Waste aluminum recovery system

A technology of aluminum recycling and aluminum liquid, which is applied in the field of scrap metal smelting and recycling devices, can solve the problems of low output, low yield rate, and large waste, and achieve the effects of increased output, low cost, and reduced oxidation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

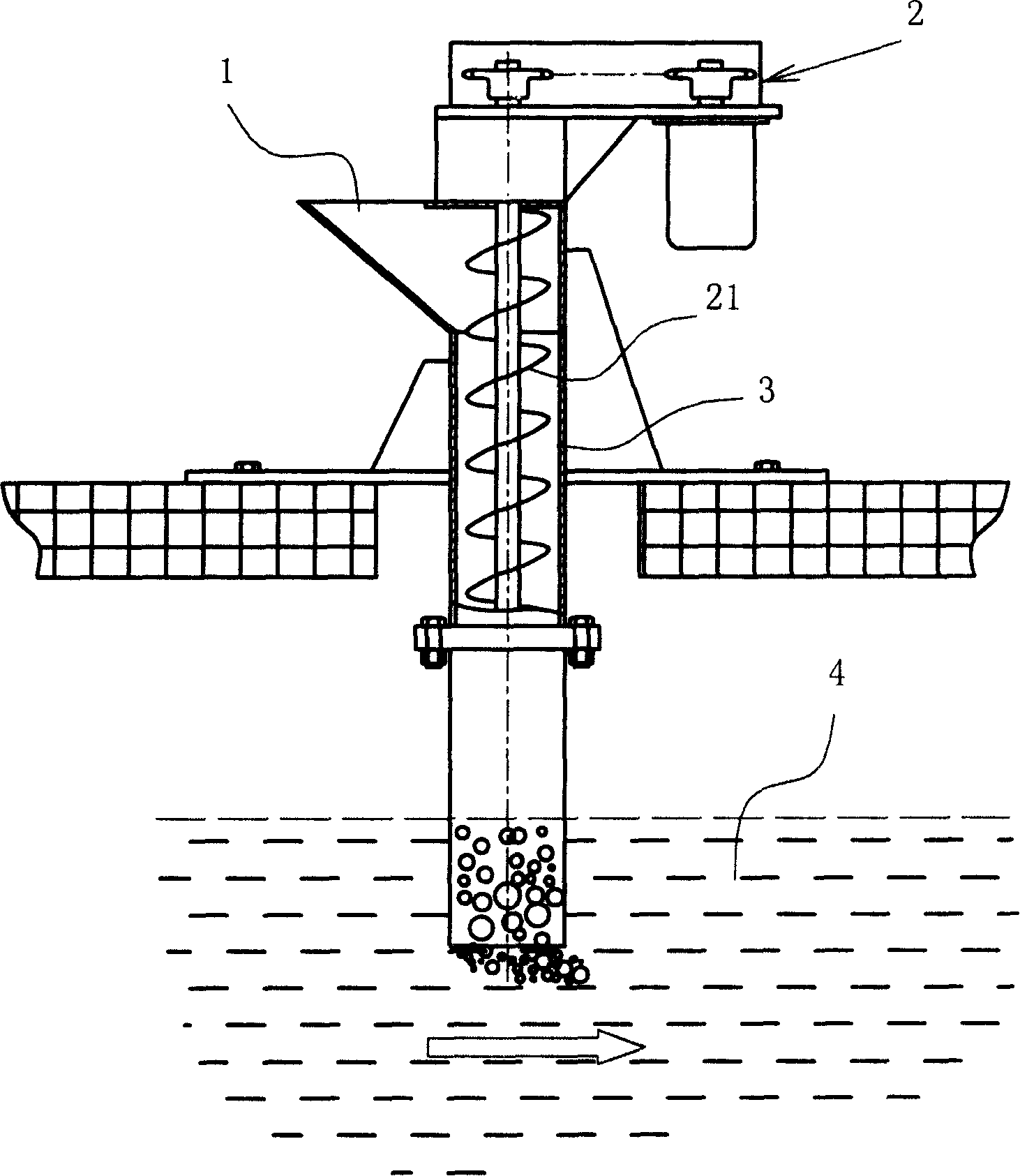

[0029] In the scrap aluminum recovery system, a feeding pipe 3 is set at the feeding place of the smelting furnace, the lower end of which is inserted into the molten aluminum 4, the upper end of the feeding pipe is provided with a feeding port 1, and the feeding pipe 3 is provided with a longitudinal spiral blade 21, which is the The established screw feeder 2 is a part, the screw feeder 2 has a motor, a rotating transmission belt and a rotating output wheel, and the rotating output wheel is associated with the screw blade 21 rotating shafts.

