Hydraulic shock absorber

一种液压缓冲器、贮液器的技术,应用在液压缓冲器领域,能够解决环状部件变形、密封性下降、异物混入等问题,达到减轻压力、减少尺寸、简化装配的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

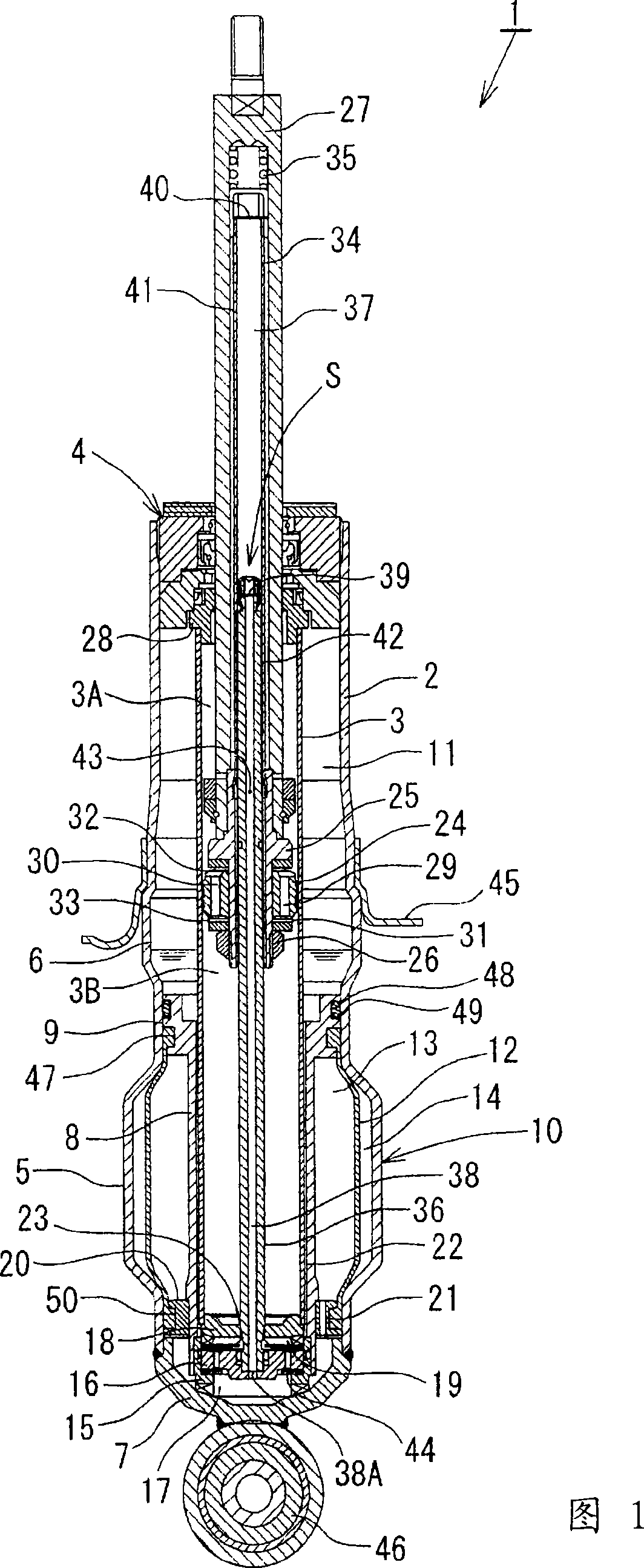

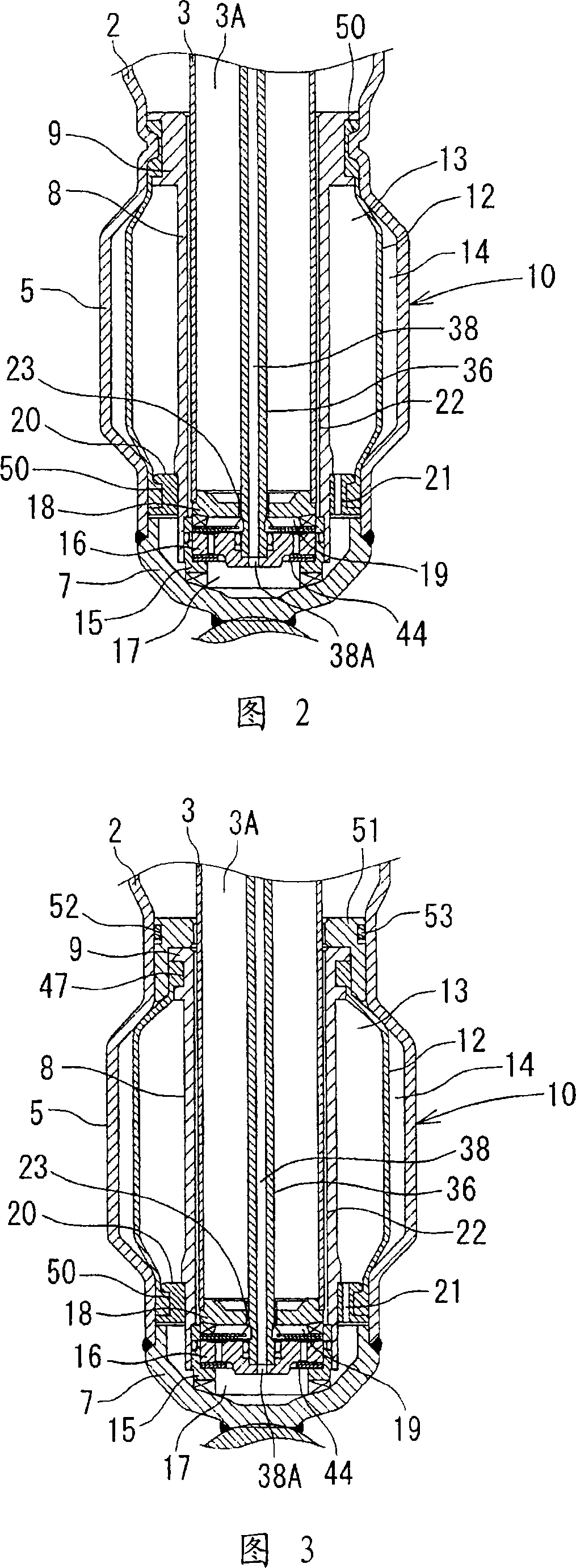

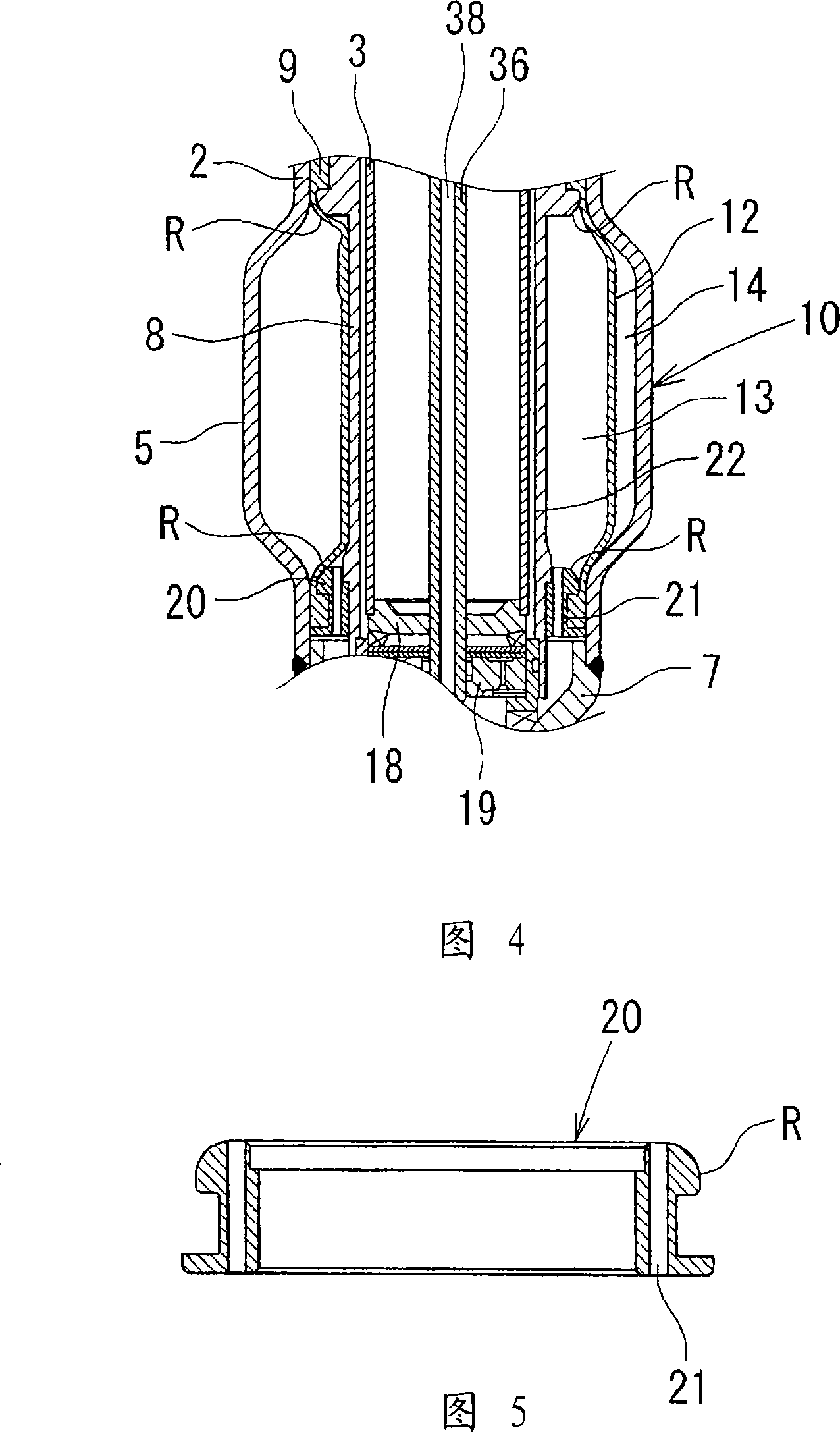

[0023] An embodiment of the present invention will be described in detail below according to the accompanying drawings.

[0024] As shown in FIG. 1 , the hydraulic shock absorber 1 has a double-cylinder structure in which a cylinder 3 is inserted into a substantially bottomed cylindrical casing 2 (outer cylinder). The sealing member 4 is attached to the opening of the casing 2 to form an annular chamber between the casing 2 and the cylinder 3 . In the case 2, the lower end portion side is expanded by bulging processing or the like, and the expanded diameter portion 5 is formed. The upper portion of the diameter-expanding portion 5 is slightly enlarged in diameter to form the spring holder support portion 6 . The cover member 7 is welded to the bottom of the casing 2 to block the bottom of the casing 2 . The partition member 8 is inserted between the enlarged diameter portion 5 of the casing 2 and the cylinder 3, and the outer flange portion 9 formed on the upper end of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com