Method for applying brazing filler metal on metallic carrier plain film

A metal carrier and flat sheet technology, applied in metal processing equipment, catalyst carriers, chemical instruments and methods, etc., can solve the problems of high production cost, affecting compressive strength, overlapping and crossing of brazing rods, etc., and achieve low production cost , stable quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

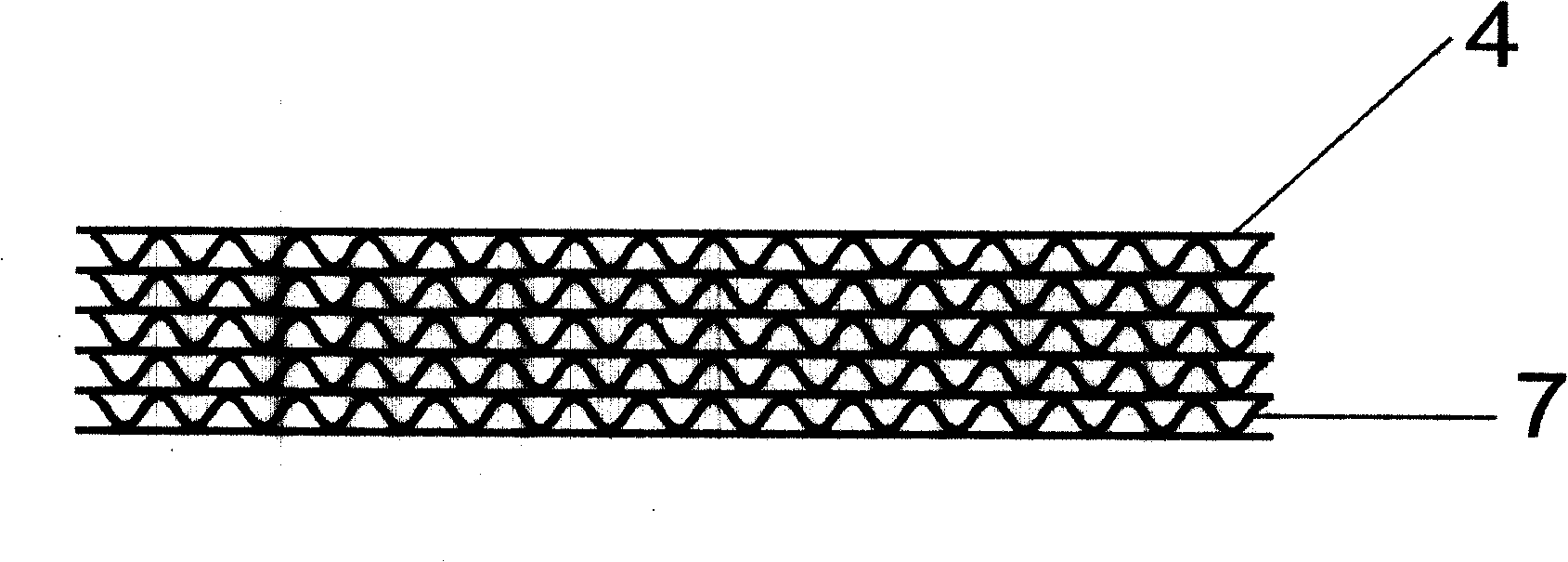

[0018] see Figure 5 with Image 6 First, the strip-shaped nickel-based brazing material 5 is pressed on the required seam welding position with the seam welder roller 6, and the strip-shaped nickel-based brazing material 5 is positioned with a positioning device (not shown in the figure of the positioning device), The flat sheet material barrel 8 is moved by the feeding device 10 along the direction of the arrow "→" in the figure. The seam welder roller 6 installed in the seam welder 9 seams the strip-shaped nickel-based brazing material 5 on the metal carrier inner core plate sheet 4 . Finally, the flat sheet 4 of the strip-shaped nickel-based brazing material 5 that has been rolled and welded is cut to a required length with a cutter 11 . The position, quantity and width of seam welding required for the strip-shaped nickel-based brazing material 5 are determined according to the desired position, quantity and width of the brazing connection. The strip-shaped nickel-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com