Body structure of single-phase traction transformer

A traction transformer, single-phase technology, applied in transformers, transformer/inductor magnetic cores, fixed transformers, etc., can solve the problems of insulation strength, overload and short-circuit resistance that are difficult to meet electrified railways, and improve short-circuit resistance. Uniform stress and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

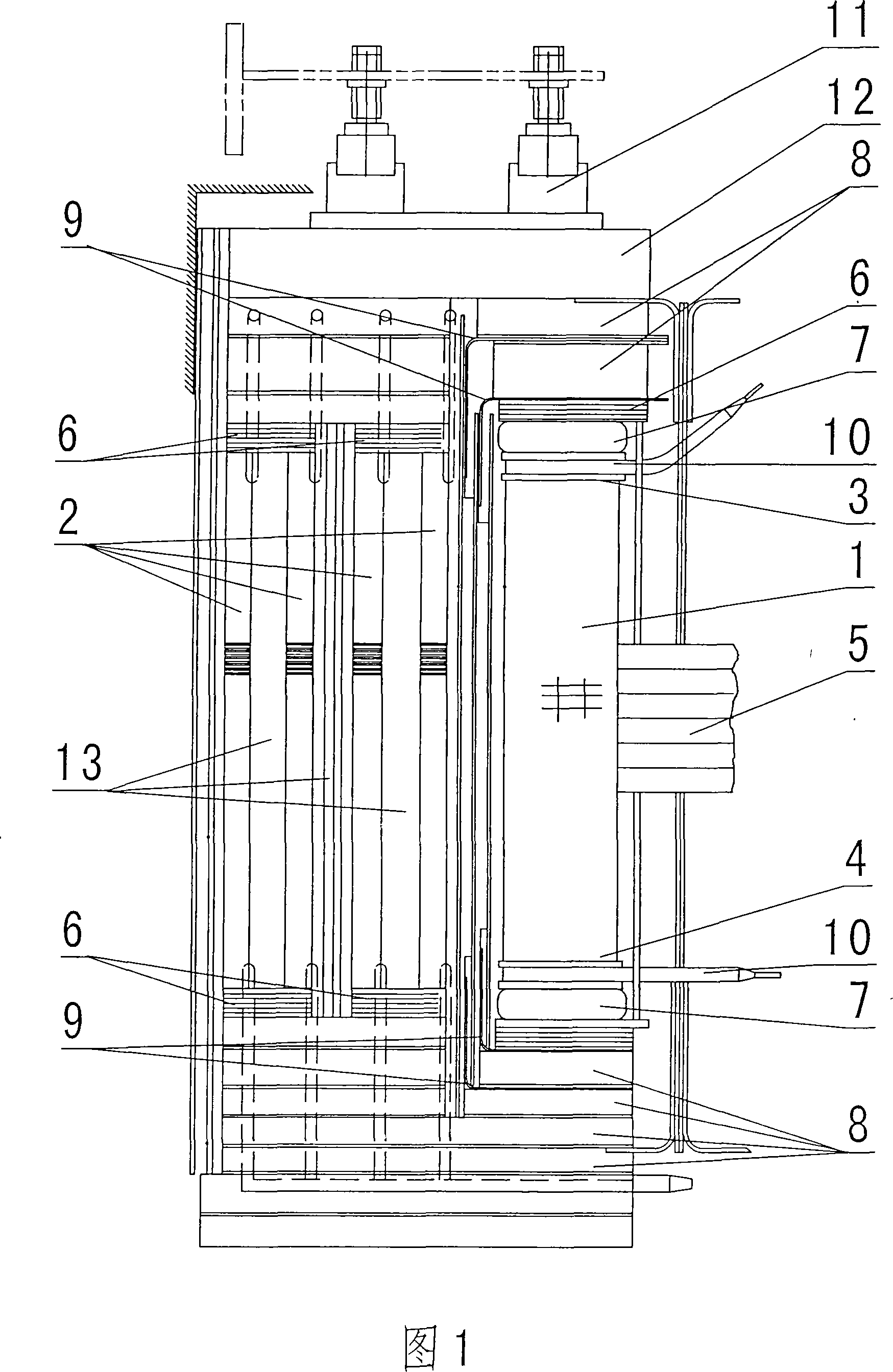

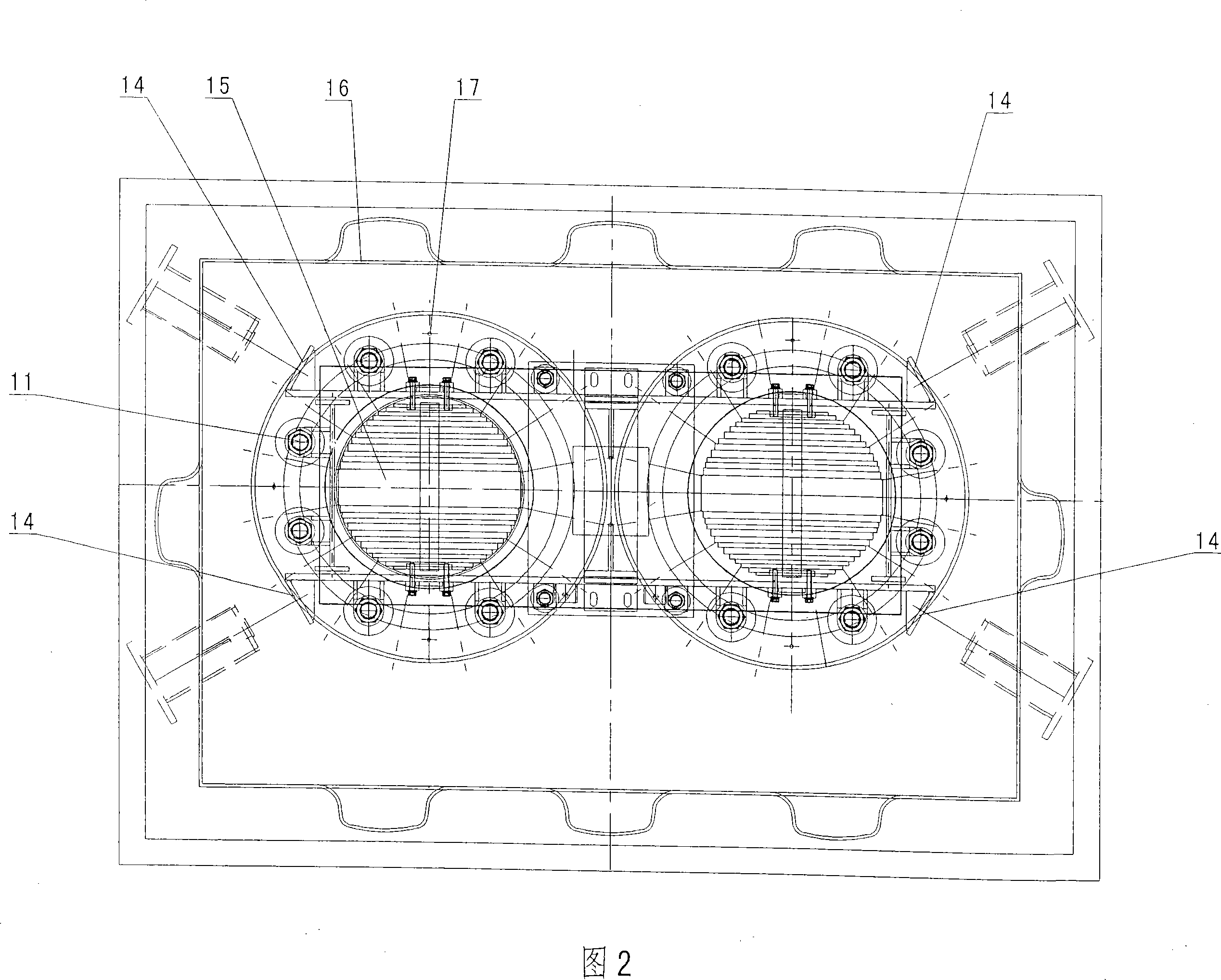

[0015] The present invention mainly consists of core columns 15, high-voltage coils 1 and low-voltage coils 2 placed in series on two core columns 15, etc., and the low-voltage coils are radially split structures, consisting of two or four coils, two or There is a paper tube oil gap insulation structure 13 between the four coils; the head end 3 of the high-voltage coil is an entangled winding structure, and the other line segments are a continuous winding structure. There is an electrostatic ring 7 between them, and two corner rings 9 are arranged symmetrically between the layers of the high-voltage coil head 3 and the end 4 of the high-voltage coil and the iron yoke insulation 8; The pressing plate 12 is pressed and fixed; the four corners of the iron core post 15 and the upper fuel tank 16 can be positioned by the positioning plate 14, and the bottom is positioned by the positioning nail 17.

[0016] The body is fully insulated. The high-voltage coil 1 and the low-voltage c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com