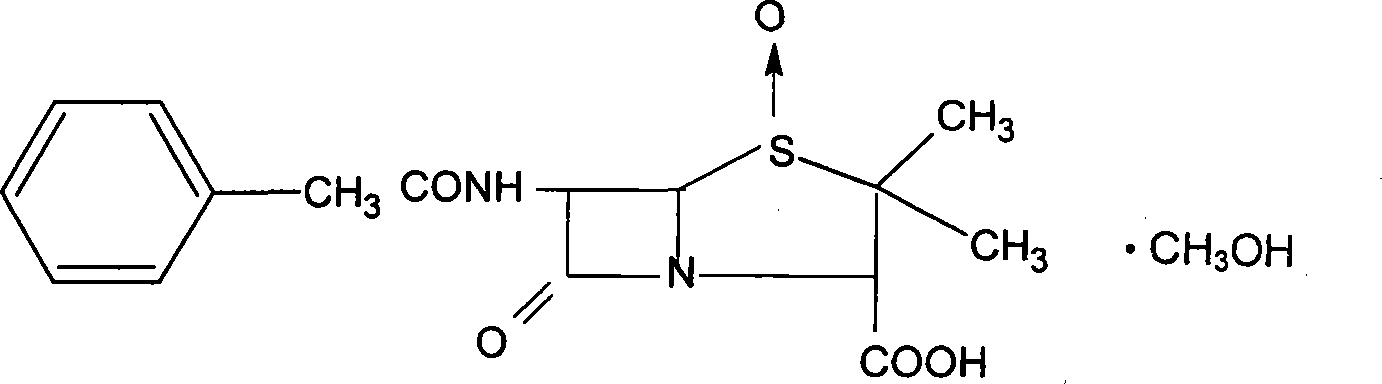

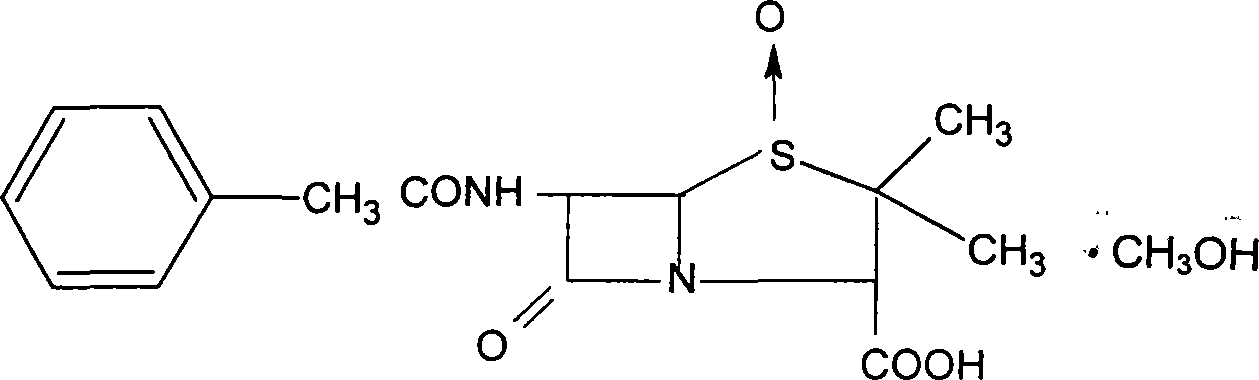

Penicillin G sulfoxide composite crystal and preparation method thereof

A technology of composite crystals and penicillin, applied in the direction of organic chemistry, can solve the problems of unfavorable use and storage, and achieve good effect, high stability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] At room temperature, put 10 grams of penicillin G sulfoxide (moisture content 0.2%) into the there-necked flask, add 150 milliliters of methanol, and under stirring at 120 rpm, use a 60°C water bath to heat up the material to 50°C to dissolve to form penicillin G Methanol solution of sulfoxide. The water bath was removed, and the solution was gradually cooled to 10°C with ice water. During this period, methanol complex crystals of penicillin G sulfoxide gradually precipitated, then the ice water was removed, and the material was further cooled to -5°C with ice brine, and filtered. Wash with 10 ml of methanol and dry to obtain 10.5 g (96.6%) of methanol complex crystals of penicillin G sulfoxide.

[0043] Listed below are the X-ray powder diffraction patterns of the obtained crystals obtained by passing copper rays of λ=1.54059 angstroms through a monochromator silk filter.

[0044] X-ray powder diffraction pattern

[0045] d

[0046]

[0047] w...

Embodiment 2

[0049] At room temperature, put 10 grams of penicillin G sulfoxide with a water content of 20% into the there-necked bottle, add 100 milliliters of methanol and 50 milliliters of water, and stir at 150 rpm, use a 50°C hot water bath externally to heat up the material to 45°C, stirring and dissolving to form penicillin G sulfoxide in methanol aqueous solution. The water bath was removed, and the solution was gradually cooled to 15°C with ice water. During this period, methanol complex crystals of penicillin G sulfoxide gradually precipitated, then the ice water was removed, and the material was further cooled to -10°C with ice brine, and filtered. Wash with 10 ml of methanol and dry to obtain 8.4 g (97%) of methanol complex crystals of penicillin G sulfoxide.

Embodiment 3

[0051]At room temperature, put 10 grams of penicillin G sulfoxide with a water content of 20.0% into the three-necked flask, add 140 ml of methanol, 30 ml of toluene and 28 ml of water, and use a 70°C hot water bath for external use under stirring at 200 rpm , raising the temperature of the material to 60°C, stirring and dissolving to form a mixed solvent solution of penicillin G sulfoxide. The hot water bath was removed, and the temperature of the solution was gradually lowered to 10°C with ice water. During this period, methanol complex crystals of penicillin G sulfoxide were gradually precipitated. The ice water was removed, and the material was further cooled to -5°C with ice brine, and filtered. Wash with 10 ml of methanol and dry to obtain 8.5 g (97.8%) of methanol complex crystals of penicillin G sulfoxide of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com