Flow turning-back gas liquid cross-flow super-gravitational field revolving bed equipment

A high-gravity field and baffle-type technology, applied in chemical/physical/physical-chemical mobile reactors, fractionation, etc., can solve problems such as inefficient use of space, small gas circulation area, and small gas-liquid flow, etc., to achieve The effects of reduced energy consumption, reasonable structure, and improved mass transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

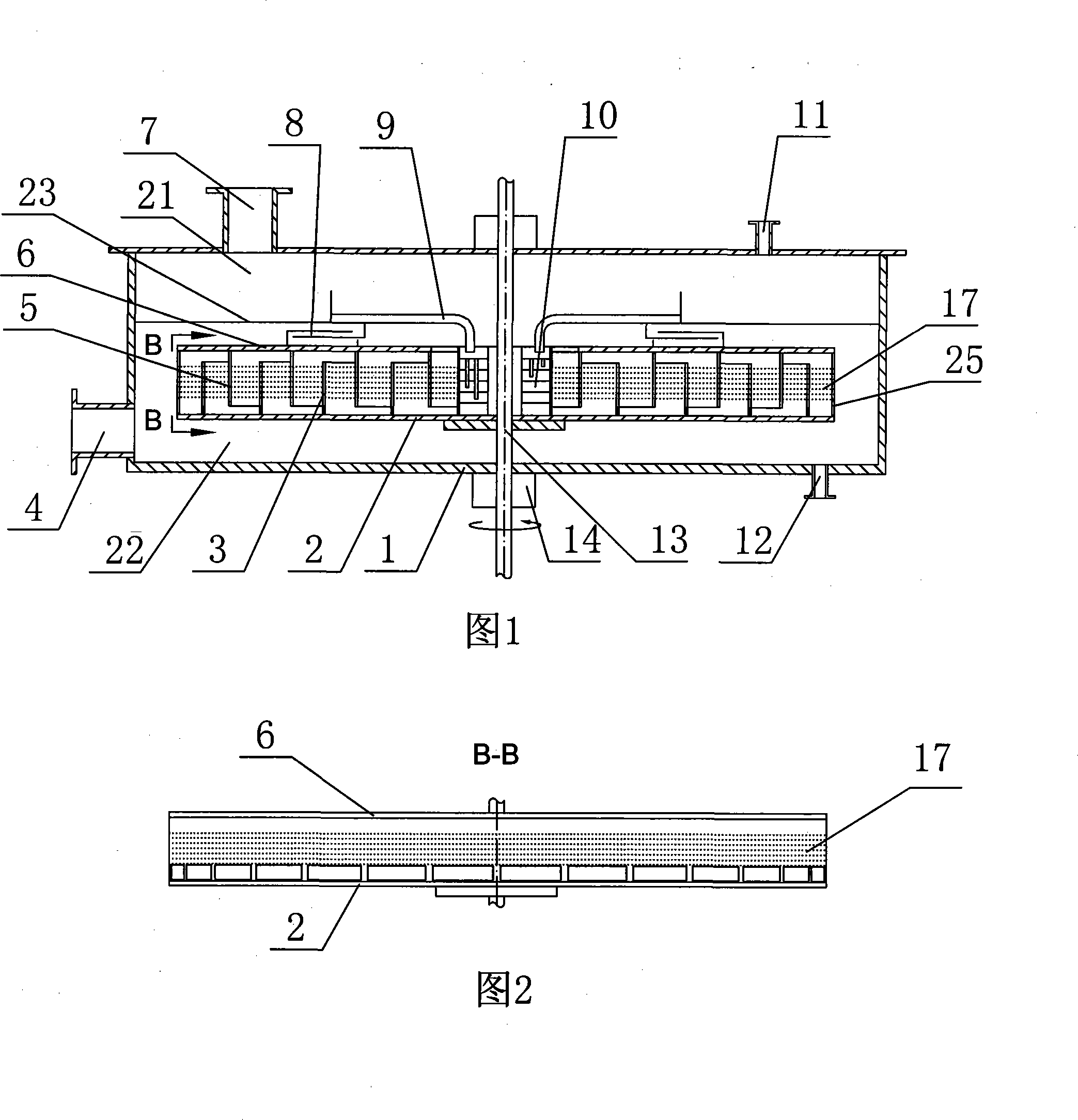

[0017] Embodiment 1: single-layer structure

[0018] As shown in Figure 1 and Figure 2, this baffle type gas-liquid cross-flow type supergravity field rotating bed device mainly includes a shell 1, a lower end plate 2, a lower concentric ring 3, a gas inlet 4, an upper concentric ring 5, Upper end plate 6 , gas outlet 7 , catheter 9 , liquid distributor 10 , liquid inlet 11 , liquid outlet 12 and rotating shaft 13 . The housing 1 is divided into an upper chamber 21 and a lower chamber 22 by a partition plate 23. The housing 1 is provided with a gas inlet 4, a liquid outlet 12, a gas outlet 7 and a liquid inlet 11, wherein the gas outlet 7 and the liquid inlet 11 The gas inlet 4 and the liquid outlet 12 communicate with the lower cavity 22 respectively. The rotating shaft 13 runs through the housing 1, and the rotor is composed of an upper end plate 6 fixedly connected with the rotating shaft 13, a lower end plate 2, an upper concentric ring 5, a lower concentric ring 3, and a...