[0030] Aluminum chips are fed from the feeding port 1, and the screw blade 21 rotated by the screw feeder 2 presses the aluminum chips to the lower end of the delivery pipe 3, and is extruded from the lower end into the aluminum liquid layer, and is taken away by the flowing high-temperature aluminum liquid. Melts without exposure to air.

Embodiment 2

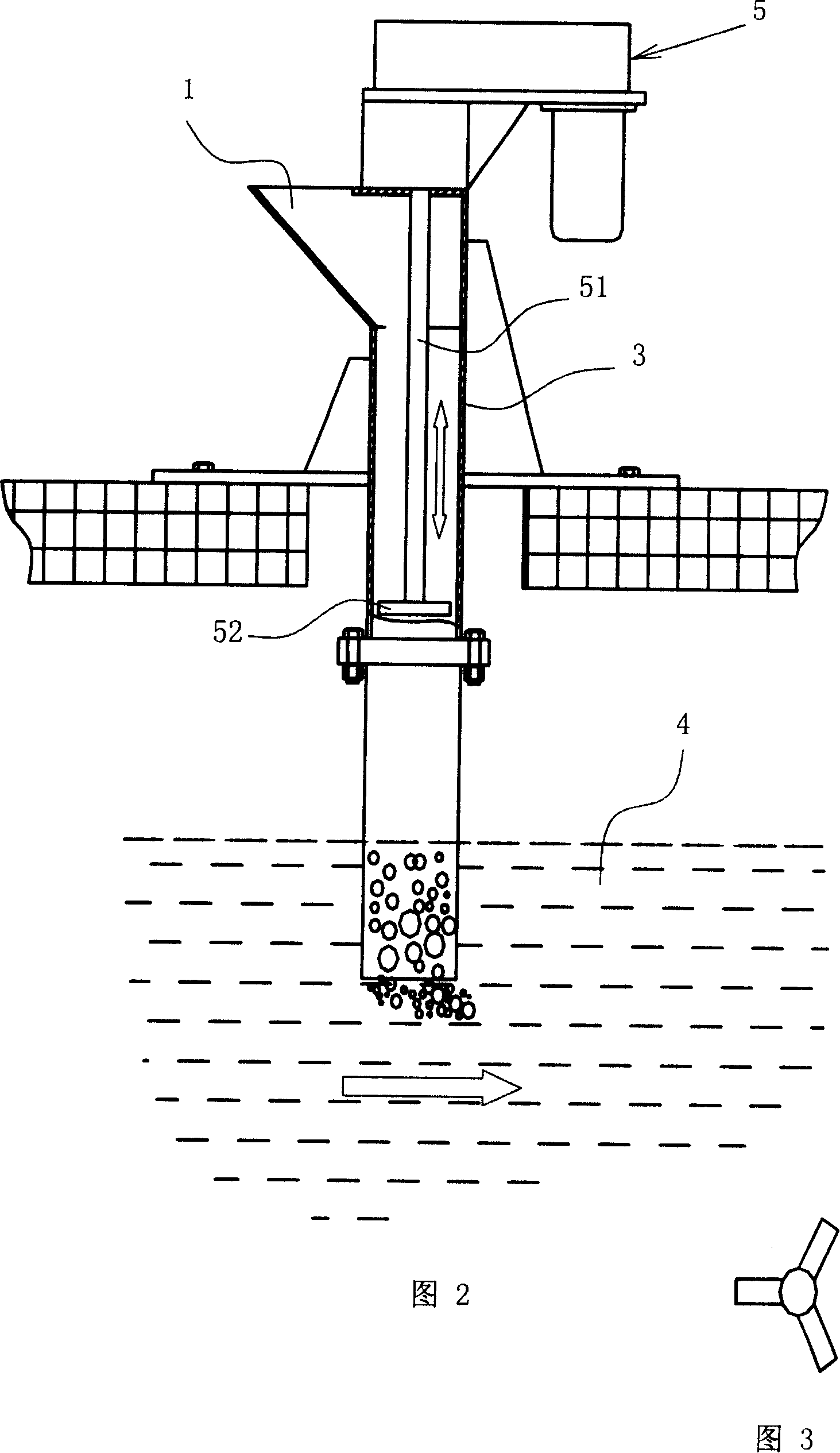

[0032] In this example waste aluminum recovery system, a push rod 51 is provided in the feeding pipe as a part of the set push feeder 5, and the lower end of the push rod is connected with a multi-claw push plate 52, and the push feeder 5 has a motor, a cam, The connecting rod combination device can drive the push rod 51 to move up and down.

