Manufacturing device for liquid crystal display panel and manufacturing method of the same

A technology for liquid crystal panels and manufacturing devices, applied in lighting devices, lamp circuit layout, optics, etc., can solve problems such as the influence of liquid crystal panel performance and yield, and the reduction of liquid crystal panel performance and yield, etc., to achieve high-performance yield, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described below with reference to the drawings. In the following description of the drawings, the same or similar parts are given the same or similar symbols. The embodiment shown below is to illustrate the device and method that make the technical idea of the present invention concrete, but the technical idea of the present invention is not limited to the structure and configuration of the specific structural parts given in the following description Wait.

[0053] -Substrate to be processed-

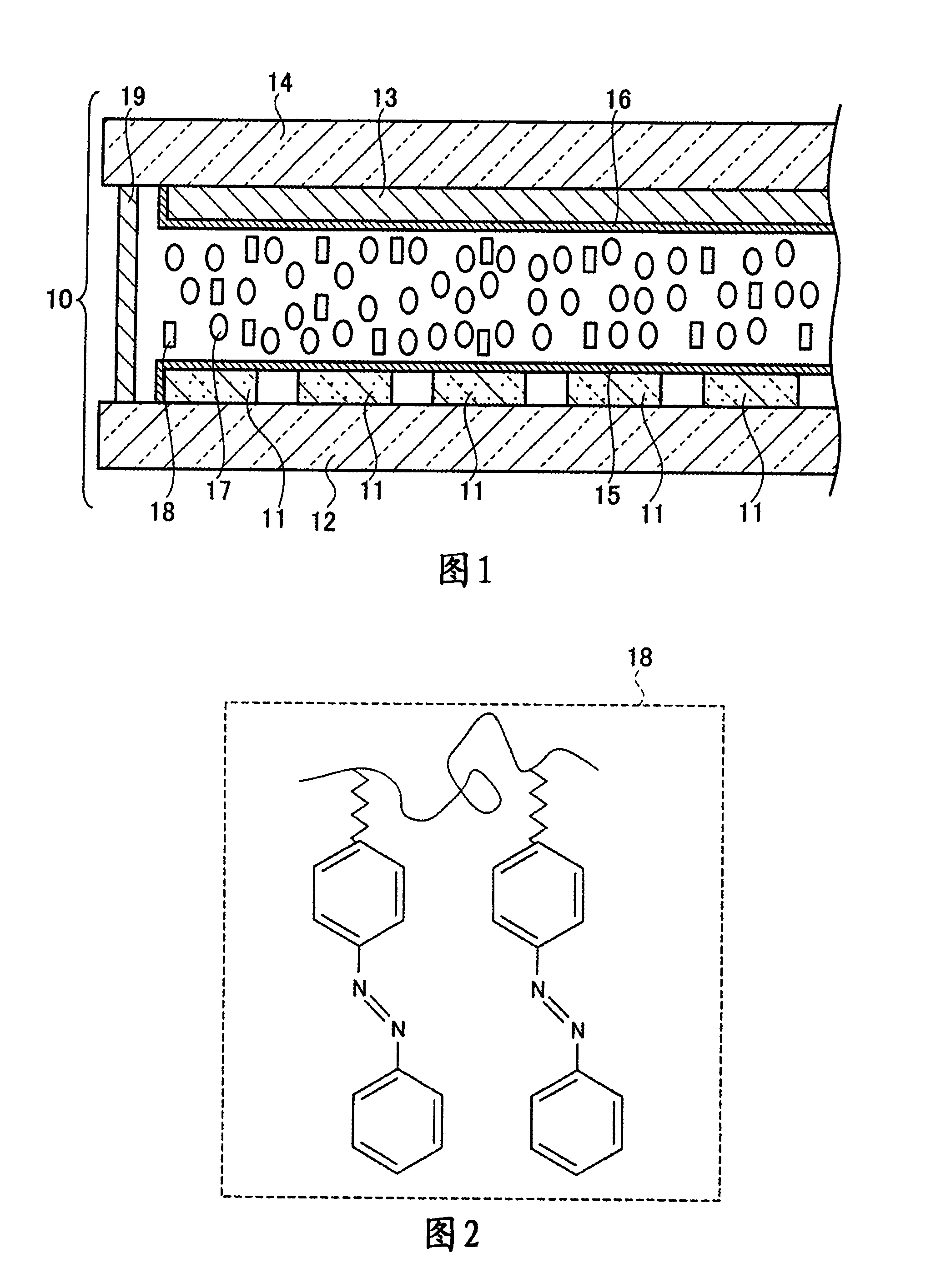

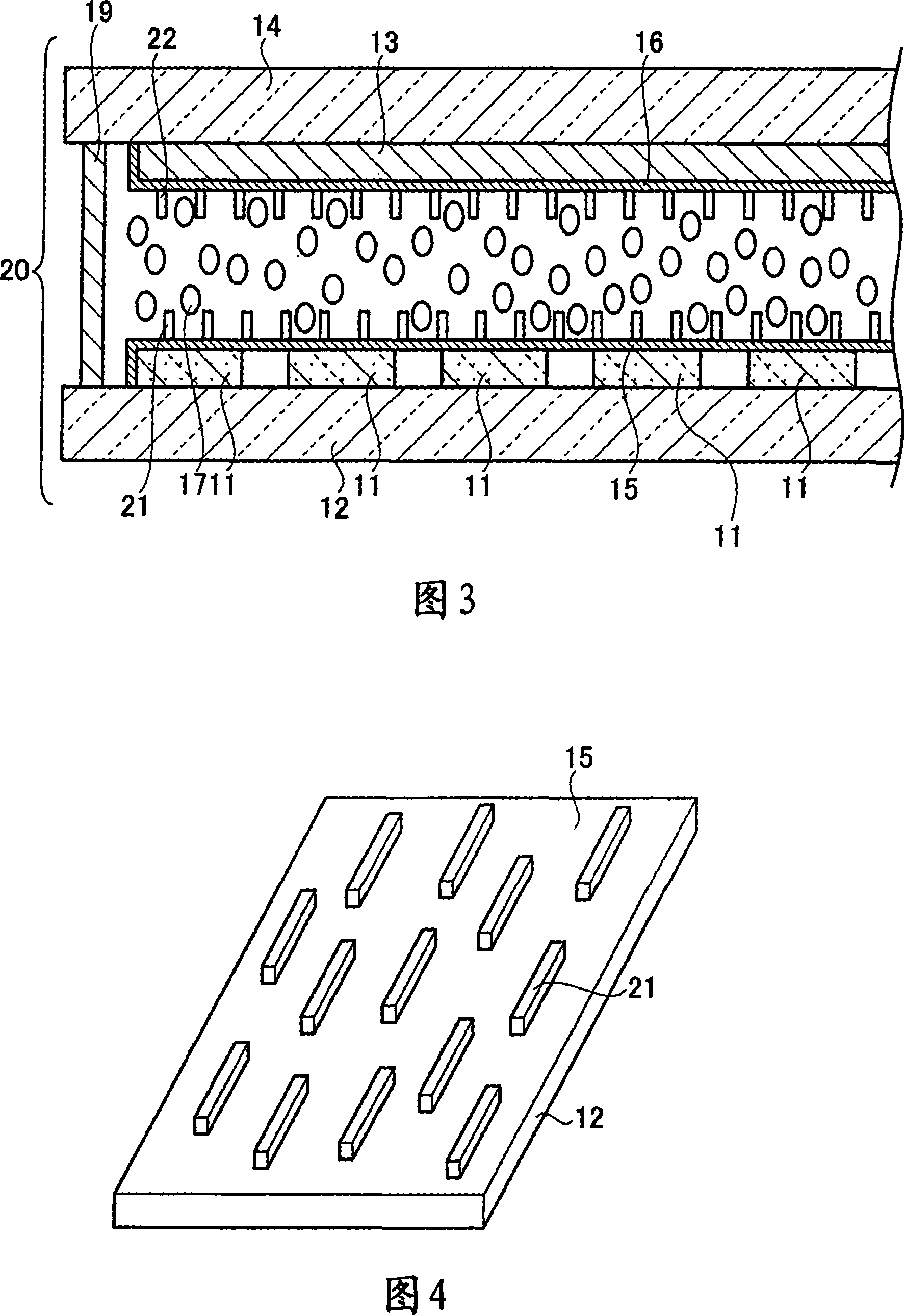