Embodiment 2

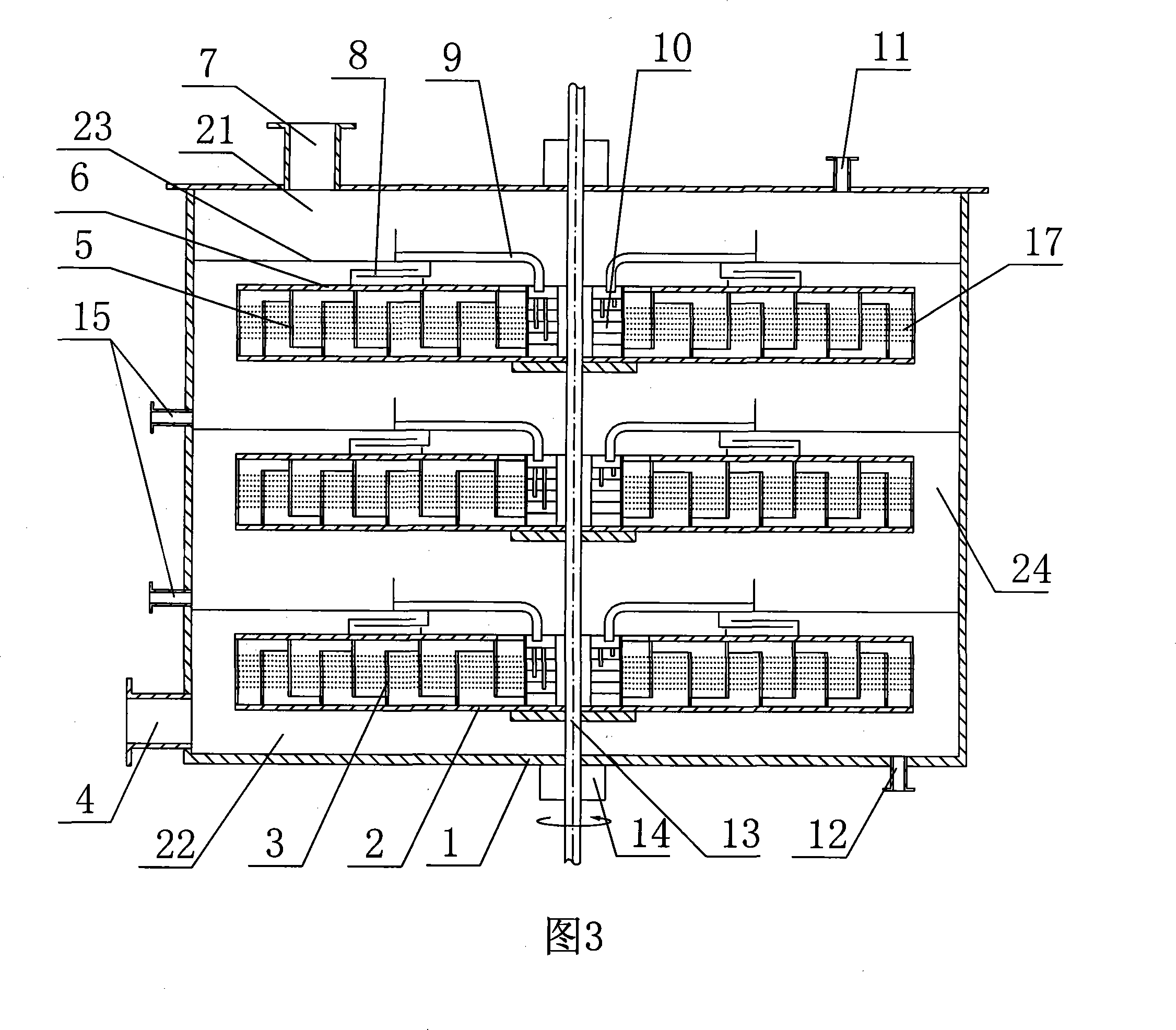

[0021] Embodiment 2: multi-layer structure

[0022] As shown in Figure 3, the housing 1 is divided into an upper cavity 21, a second-layer intermediate cavity 24 and a lower cavity 22 by a partition plate 23, and the intermediate cavity 24 is provided with an intermediate feed port 15 to form a multi-layer baffle structure. Multiple rotors are coaxially connected in series in a single housing. The gas-liquid flow in each rotor is the same as that of a single-layer structure. The difference is that the gas leaving the center of a rotor will enter the outer edge of the adjacent upper rotor again, and then After passing through the upper rotor along the zigzag path, it enters another rotor above it; the liquid leaving this rotor is collected and enters the distributor 10 of the next rotor through the duct 9 of the adjacent rotor, Under the action of centrifugal force, it passes through the next layer of rotors and then enters the next layer of rotors. In this way, in the struct...

