Ball screw anti-dust device

A dust-proof device, ball screw technology, applied in transmission, chemical instruments and methods, belts/chains/gears, etc., can solve problems such as ineffectiveness, affecting the service life of the ball screw, and unable to prevent small iron filings from entering the nut, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

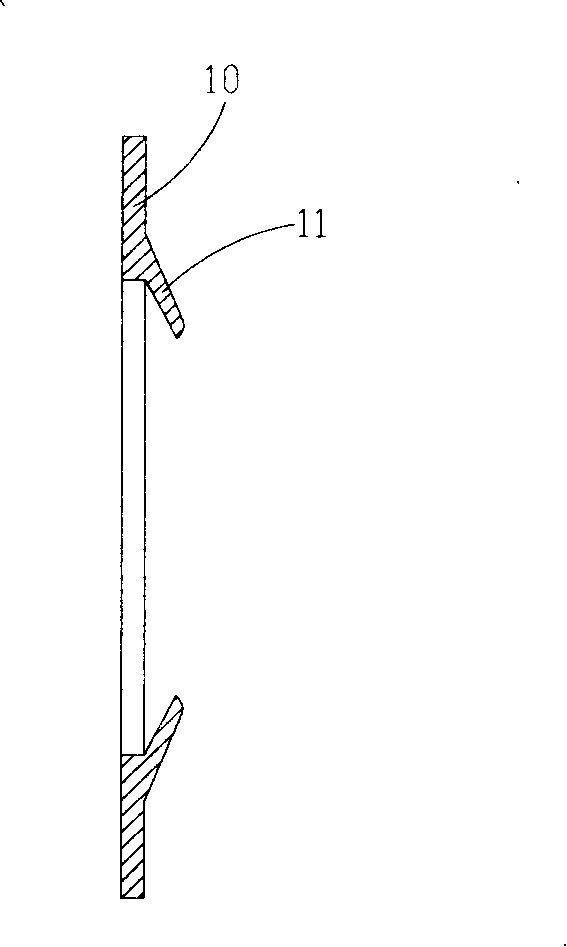

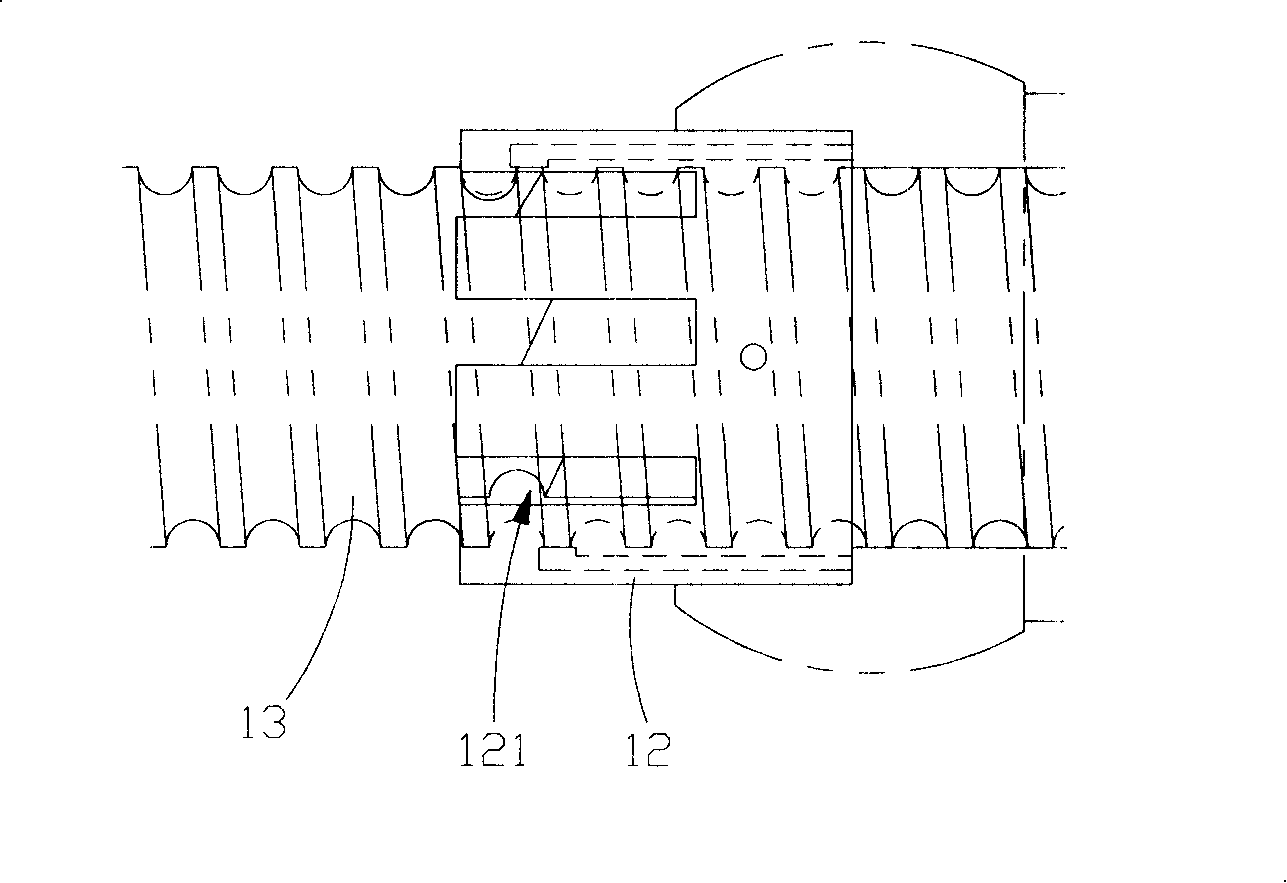

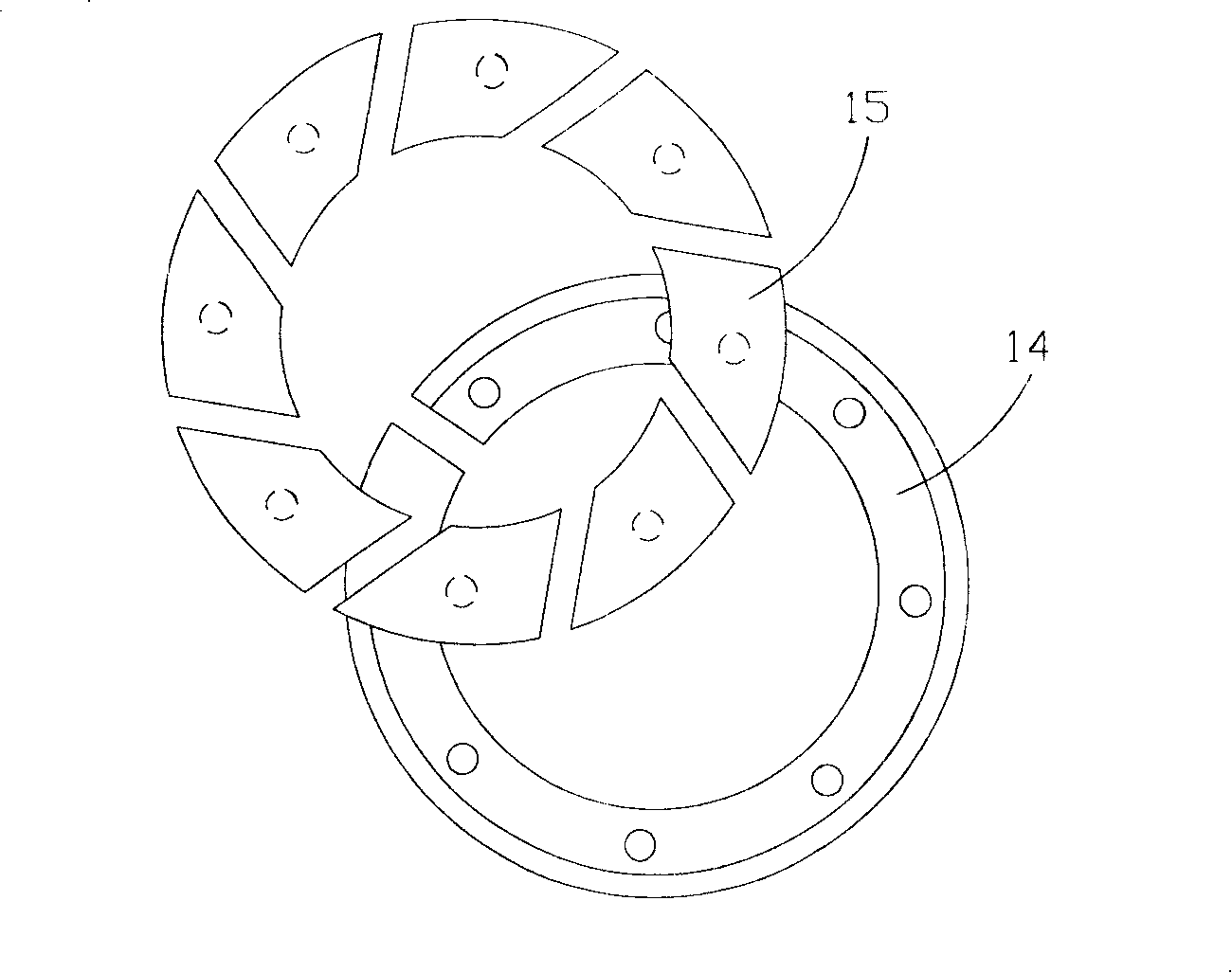

[0025] Please refer to the first embodiment of the present invention Figure 5 to Figure 7 , the ball screw dustproof device of the present invention is assembled on a receiving groove 21 on the end surface of the nut 20, and includes an absorber 30, an oil wiper 40, a wiper 50 and a cover plate 60 at a time from the inside to the outside; Its structural features are:

[0026] The absorber 30 is made of a liquid-absorbable material, such as non-woven fabric, sponge, felt or porous plastic. An absorbing hole 301 for the screw to pass is provided in the middle of the absorber 30, and the absorber 30 is formed by a convex Part 31 is in contact with the surface of the screw, and the absorption volume 301 is the same as or slightly smaller than the cross section of the screw;

[0027] The oil scraper 40 is made of rubber and is assembled on the outside of the absorber 30. There is an oil scraper hole 401 for the screw to pass through in the middle of the oil scraper 40. The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com