Polyurethane-mixed head with spray Nozzle for a spray head and uses of spray nozzle

A technology of mixing head and polyurethane, which is applied in the direction of spraying device, spraying device, liquid spraying device, etc., and can solve the problem of not being able to use the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

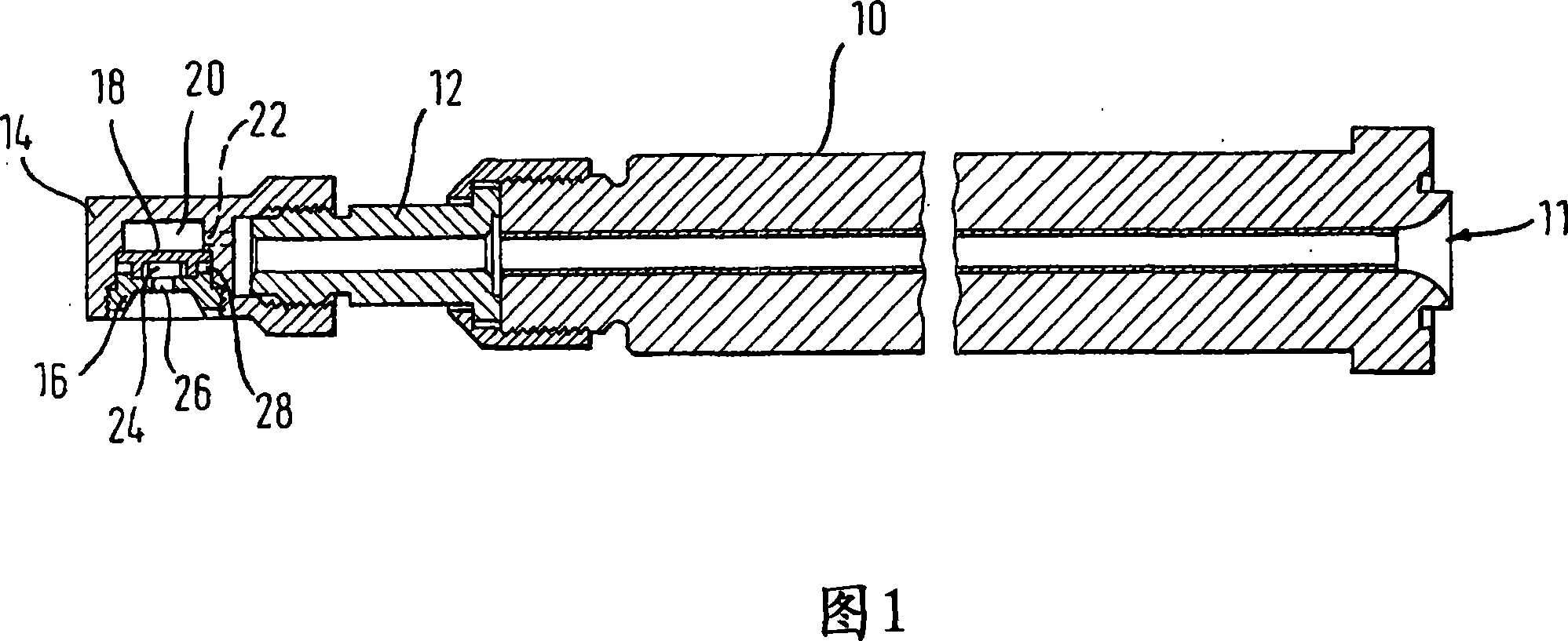

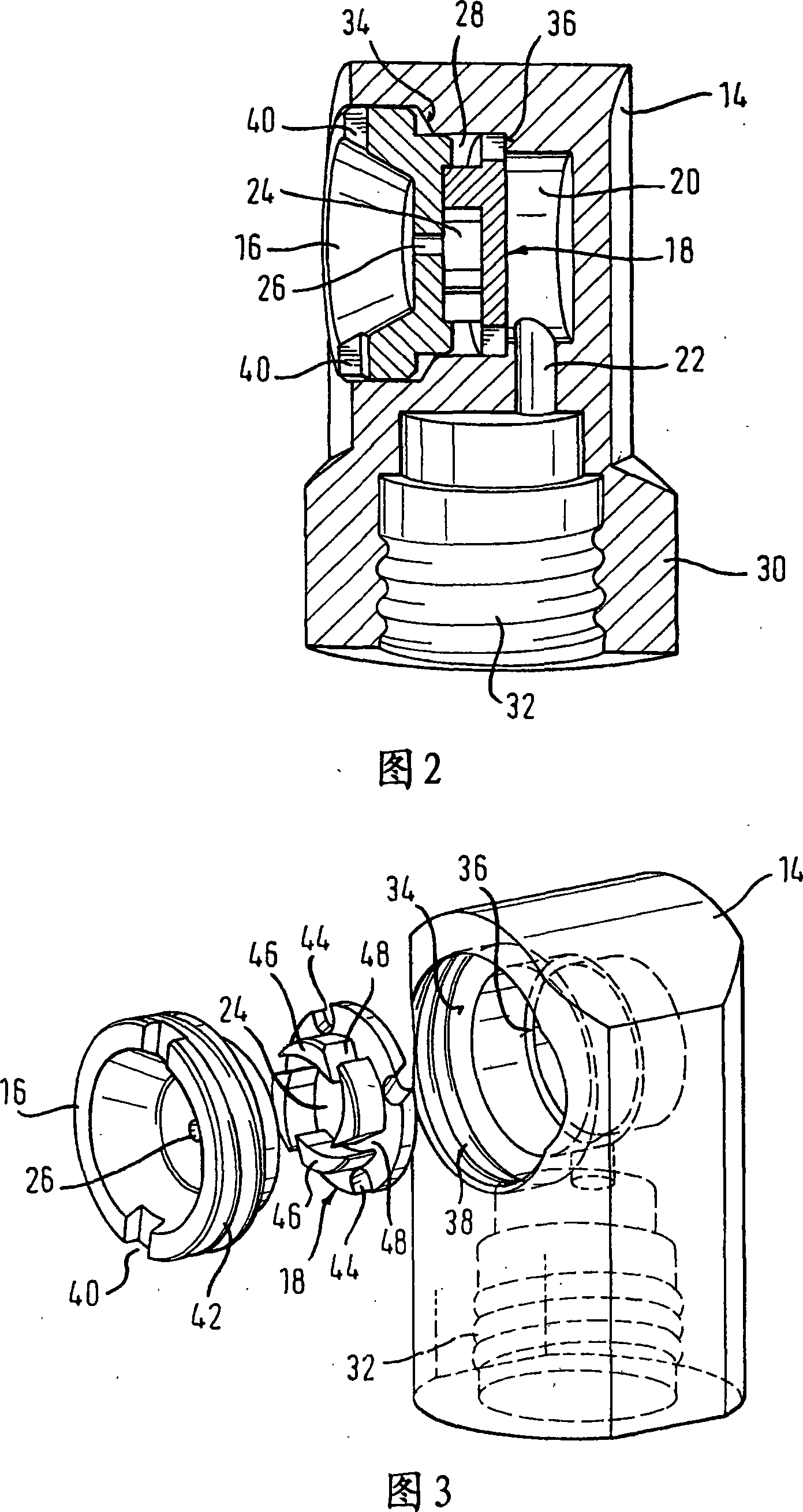

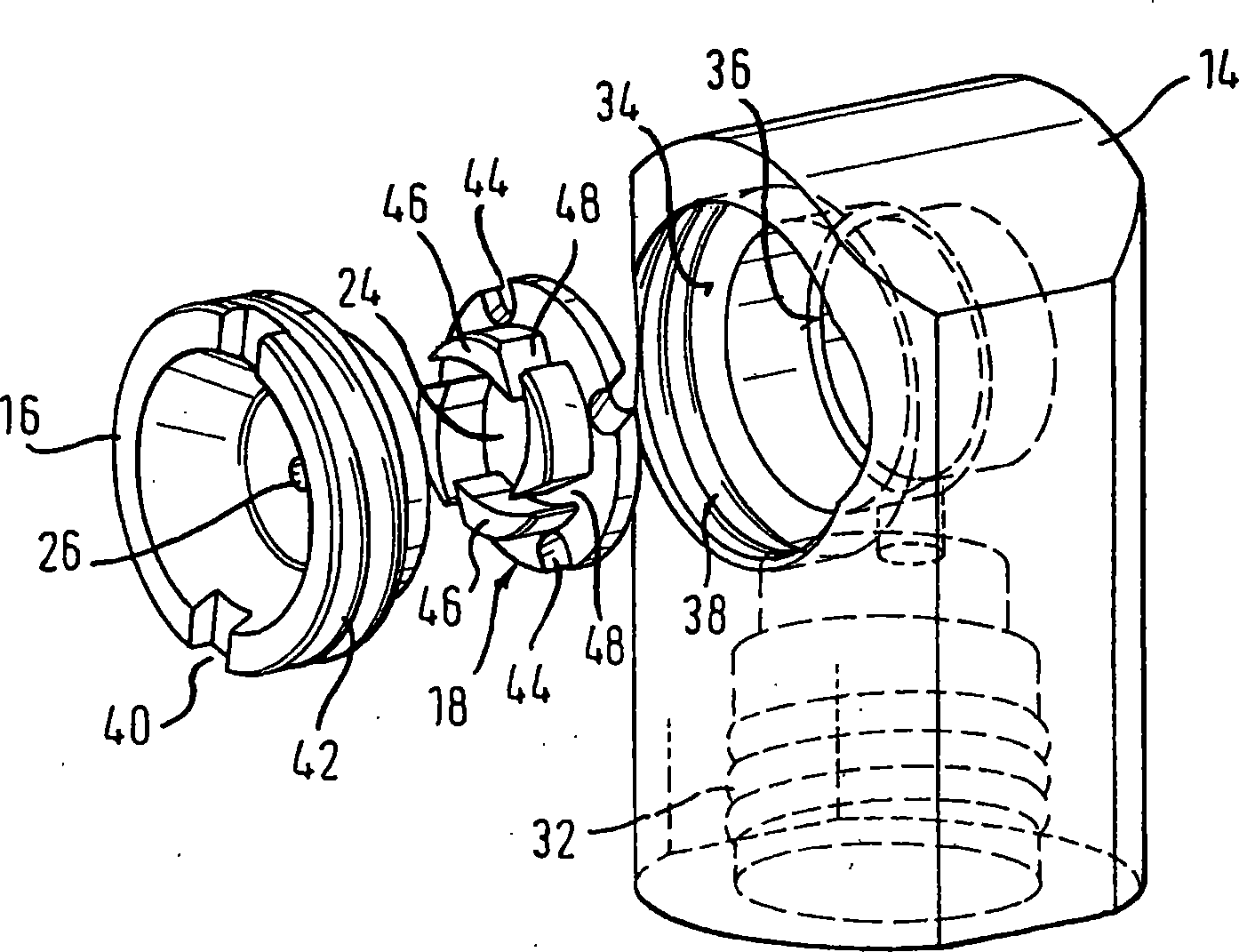

[0031] In the following description only the spray nozzles for the spray heads are shown. Such spray nozzles are attached to a mixing head nozzle 10 which is arranged on a mixing head of a polyurethane plant (not shown). Such a device including such a mixing head is known, for example, from EP 0 389 014 B1. Usually, two reactive raw materials, such as polyol and isocyanate, are fed to such a mixing head. These materials are then mixed with one another in a mixing head and subsequently discharged. The reacted discharge mixture can be applied via spray nozzles to a surface where the mixture reacts thoroughly and forms a plastic surface.

[0032] Depending on the surface structure, this surface layer can be formed as a textured or otherwise structured surface. These skins can be further processed by post-injection or post-foaming, the skins themselves forming the decorative surface.

[0033] In order to form a good quality polyurethane skin, it is necessary to have the expell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com