Tillage machine for recycling stalk to farmland

A technology for tilling machine and straw, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of single function, unstable operation quality, poor leveling and compacting effect, etc., to eliminate environmental pollution, reduce The burden of farmers and the effect of improving social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

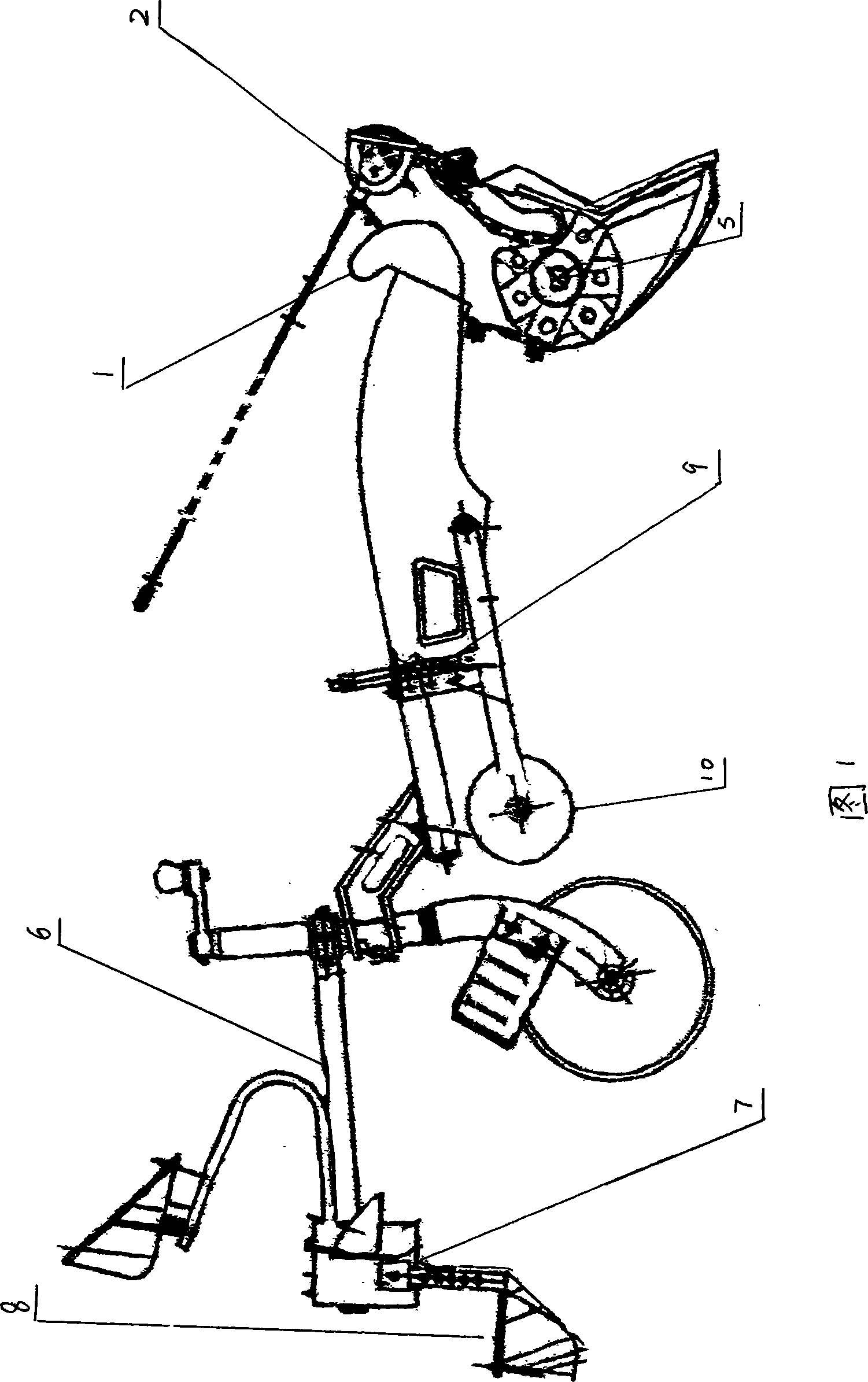

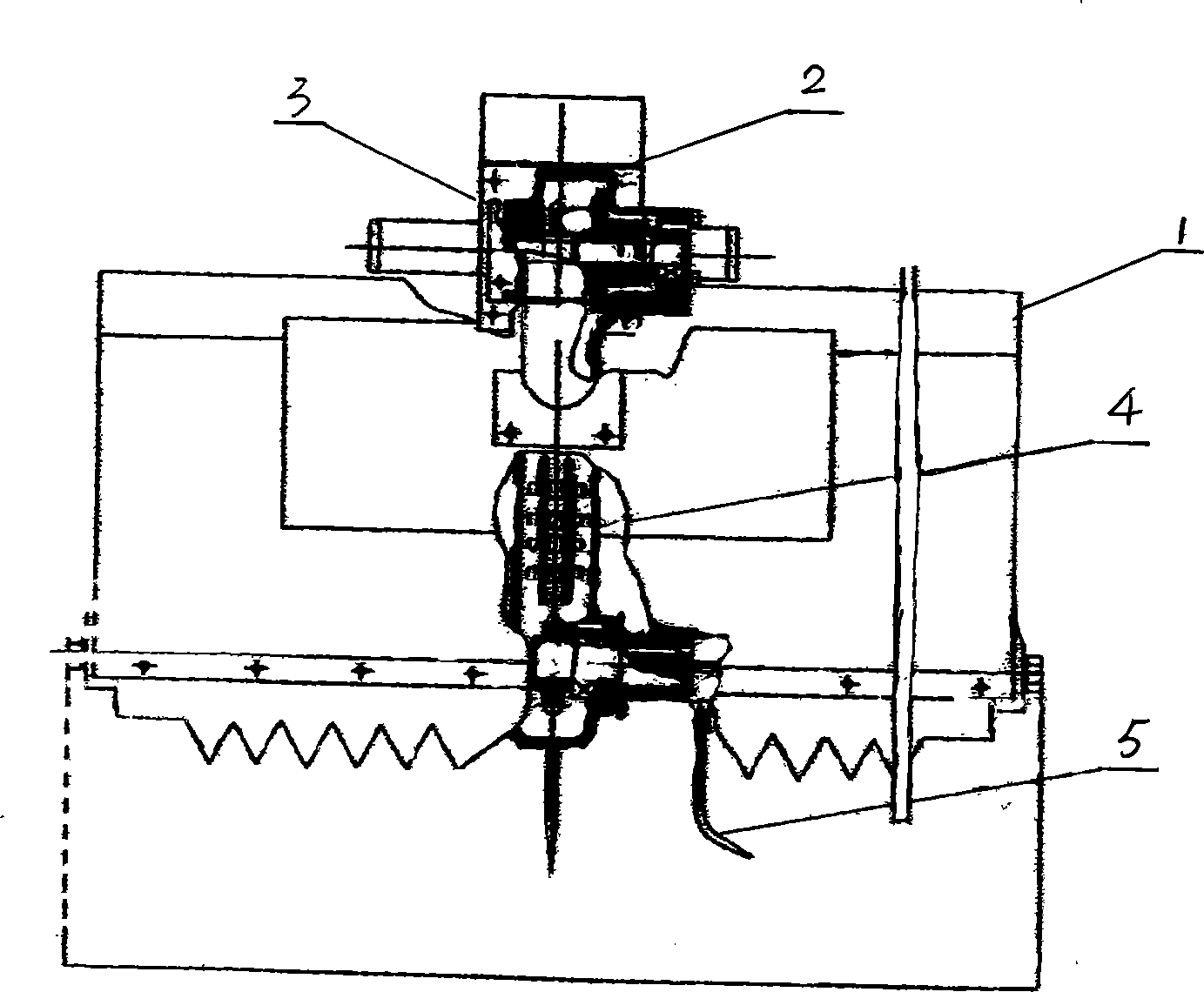

[0010] As shown in Figures 1 and 2: a straw returning plowing machine, including a hook device 1, an intermediate transmission device 2, a gear 3, a chain transmission device 4, a rotary cutter 5, a tailstock 6, and a leveler control device 7. Scraper assembly 8, grass pressing shaft adjustment device 9 and grass pressing wheel 10, the intermediate transmission device 2 is connected to the hitch device 1, the hitch device 1 is connected to the power machine, and the gear 3 passes through the chain drive device 4 Drive the rotary cutter 5, the scraper assembly 8 is installed on the tailstock 6 through the scraper operating device 7, and the grass pressing wheel 10 is installed on the hitch 1 through the grass pressing shaft adjusting device 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com