Method for thinning a sample and sample carrier for performing the method

A sample and carrier technology, used in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., to solve problems such as hindering the automation of thinning processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

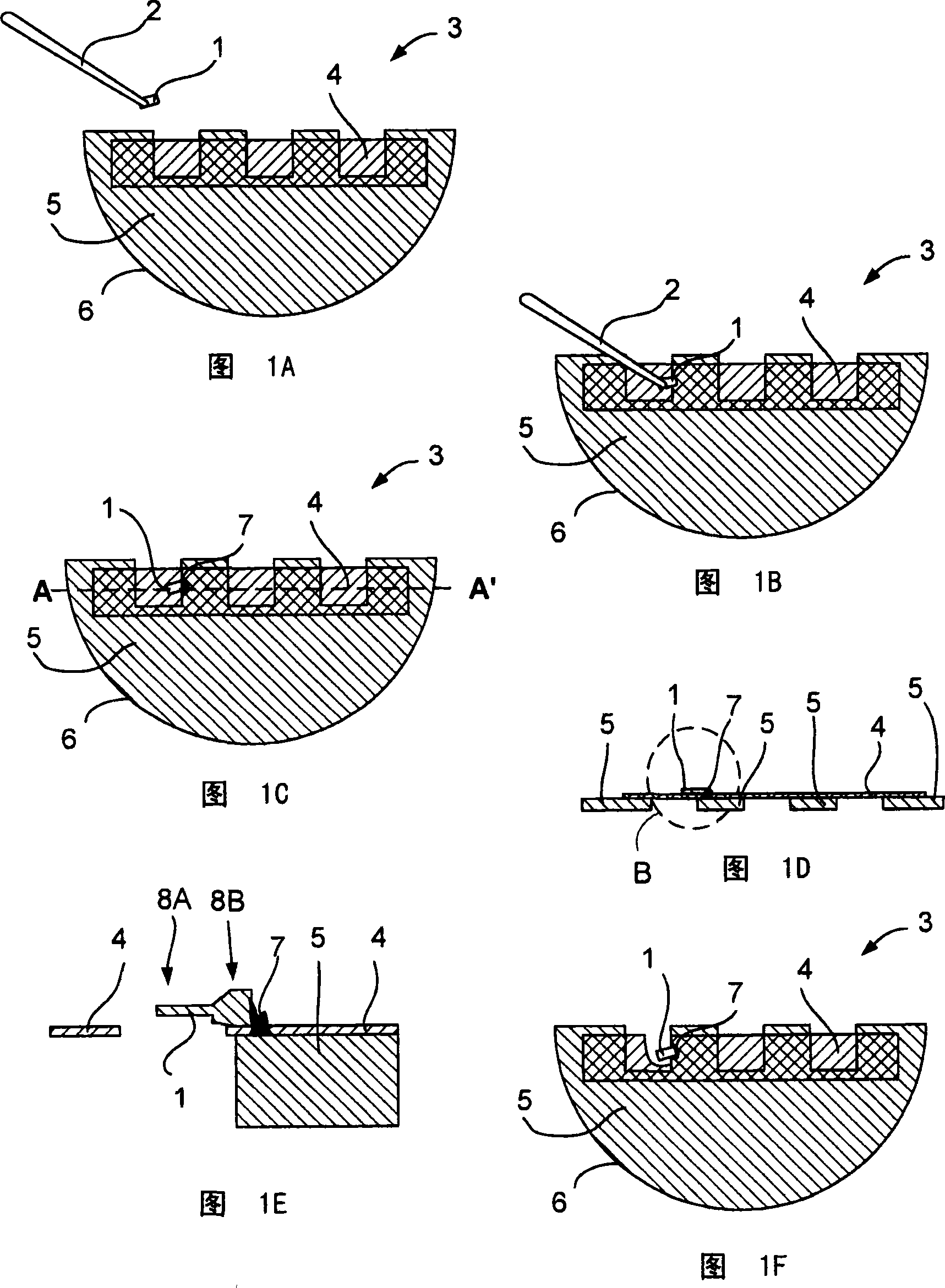

[0052] Figure 1A schematically depicts a sample carrier according to the invention and a probe carrying a sample approaching the sample carrier.

[0053] FIG. 1A shows a sample 1 attached to a probe 2 . The sample carrier 3 consists of two parts, a support membrane 4 and a rigid structure 5 . The rigid structure exhibits an outer boundary6. The supporting membrane extends partially beyond this outer boundary 6 of the rigid structure 5 .

[0054] The rigid structure of the sample carrier can be copper foil. Other materials, preferably electrically conductive materials, can likewise be used. Likewise, the support film is preferably electrically conductive, such as a carbon film or a conductive polymer film. However, support films made of silicon or, for example, nitride are also conceivable.

[0055] The sample 1 may be attached to the probe 2 by electrostatic forces, for example to a probe in the form of a charged glass electrode. Other attachment means can also be used, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com