Tray cleaning technique for computer hard disk fittings

A technology for computer hard disks and trays is applied in the field of tray cleaning technology for computer hard disk accessories, which can solve the problems that the cleanliness cannot meet the requirements of hard disks and semiconductors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

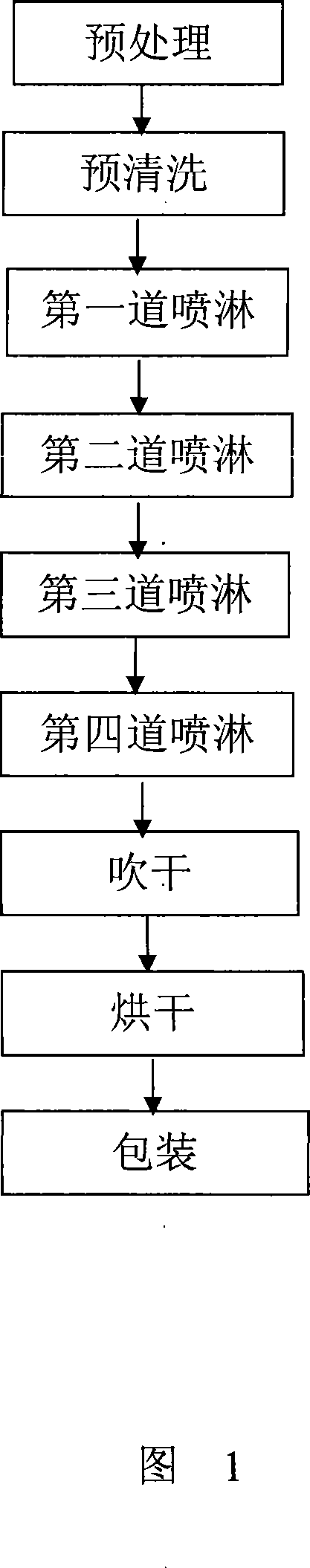

[0022] An ultra-clean tray for storing spare parts used in a clean room environment. Its cleaning process is as follows:

[0023] a. Manually pre-treat the tray to remove labels and other visible foreign matter on the surface.

[0024] b. Before entering the 1000-class clean room, first pass through the cargo shower. The function of the cargo shower is: the efficiency of the tray is 99.99%, the filter particles are > 0.3um, and the large particles on the surface are removed, thereby reducing the pollution to the 1000 class.

[0025] c. Employees in dust-free suits transport the pallets to the 1000-level environment. Class 1000 means that the number of particles with a size above 0.5mm (including 0.5mm) does not exceed 1000 per cubic foot of space.

[0026] d. The operator first puts the tray in the special fixture for the tray, and then puts it on the automatic cleaning machine. The system will automatically run according to the process.

[0027] e. The system first pre-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com