Double coil various current control method for vacuum breaker permanent magnetism mechanism

A technology of vacuum circuit breaker and permanent magnet mechanism, applied in the direction of protection switch operation/release mechanism, electromagnet, electromagnet with armature, etc., which can solve the problem of long operating time, insufficient opening speed, scattered opening and closing time to reduce the kinetic energy and collision speed of the iron core and improve the electrical life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

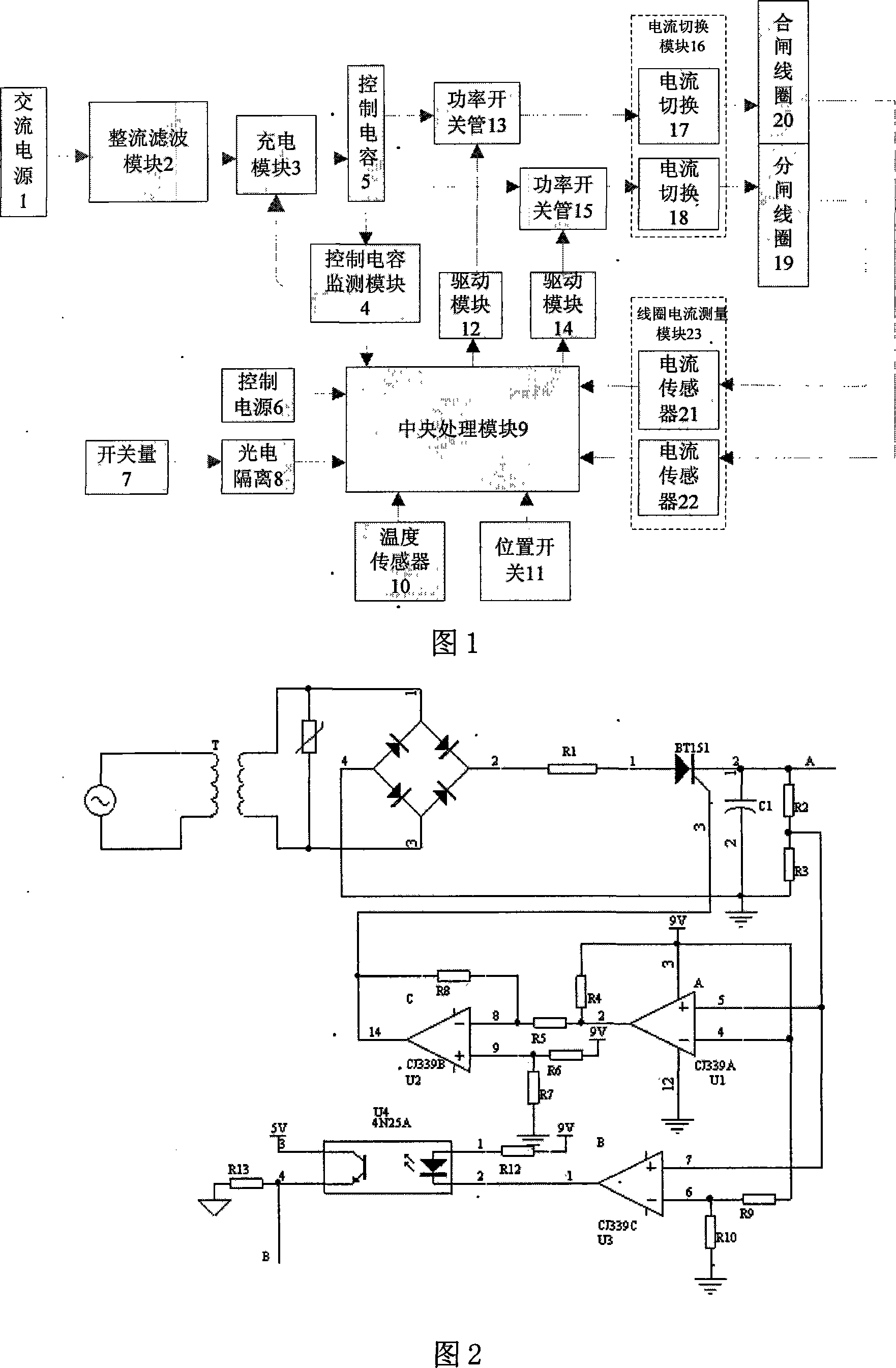

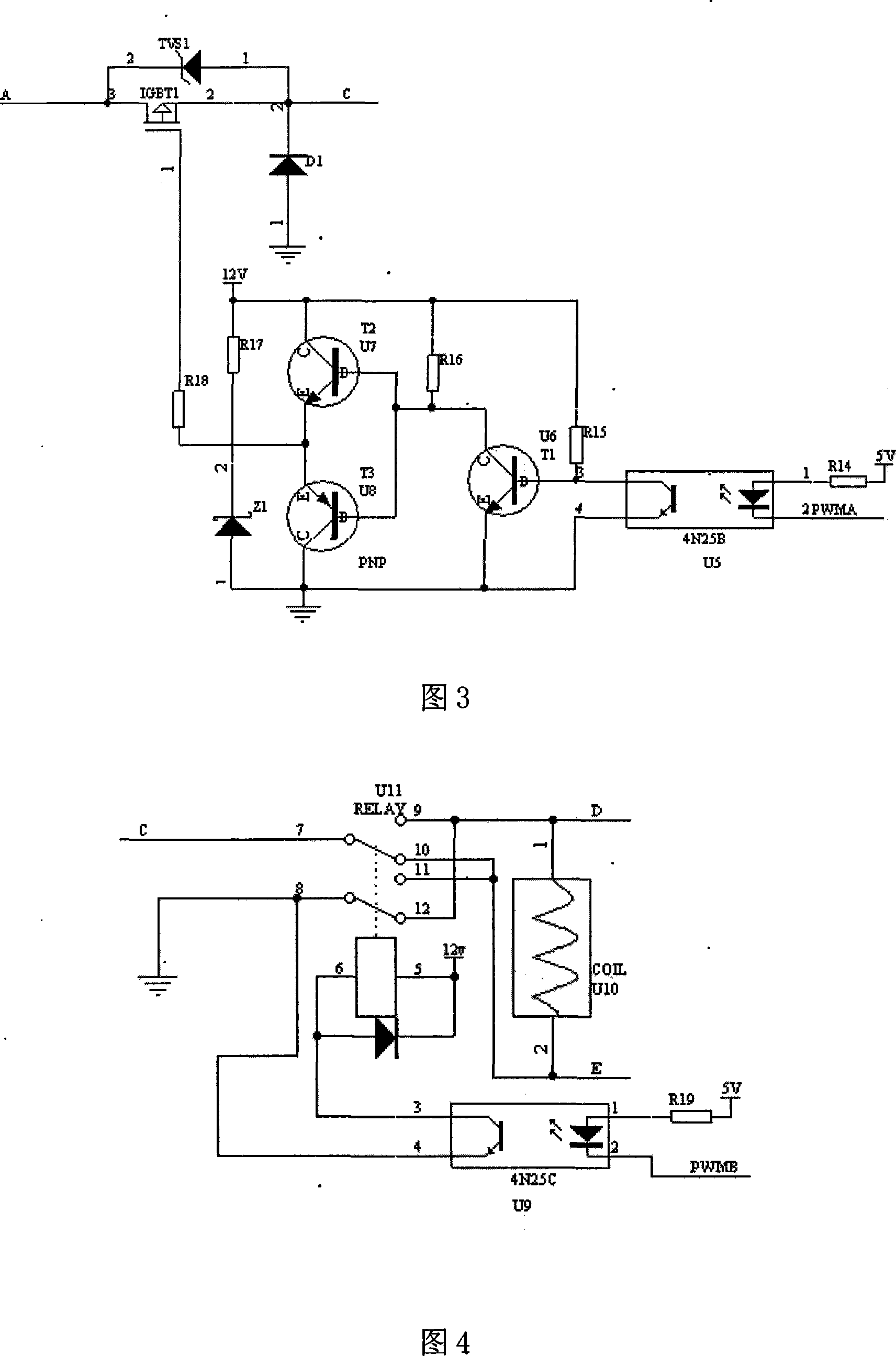

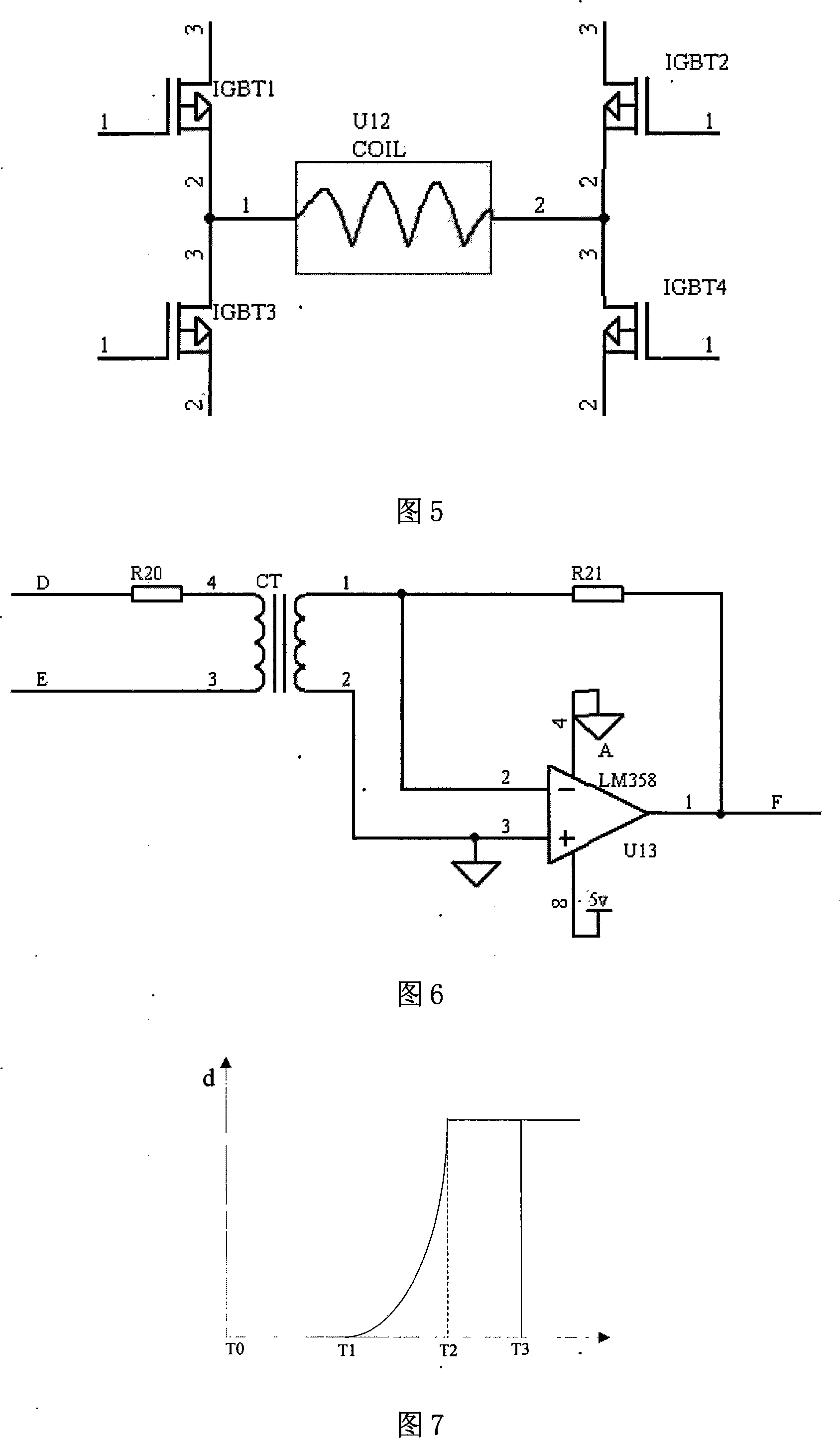

[0024] Referring to Fig. 1, the present invention comprises the rectifying and filtering module 2 that is connected with AC power supply 1, the output end of this rectifying and filtering module 2 is connected with the current input end of charging module 3, the output end of charging module 3 is connected with the input of control capacitor 5 The voltage feedback terminal of the control capacitor 5 is connected with the input terminal of the control capacitance detection module 4, the signal output terminal of the capacitance detection module 4 is connected with the signal input terminal of the charging module 3, and the other output terminal of the capacitance detection module 4 It is connected to the signal input end of the central processing module 9 for monitoring and controlling the state of the control capacitor detection module 4, and the current outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com