Rock high pressure infiltration experiment system

A test system, high-pressure technology, applied in permeability/surface area analysis, soil material testing, material inspection products, etc., can solve the problems of pipeline leakage, affecting test results, low accuracy of differential pressure sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

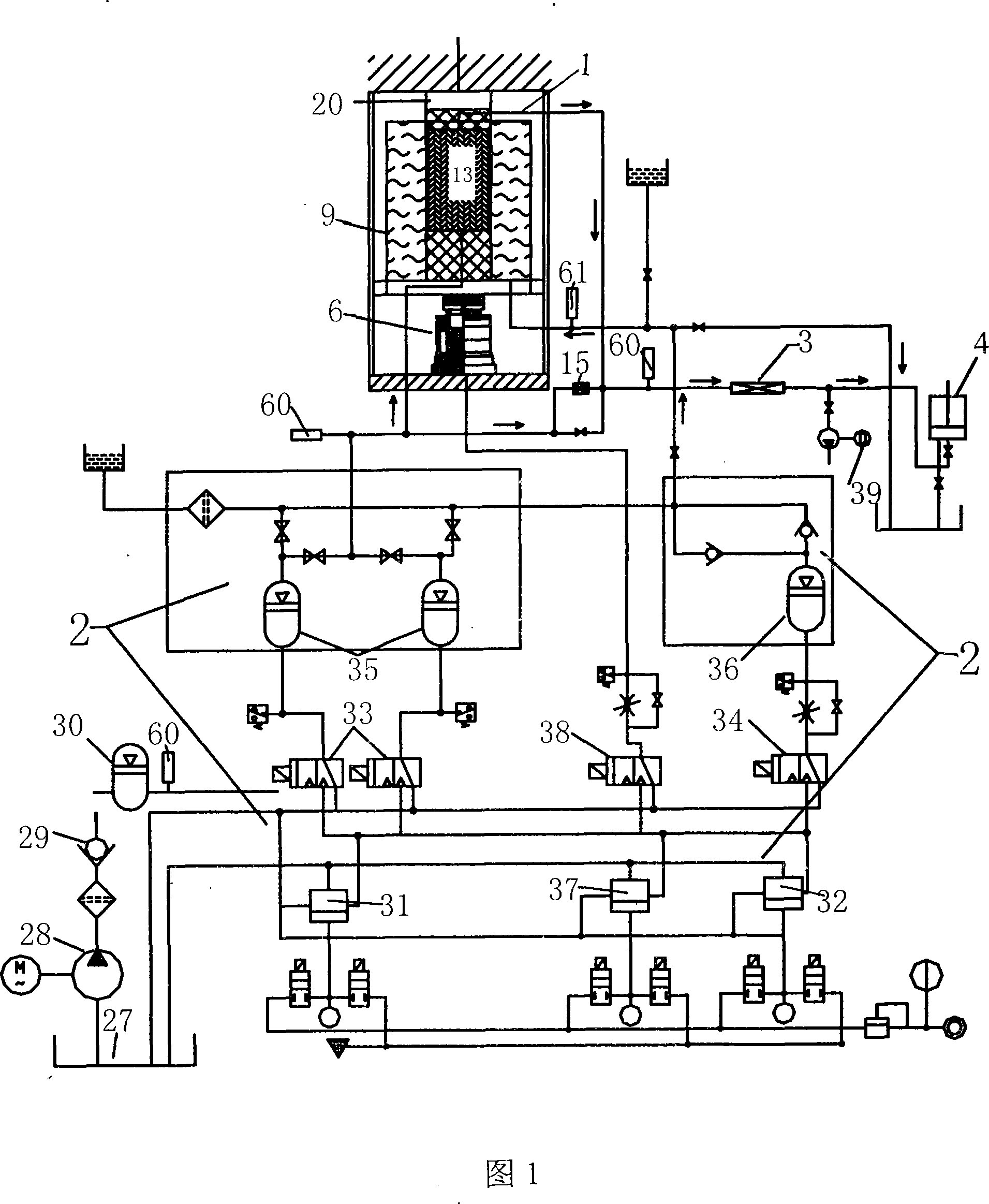

[0034] Referring to FIG. 1 , the high-pressure rock penetration test system of the present invention includes a sample pressure chamber device 1 , an oil-water conversion power control system 2 , a water flow control system 3 at the water outlet, and a volume change measuring instrument 4 .

