Vacuum closet discharging device

A technology for vacuum toilets and equipment, which is applied to flushing equipment with water tanks, water supply devices, buildings, etc., can solve the problems of humid use environment, increased water consumption, unstable use performance, etc., and achieve stable operation performance and overall performance improvement. , good suction and discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

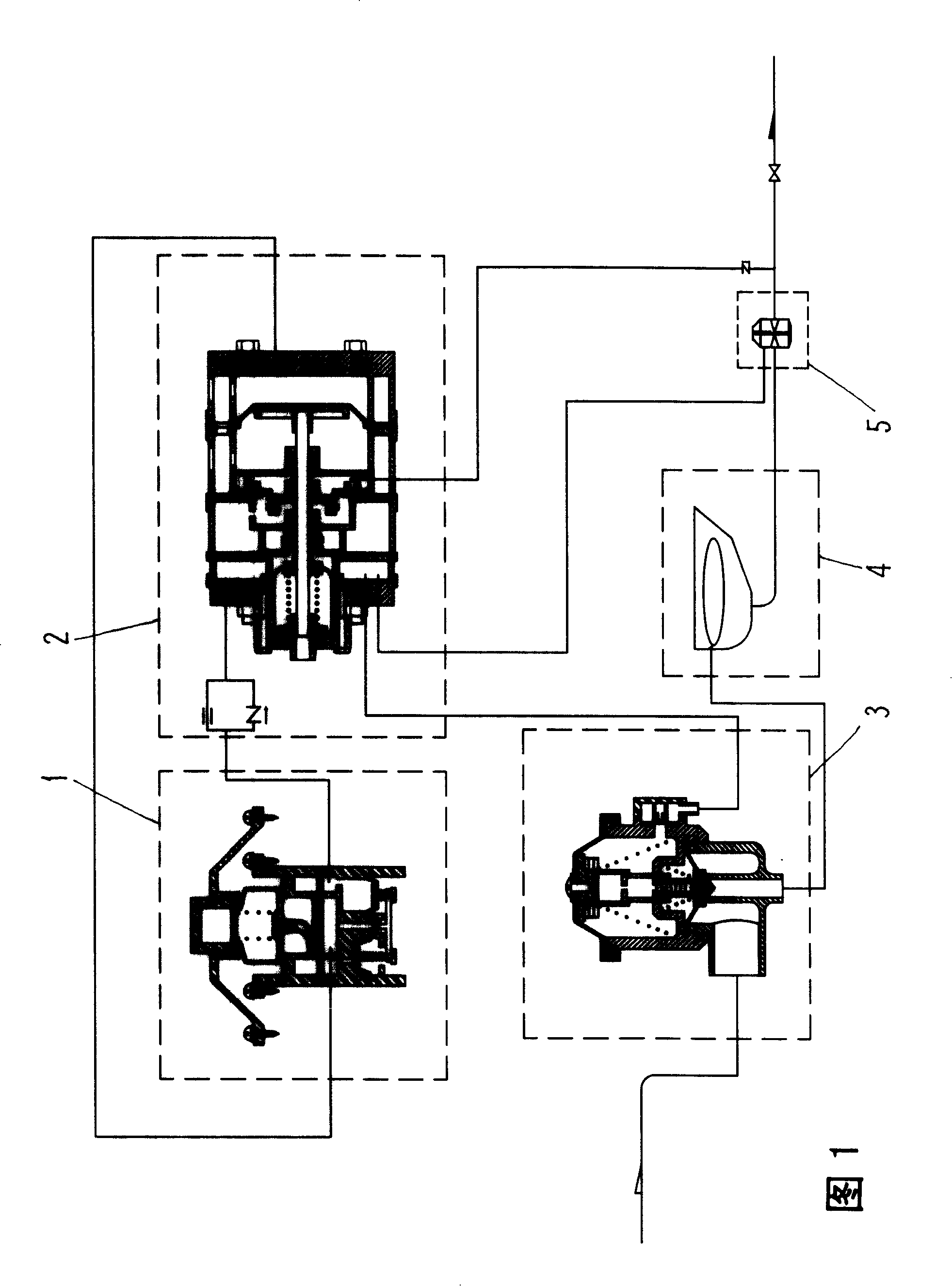

[0014] Referring to Fig. 1, the vacuum toilet discharge equipment includes a starting mechanism 1, an actuator 2, a flush valve 3, a vacuum toilet 4, a vacuum discharge valve 5 and a collection cabinet (not shown); the starting mechanism 1 is connected to the actuator 2 through a pipeline , the actuator 2 is respectively connected with a flush valve 3 and a vacuum discharge valve 5 through a pipeline, the flush valve 3 is connected with a vacuum toilet 4 through a pipeline, the vacuum toilet 4 is connected with a vacuum discharge valve 5 through a pipeline, and the vacuum discharge valve 5 is connected with a feces collection cabinet.