Embodiment 3

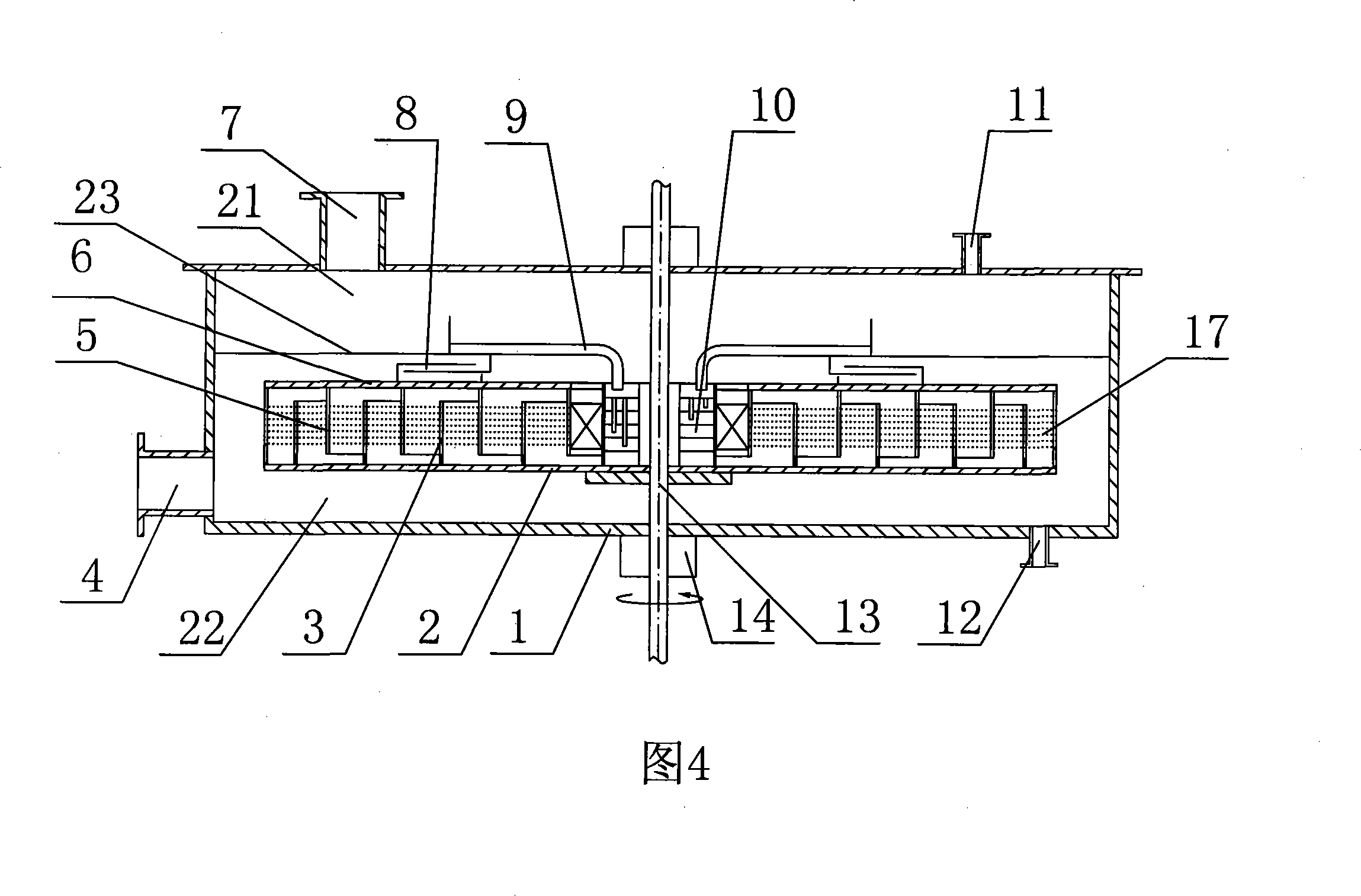

[0023] Embodiment 3: single-layer or multi-layer structure

[0024] As shown in Figure 4, when applied to gas-liquid mass transfer occasions, the last baffle area experienced by the gas at the center of each layer of rotor can be filled with packing 16, which can effectively prevent mist entrainment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com