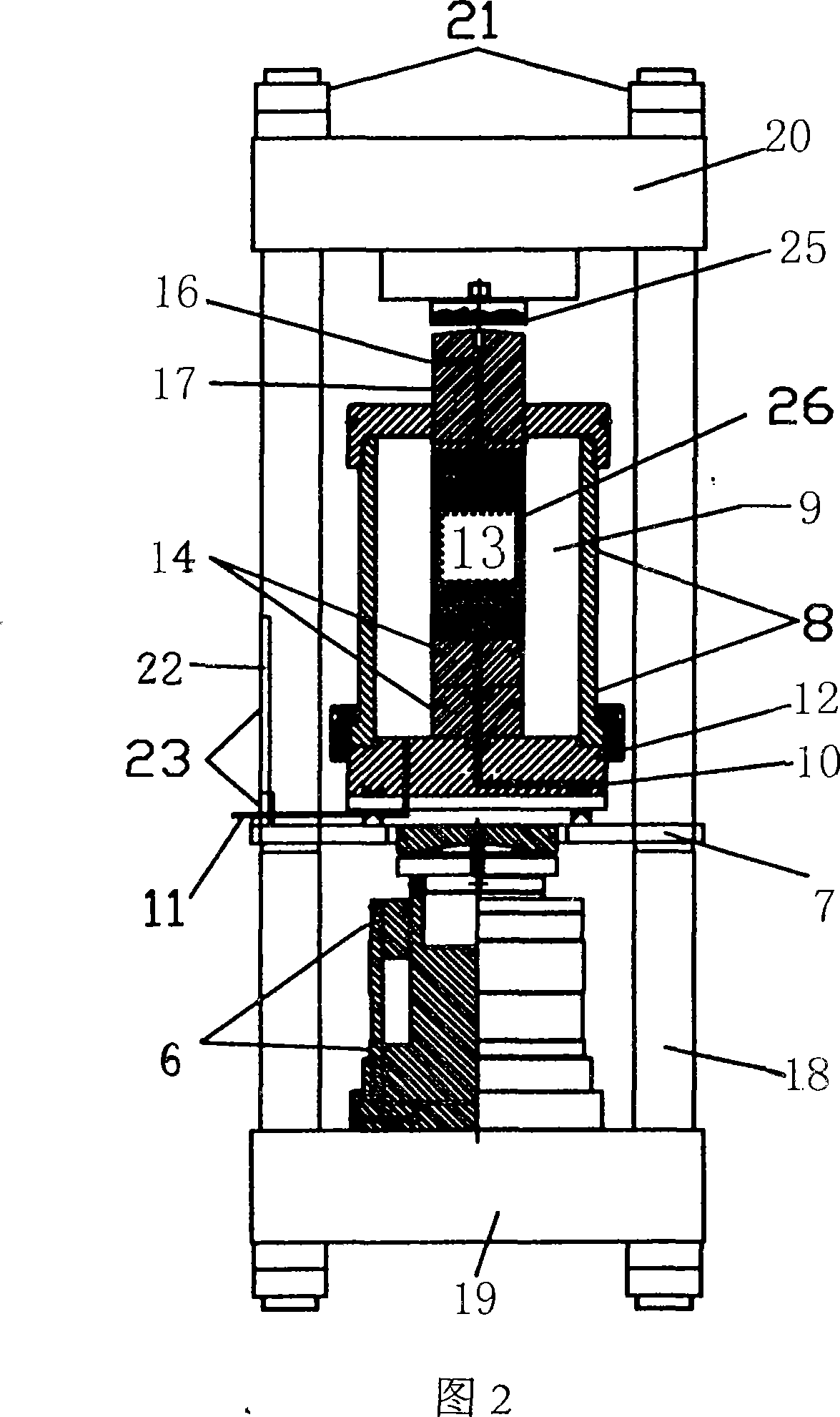

[0035] Referring to Fig. 2, the sample pressure chamber device has a load-bearing frame 5, a hydraulic jack 6 located in the load-bearing frame, a mobile trolley 7 placed on the top of the hydraulic jack, and a triaxial pressure chamber 8 fixed on the mobile trolley. The triaxial pressure chamber includes a confining pressure chamber 9, a pressure chamber base 12 with a permeate water inlet 10 and a confining pressure water inlet 11 communicating with the confining pressure chamber, located on the base of the pressure chamber connected to the permeate water inlet and the sample 13 The downward force column system 14 connected with the permeable water channel of the sample is located at the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com