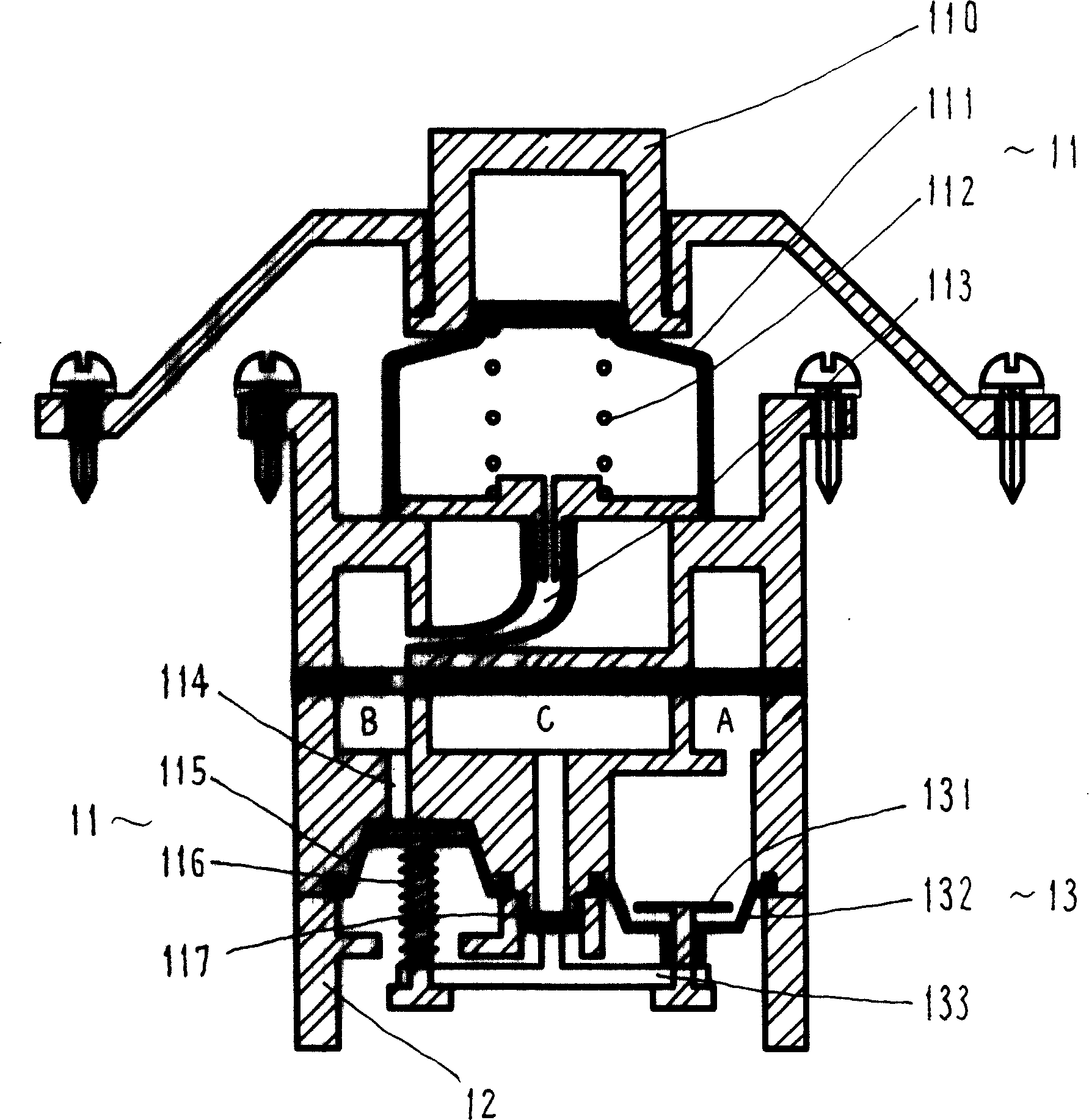

[0015] The starting mechanism 1, as shown in Figures 1 and 2, includes a starting action assembly 11, a cylinder body 12 and a reset assembly 13, wherein:

[0016] The starting action assembly 1 includes a button 110, an air bag 111, a spring 112, a conduit 113, a channel 114, a starting membrane 115, a starting lever 116, and an intake valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com