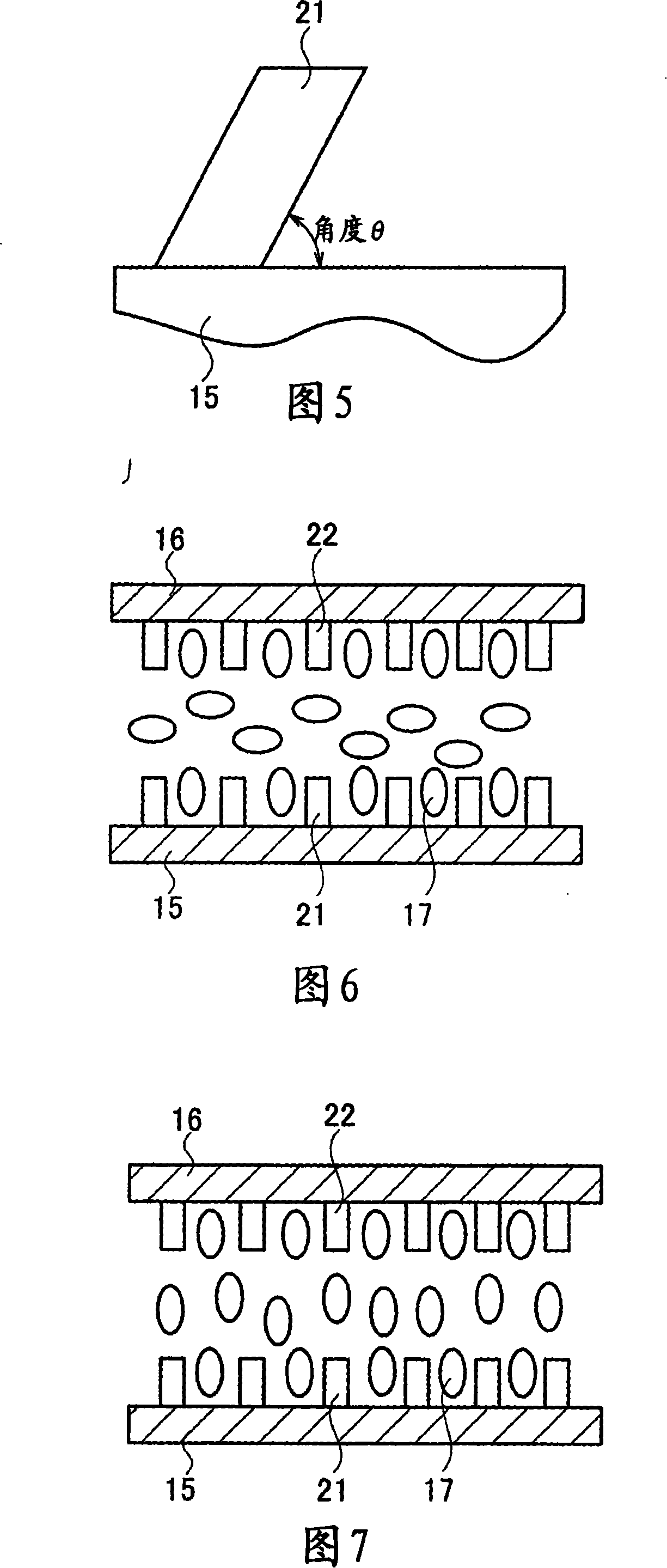

[0054] Next, the substrate 10 to be processed that can be processed by the liquid crystal panel manufacturing apparatus according to the embodiment of the present invention will be described. As illustrated in FIG. 1 , the substrate 10 to be processed is sealed between a first substrate 12 and a second substrate 14 made of glass or the like, and at least a liquid crystal 17 capable of orientation by applying a voltage and a photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com