Ceramic antenna preparation method

A ceramic antenna and ceramic substrate technology, applied in ceramic molding machines, manufacturing tools, radiating element structures, etc., can solve problems such as low production efficiency and accuracy, and achieve high production efficiency, excellent electrical conductivity, and low electrical loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

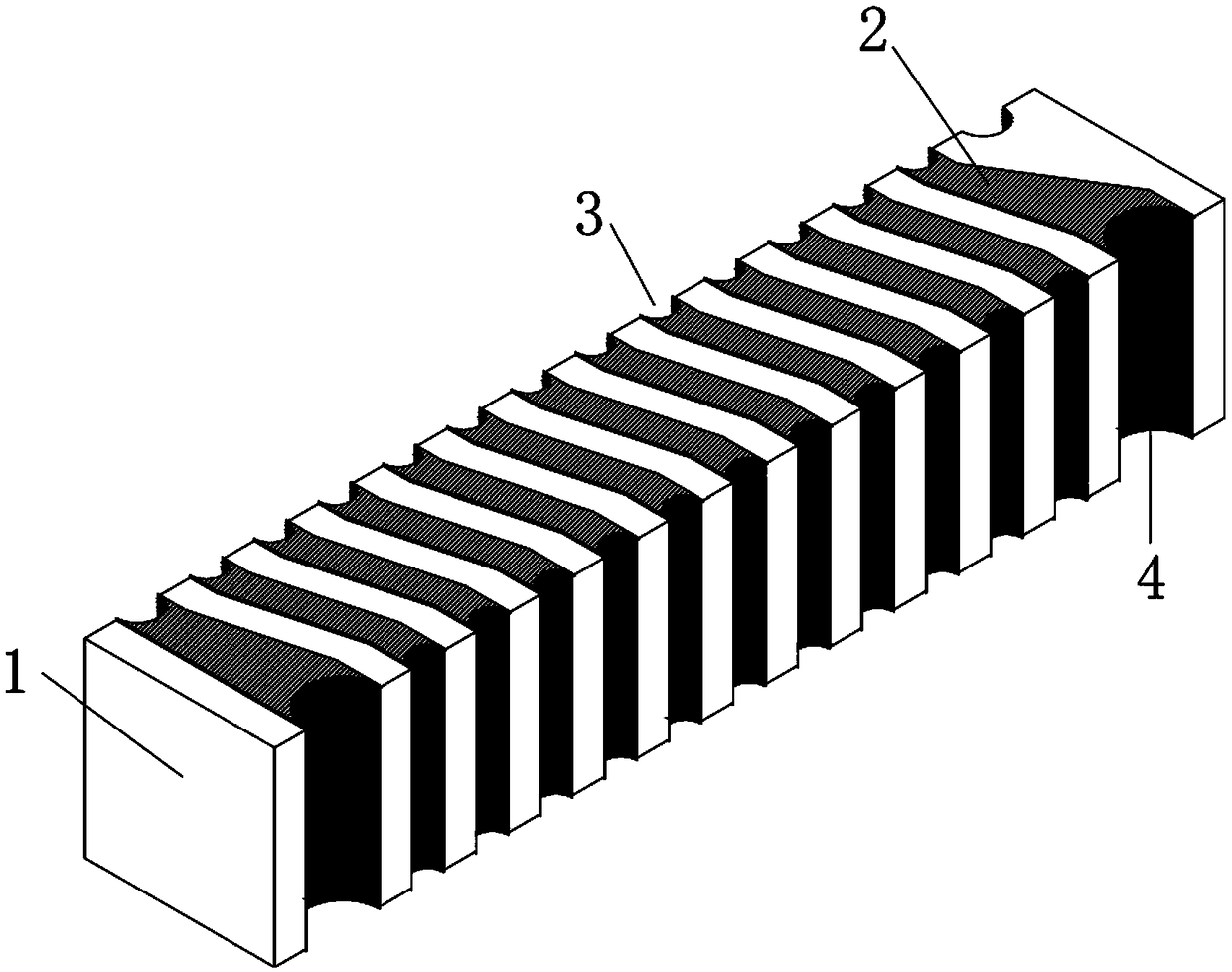

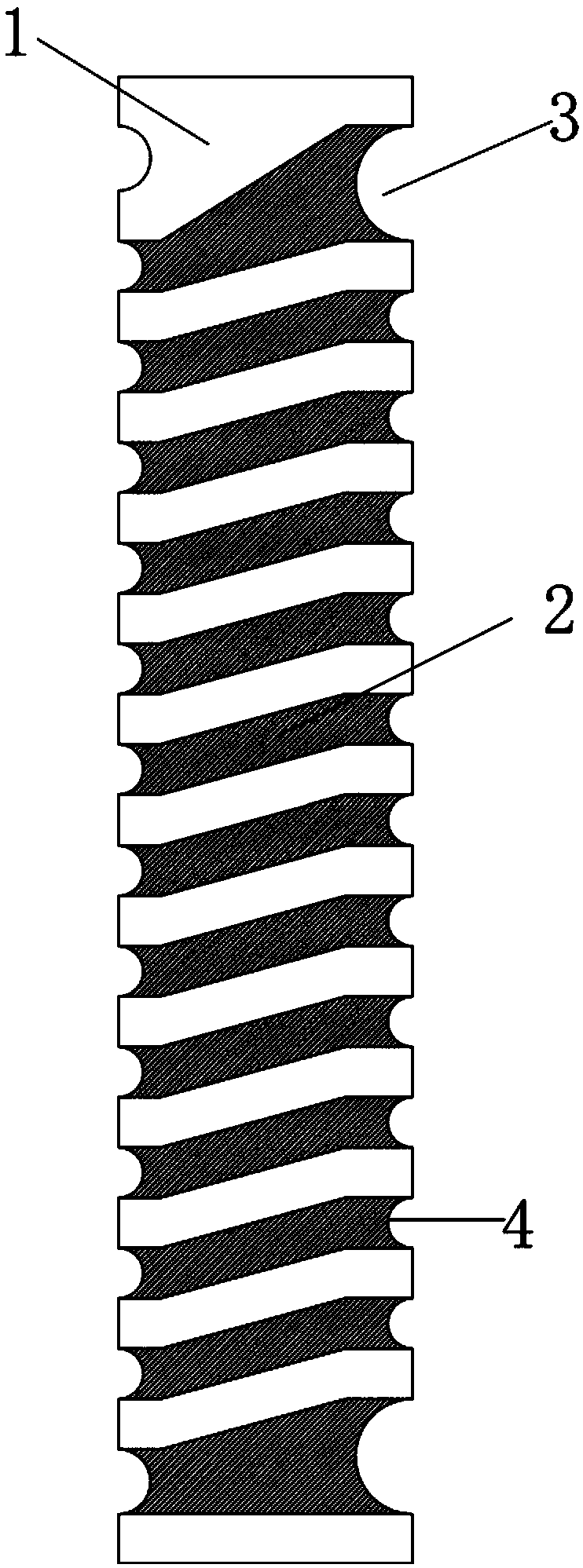

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0029] A preparation method of a ceramic antenna provided by the present invention comprises the following steps:

[0030] Step 1: Tape-casting, on the carrier plate, through a certain speed, and at a temperature of 40-75°C, tape-cast the ceramic slurry used to obtain a green ceramic sheet with a certain thickness;

[0031] Step 2: Cutting, cutting the cast green ceramic sheet to obtain the green ceramic sheet of the required size;

[0032] Step 3: Lamination, stack the cut green ceramic sheets together, put them into the warm water isostatic pressing equipment, and pressurize at a certain temperature to form the green substrate;

[0033] Step 4: Punching, according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com