Method and device for producing crystal anhydrous lithium chloride

A production method, lithium chloride technology, applied in the direction of lithium halide, etc., can solve the problems of large equipment footprint, poor site environment, cumbersome operation, etc., and achieve the effects of improved production efficiency, reliable product quality, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

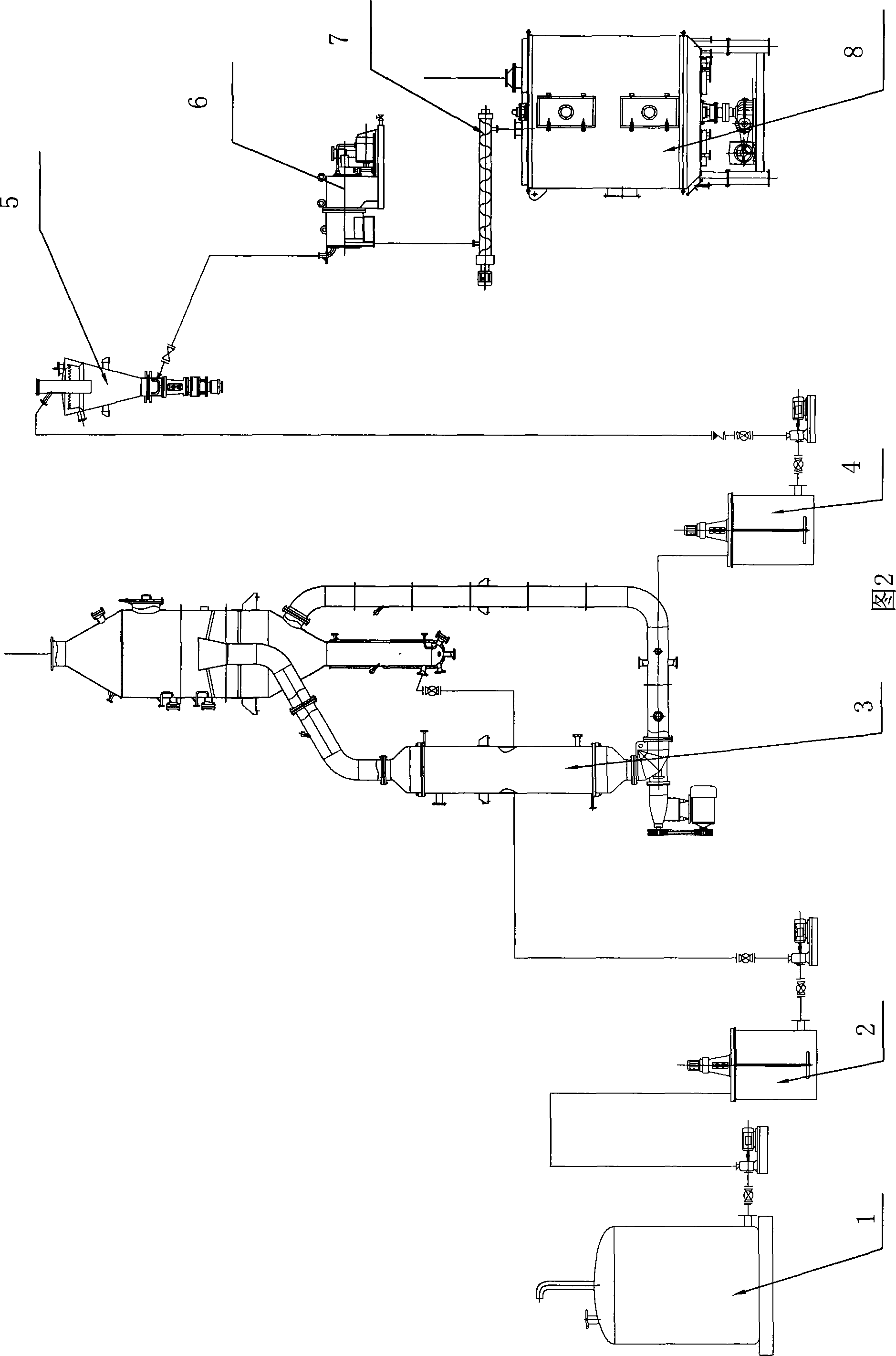

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

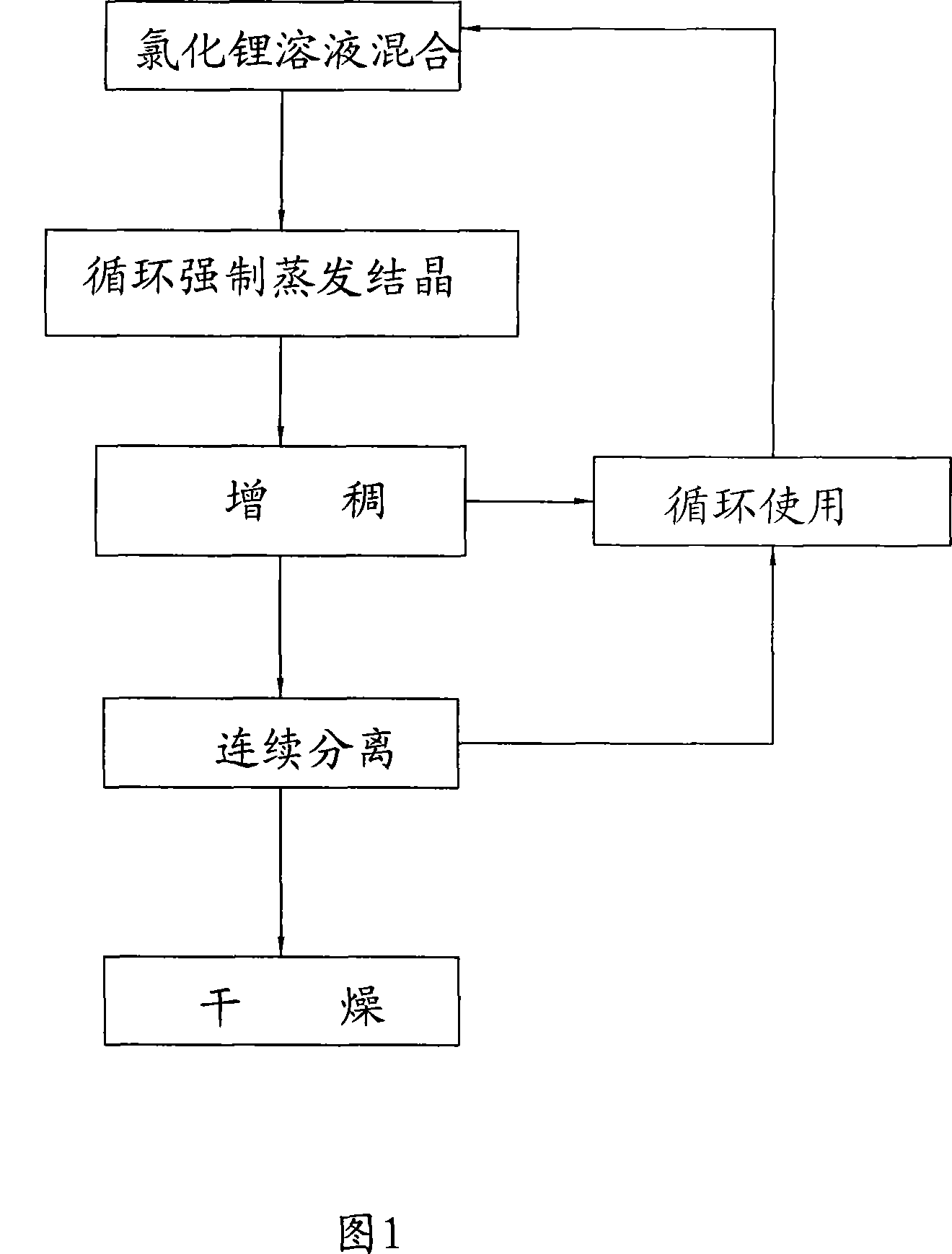

[0028] A kind of crystalline anhydrous lithium chloride production method of the present invention, please refer to Fig. 1, concrete steps are:

[0029] a. Solution mixing: Lithium chloride purification solution and lithium chloride magma separation mother liquor are mixed in feed tank 2, in this step the mother liquor that contains the solution of lithium chloride and the separation of lithium chloride magma separation is in the mother liquor of circulation Mixing in the trough;

[0030] b. Forced circulation evaporative crystallization: pump the mixed solution of lithium chloride solution and lithium chloride magma separation mother liquor into the forced circulation evaporative crystallizer 3 and circulate evaporative crystallization at 170°C-180°C to obtain and discharge the magma concentration It is a crystal slurry of 30%-35% solid lithium chloride. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com