Embodiment 3

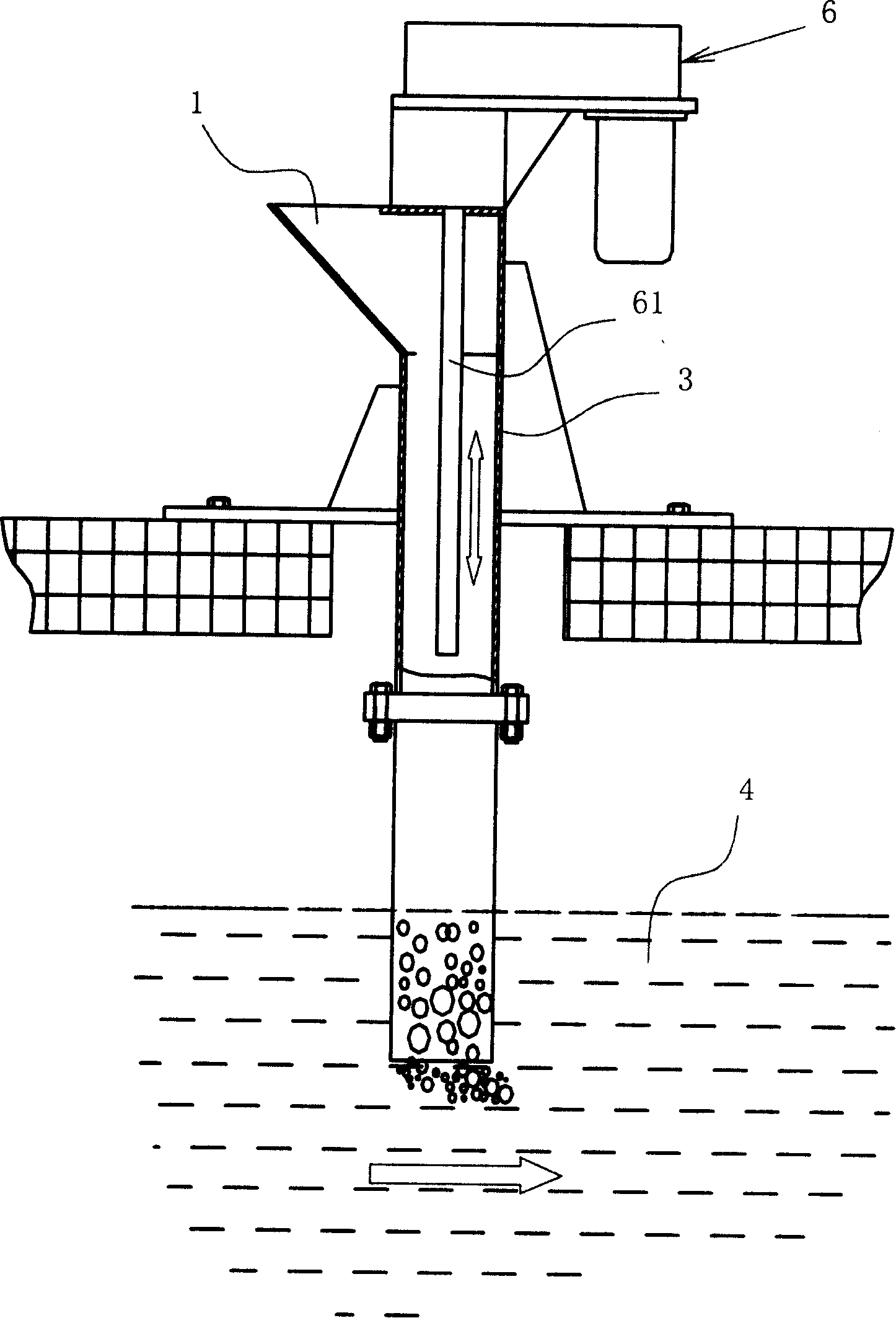

[0034] In this example waste aluminum recovery system, a vibrating rod 61 is provided in the delivery pipe as a part of the vibrating feeder 5, and the vibrating feeder has a vibrating motor, which can drive the vibrating rod 61 to vibrate, so that the aluminum chips are sent under the vibration condition with gravity .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com