Ball pen tip and aqueous ball point pen using the same

A ballpoint pen tip, water-based technology, applied in the direction of ballpoint pen, pen tip, lighting device, etc., can solve problems such as inability to obtain, offset of handwriting, and penetration of handwriting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

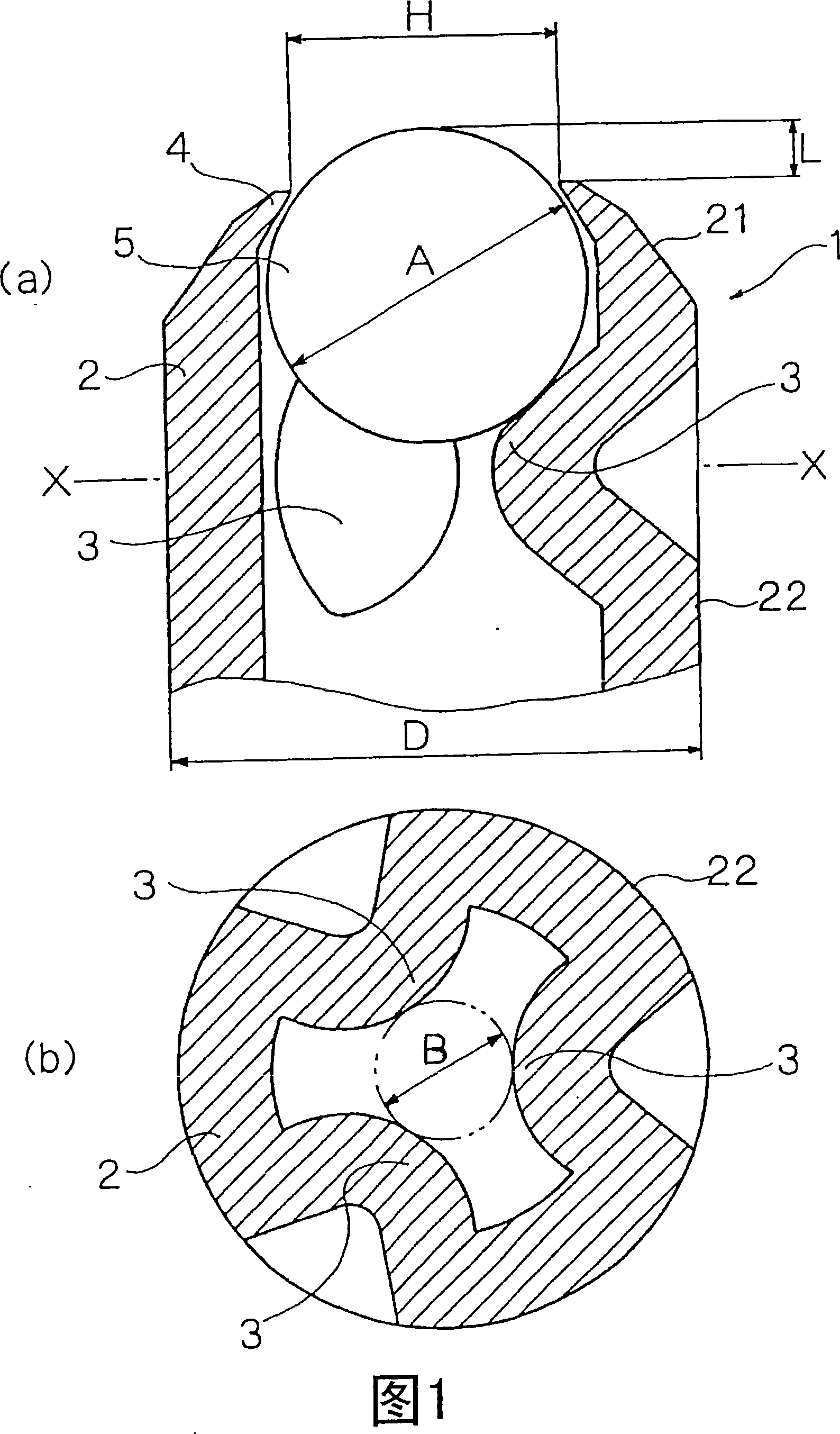

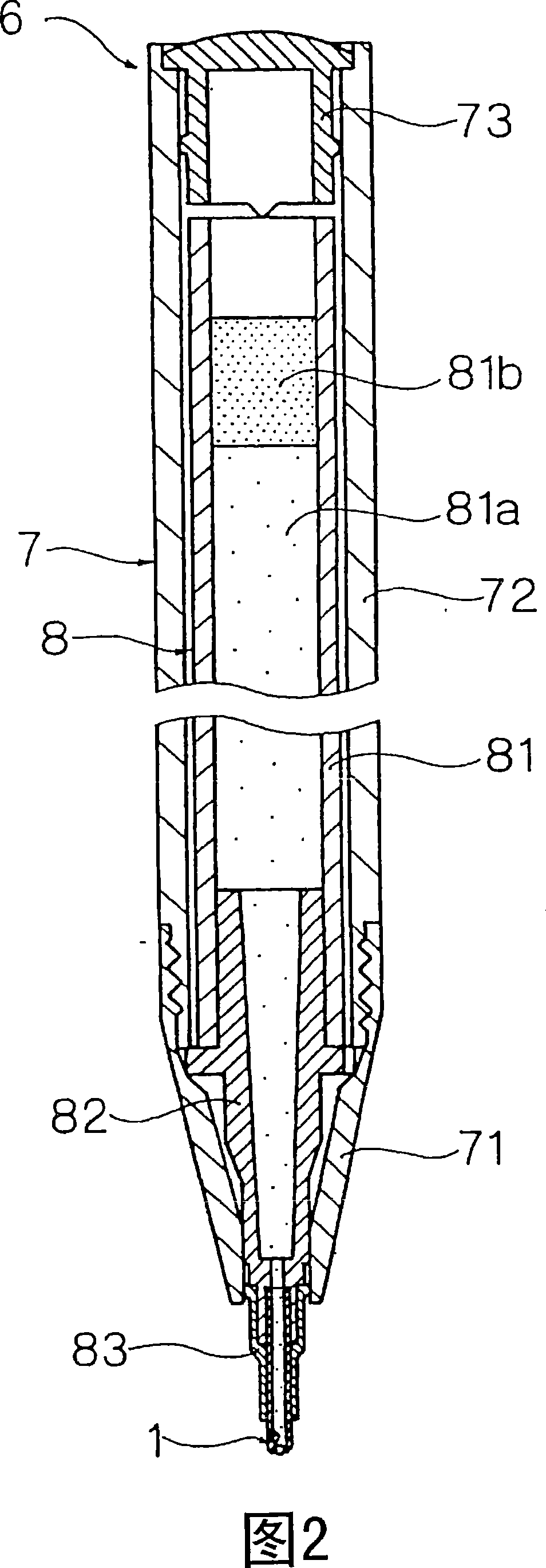

[0144] FIG. 1 shows a first embodiment of a ballpoint pen tip 1 of the present invention. The ballpoint pen tip 1 of this embodiment includes: a straight cylindrical metal body 2 made of SUS321; A (here, 3) internally protruding bead support seat 3; a riveting portion 4 formed by deforming the inside of the front end of the pointed front end portion 21 of the aforementioned metal body 2 into a circumferential shape; rotatably held Hold the bead body 5 between the aforementioned bead body support seat 3 and the aforementioned riveting portion 4 .

