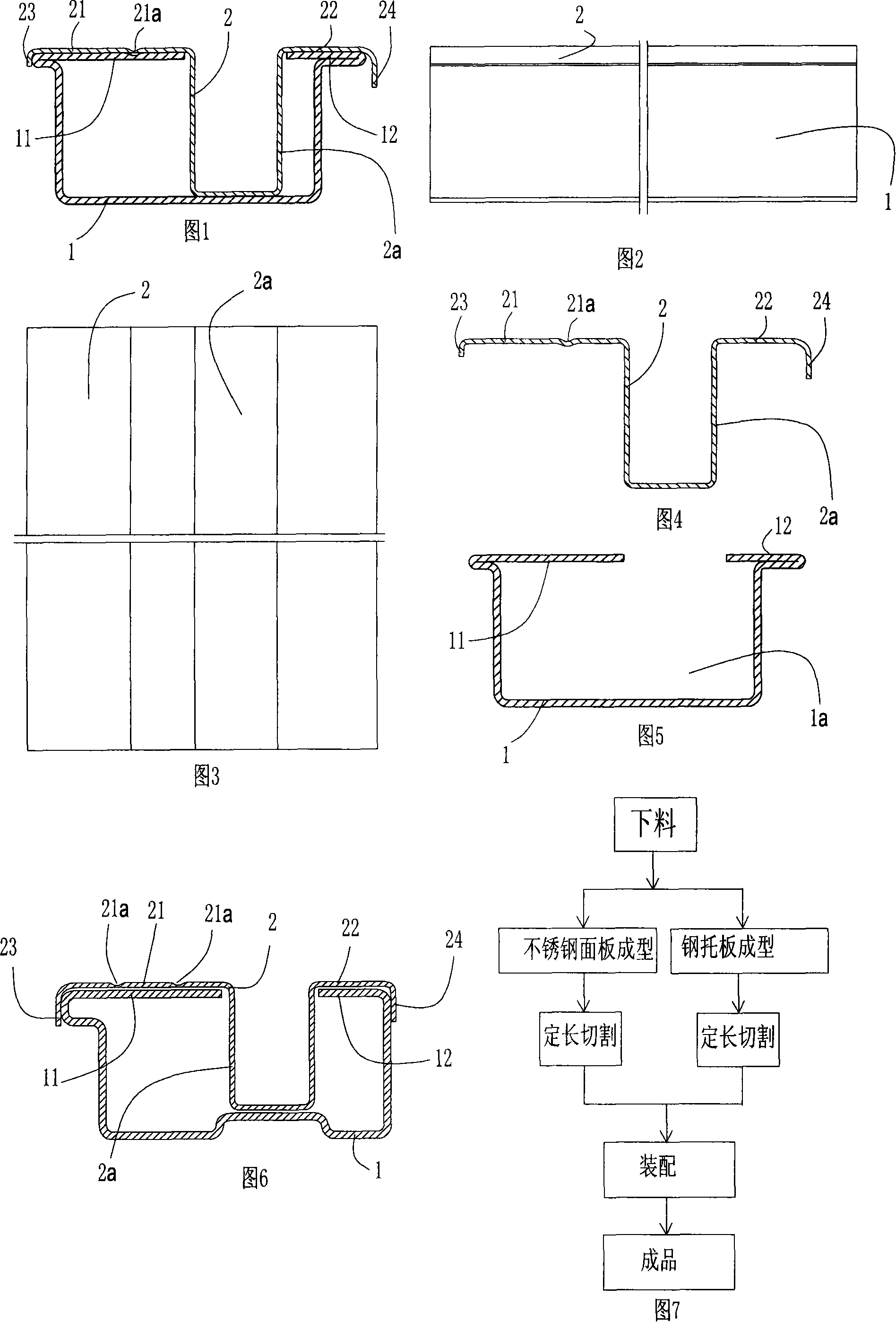

[0028] The embodiment shown in Fig. 1 to Fig. 7, reference number description: steel supporting plate 1, plate cavity 1a, first supporting plate end 11, second supporting plate end 12, stainless steel panel 2, groove body 2a, first Panel end 21 , anti-slip groove 21 a , second panel end 22 , first folded edge 23 , second folded edge 24 .

[0029] As shown in Figures 1 to 5, an anti-skid groove is formed in the embodiment of the present invention, and the special stainless steel composite floor sill for elevators includes a steel supporting plate 1 installed on the floor door of the elevator and the floor beam of the car door, and the top of the steel supporting plate 1 A first pallet end 11 and a second pallet end 12 are formed, and a plate cavity 1a extending to the inner bottom of the steel pallet 1 is formed between the first pallet end 11 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com