Method for preparing aluminum oxide from coal series kaolinite rock or coal gangue

A technology of kaolinite and coal gangue, which is applied in the field of high-value comprehensive utilization of coal-measure kaolinite or coal gangue resources, can solve the problems of high leaching temperature, high calcination temperature, and long leaching time, and achieve energy saving and resources, mild operating conditions, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

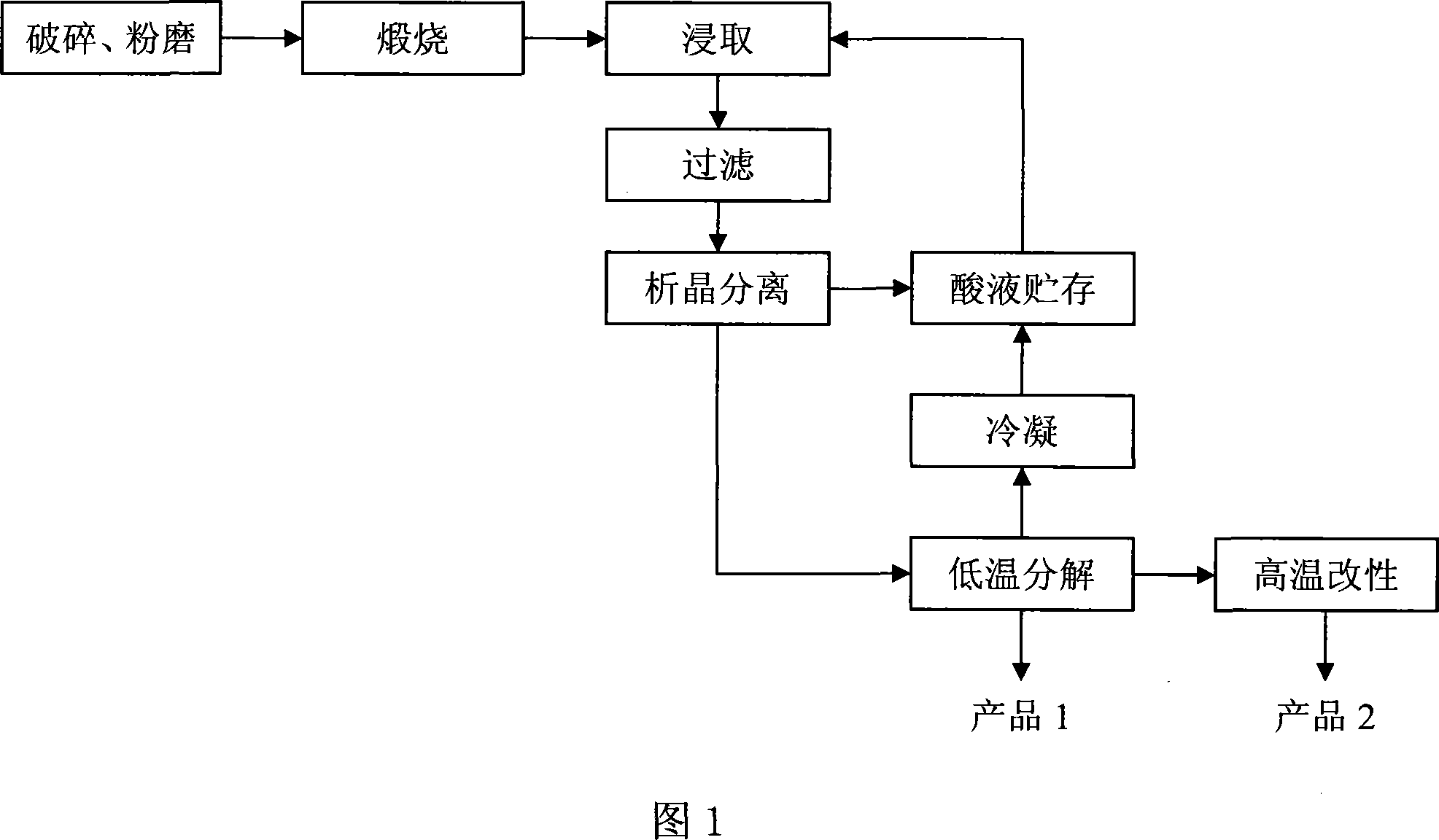

Image

Examples

Embodiment 1

[0023] The coal gangue with a mass percentage of carbon of 20% and a mass percentage of alumina of 33.18% was crushed and ground to a size less than 120 μm, calcined at 550°C for 60 minutes, and 25% of Hydrochloric acid, leached at 100°C for 60 minutes, the leaching rate of alumina was 87.45%, and the aluminum chloride solution was obtained by filtration and separation. Aluminum chloride is directly decomposed at 250°C to produce fine powder alumina, which is preheated and then modified at 1200°C to obtain sandy alumina.

Embodiment 2

[0025] The coal gangue with a mass percentage of carbon of 20% and a mass percentage of alumina of 33.18% is crushed and ground until all of them are smaller than 75 μm. Calcined at 700°C for 10 minutes, added hydrochloric acid with a concentration of 15% according to the solid-to-liquid mass ratio of 1:10, leached at 60°C for 30 minutes, the leaching rate of alumina was 92.71%, and the aluminum chloride solution was obtained by filtration and separation. 0.1MPa, under the condition of 0°C, the precipitant is passed through for 60 minutes, and the hydrous aluminum chloride obtained by crystallization and separation is directly decomposed at 150°C to obtain fine powder alumina, which is preheated and subjected to 1000 ℃ modified to get sandy alumina.

Embodiment 3

[0027] Crush and grind coal gangue with a mass percentage of carbon of 20% and a mass percentage of alumina of 33.18% until it is less than 75 μm in size, and calcined at 600°C for 30 minutes, and the leaching rate of alumina is 91.30%. : 8 Add the hydrochloric acid of concentration 20%, leaching at 95 ℃ for 30 minutes, filter and separate to obtain the aluminum chloride solution, the filtrate is passed through the precipitant at 0.1MPa, 0 ℃ and kept for 60 minutes, and the obtained water-containing Aluminum chloride is directly decomposed at 250°C to produce fine powder alumina, which is preheated and then modified at 1200°C to obtain sandy alumina.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com