Motor tricycle and single-cylinder engine thereof

A technology of three-wheeled motorcycles and engines, which is applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of increased burden, unreliable work, and large space occupation, so as to reduce maintenance costs and time, improve assembly accuracy, reduce The effect of occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

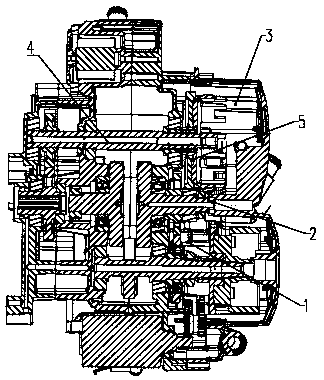

[0027] Embodiment 1: as figure 1 As shown, a single-cylinder engine for a three-wheeled motorcycle includes a heat engine 1 and a clutch 3. The crankshaft 2 of the heat engine 1 is arranged longitudinally, and the output end of the crankshaft 2 is located at the front end.

[0028] Using the single-cylinder engine set in this embodiment, the installation of the heat engine on the vehicle frame is rotated by 90° to realize the longitudinal output of the crankshaft 2 of the heat engine 1. In this way, the transmission efficiency of the single-cylinder engine can be improved, and the engine’s load can be reduced. Fuel consumption and reduced engine emissions.

[0029] Wherein, in order to realize that the engine can transmit power to the rear axle, the power of the engine needs to be transmitted to the rear end of the heat engine 1 for output. In this embodiment, the output end of the crankshaft is connected to the input end of the clutch through the primary transmission gear. ,...

Embodiment 2

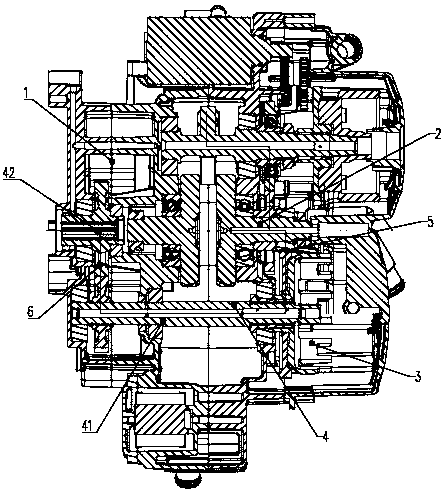

[0036] Embodiment 2: as figure 2 As shown, a three-wheeled motorcycle engine includes a heat engine 1 and a clutch 3. The crankshaft 2 of the heat engine 1 is arranged longitudinally. connected, the output end of the clutch 3 is output from the rear end of the heat engine 1 through the reversing device 4 . The output end of the crankshaft 2 at the front end means that the crankshaft 2 is arranged longitudinally and its output direction faces forward. In this embodiment, the clutch is a multi-plate wet clutch.

[0037] In this embodiment, the reversing device 4 outputs through the right side of the crankshaft 2, and the reversing device 2 changes the forward output direction of the crankshaft 2 into a backward output direction to finally realize the output.

[0038] The clutch 3 is connected to the crankshaft 2 through a straight or helical gear pair A5 for primary transmission, and the output end of the clutch 3 faces backward and is connected to the input end of the revers...

Embodiment 3

[0045] Embodiment 3: This embodiment is a further improvement on the basis of Embodiment 2.

[0046] In this embodiment, in order to further make the output speed of the engine meet the input speed of the transmission arranged thereafter, a speed reduction mechanism is also provided on the crankshaft 2 to the output end of the engine, wherein the speed reduction mechanism It can be set separately, and can be set together with the reversing mechanism or the clutch.

[0047] Wherein, the deceleration device can be the gear pair A5, which can reach the input speed of the transmission through the first-stage deceleration of the gear pair A5; the deceleration device can also be the gear pair B6, which can reach The input speed of the transmission; the reduction device can also be a spur gear pair A5 and a spur gear pair B6, through the two-stage reduction of the spur gear pair A5 and the spur gear pair B6 to reach the input speed of the transmission.

[0048] In this embodiment, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com