Layer-twisted type optical-cable

A layered, optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of increasing the diameter of the optical cable, increasing the cost, and poor strength of the loose tube, and achieving weight reduction, cost saving, strong lateral pressure resistance and load-bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

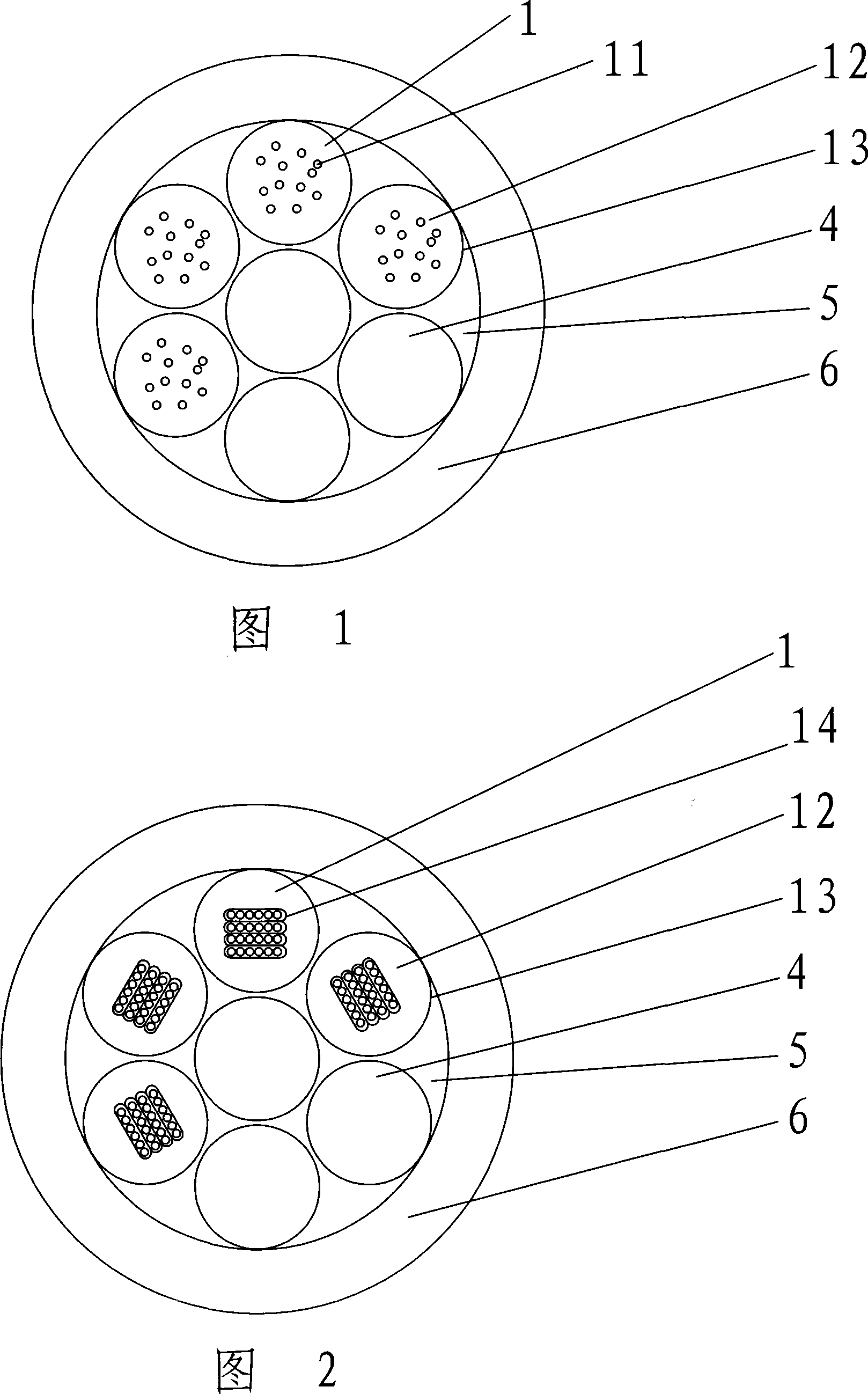

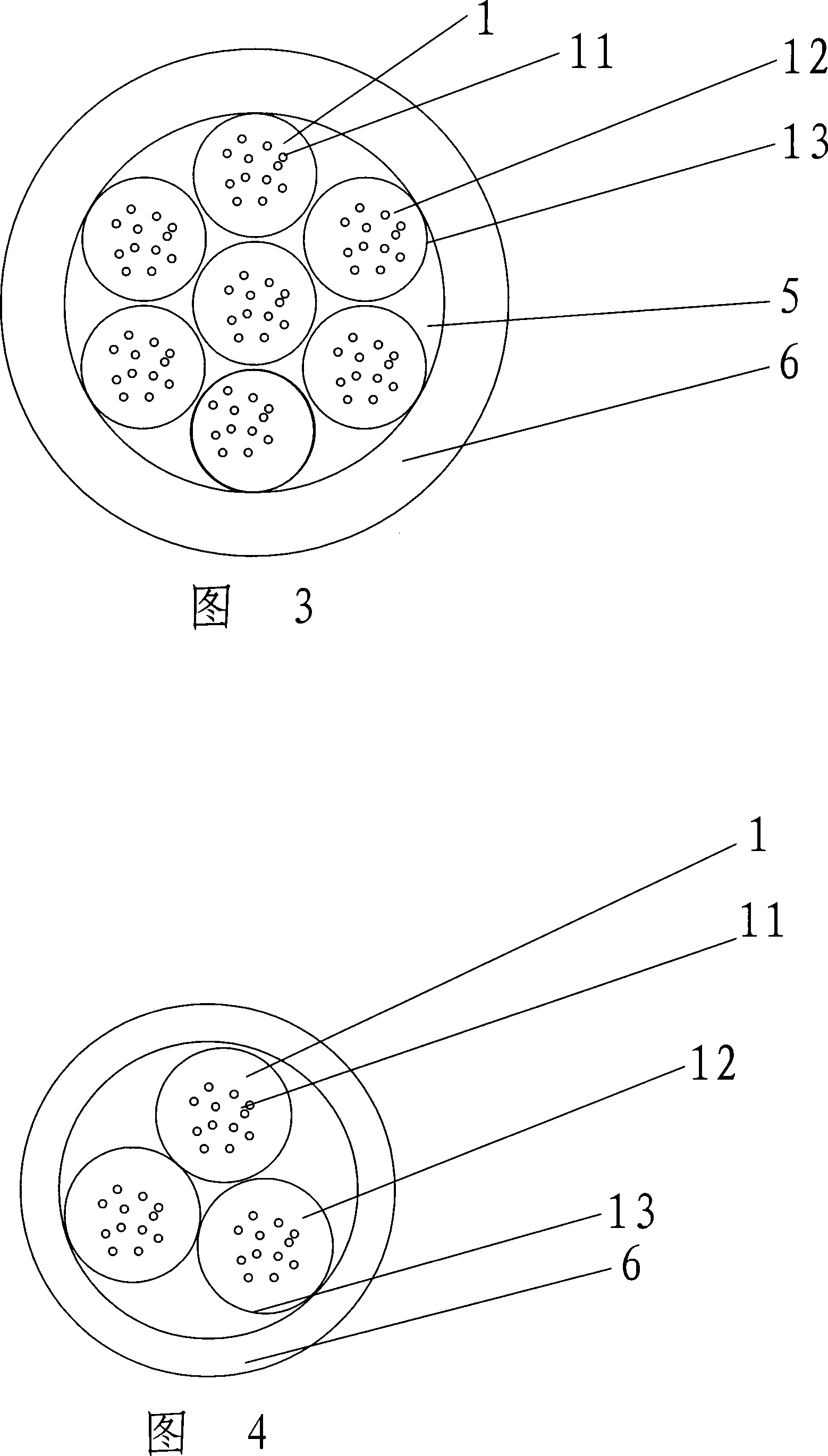

[0023] Fig. 1 is a cross-sectional view of Embodiment 1 of the present invention, as shown in the figure, the outside of the optical cable is a sheath 6, where the sheath 6 of the optical cable is made of polyethylene or other materials, and its main function is to wrap the cable core inside, The cable core is formed by twisting four optical cable core wires 1 and two steel wires 4 around a steel wire in the center. According to requirements, the number of optical cable core wires and steel wires in the cable core can be different. The optical cable core wire 1 is composed of a sleeve 13 made of a plurality of optical fibers 11 and a stainless steel tube for protecting the optical fiber. The diameter of the standard optical fiber is only a few hundred microns, so multiple optical fibers can be placed in one stainless steel tube. , fiber grease 12 is also filled between the gaps of the optical fibers in each stainless steel tube in order to better protect the optical fibers. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com