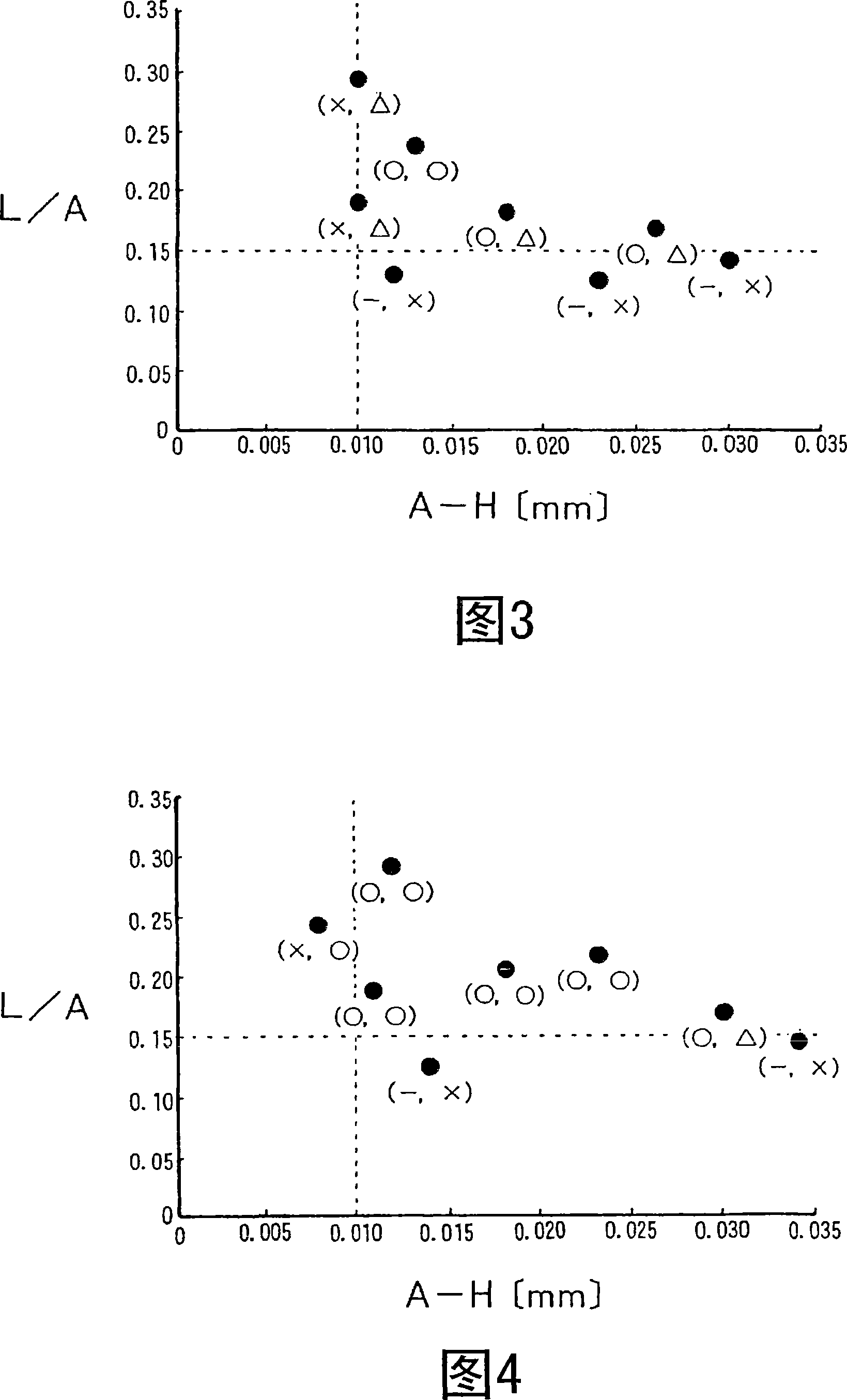

[0145] Two types of outer diameters A of 0.25 mm and 0.28 mm were used for the beads 5 . The metal body 2 forms a straight cylindrical portion 22 with a substantially constant outer diameter from the rear end of the pointed front end portion 21 located in front of the bead holder 3 to the rear end of the metal body 2, and becomes needle-shaped. When the outer diameter A of the aforementioned beads 5 is 0.25 mm, the outer diameter D...

no. 2 Embodiment

[0188] FIG. 6 shows a second embodiment of the ballpoint pen 1 of the present invention. The ballpoint pen tip 1 of this embodiment includes: a cylindrical SUS304 metal main body 2 having a pointed front end portion 21, a bead support seat 3 formed on the inner surface near the front end of the metal main body 2 by cutting, The caulking portion 4 formed by deforming the inside of the tip end portion 21 of the metal body 2 into a circumferential shape, and the bead held between the bead support seat 3 and the caulking portion 4 in a rotatable manner. Body 5.

[0189] The pointed tip portion 21 is formed on the outer surface of the tip portion of the metal main body 2 to extend rearward from the caulking portion 4 over the bead holder 3 . A center hole 31 and a plurality (here, three) of ink induction grooves 32 radially communicating with the center hole 31 are provided through the bead holder 3 in the axial direction. Two types of outer diameters A of 0.25 mm and 0.28 mm wer...

no. 3 Embodiment

[0227] 10 to 12 show a third embodiment of the ballpoint pen tip 1 of the present invention.

[0228] (ballpoint pen tip)

[0229] The ballpoint pen tip 1 of this embodiment includes: a straight cylindrical metal main body 2 made of stainless steel (for example, austenitic stainless steel such as SUS321), and includes a A plurality of (here, three) internally protruding bead support seats 3 formed by pressing deformation (press processing) are formed by internally deforming (riveting deformation) the front end of the pointed front end portion 21 of the aforementioned metal body 2. The riveting portion 4 formed in a circumferential shape, the bead holding hole 23 formed between the bead holder 3 and the riveting portion 4, the bead held in the bead holding hole 23 rotatably Body 5.

[0230] The aforementioned bead body 5 adopts a bead body whose outer diameter A is 0.25 mm. The metal main body 2 is formed with a straight cylindrical portion 22 from the rear end of the pointe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com