Magneto-rheologic damping control method

A magnetorheological damping and control method technology, applied in vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of magnetorheological damping devices such as large volume and weight, no breakthrough research progress, and difficulty in meeting the requirements. Compact, well-cushioned, fast-response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

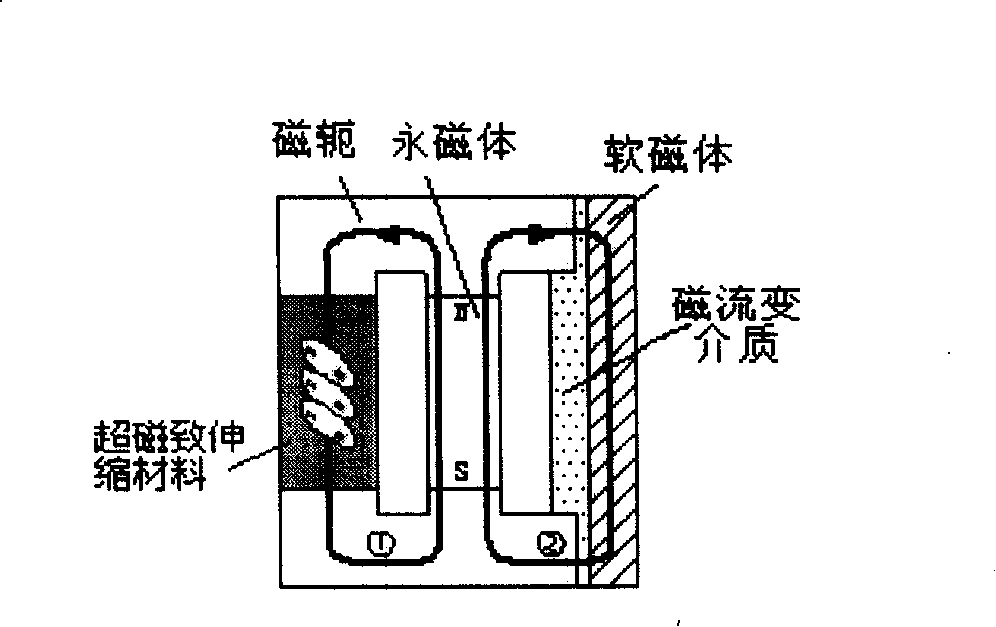

[0014] Embodiment 1: This magneto-rheological damping control method: use giant magnetostrictive materials, permanent magnets and yokes at both ends to form an input magnetic circuit, and use permanent magnets, yokes, magnetorheological media and soft magnets to form an output magnetic circuit .

Embodiment 2

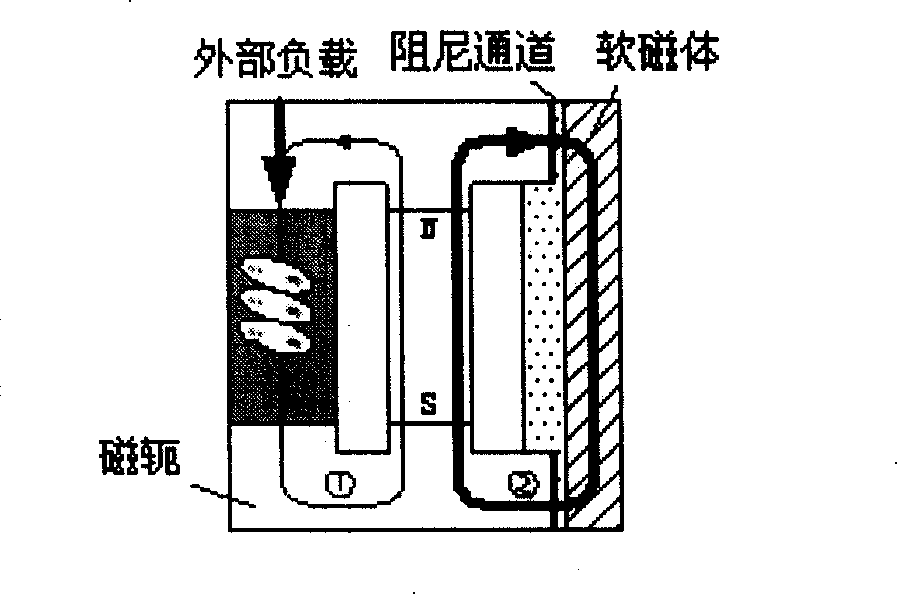

[0015] Embodiment 2: Before the method in Embodiment 1, add the step of loading an external load on the giant magnetostrictive material in advance.

Embodiment 3

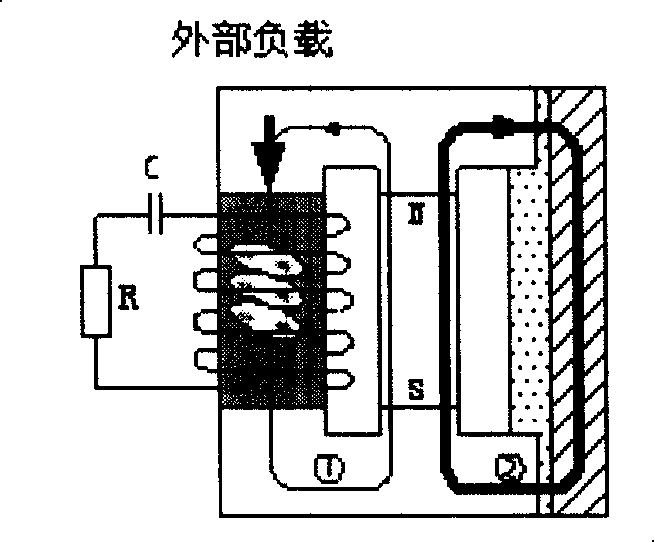

[0016] Embodiment 3: Before the method in embodiment 1, add a step of winding a coil on the giant magnetostrictive material, and the coil is connected to a circuit composed of a capacitor and a resistor in series.

[0017] When an external load is applied to the giant magnetostrictive material, its internal magnetic domain deflects in a direction perpendicular to the direction of the applied force, resulting in a decrease in its internal magnetization, so the magnetic flux of the output magnetic circuit decreases, because the total magnetic flux remains unchanged , so the magnetic flux input to the magnetic circuit increases, and the damping of the magnetorheological medium increases under the action of the magnetic field, and the greater the load, the greater the increase in the magnetic flux input to the magnetic circuit, and the greater the damping force of the magnetorheological medium. Therefore, the above method has its own advantages. Characterized by adaptability, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com