Method for manufacturing middle-temperature ceramics for daily use crackle glaze

A production method and cracked glaze technology are applied in the field of cracked glaze on the surface of daily ceramics and its ingredients, which can solve the problems of product color absorption, brittleness, and only suitable for small products, and achieve the effect of bright color and rich color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

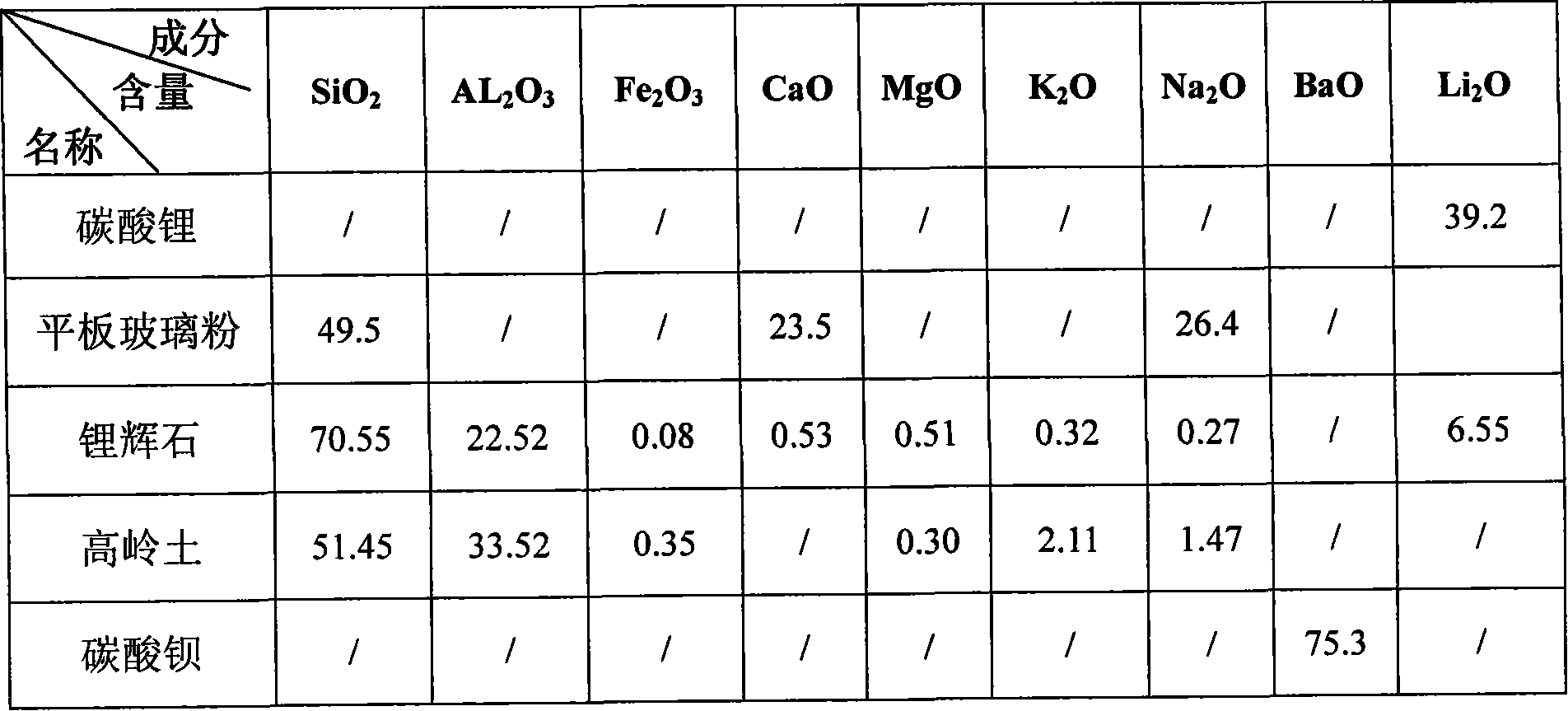

[0033] A widely used scheme is a cracked glaze suitable for medium-temperature daily-use white porcelain. On the basis of the conventional cracked glaze, lithium-containing raw materials are added, and part of the raw materials are made into cracked frit. The glaze raw materials are made by mixing the conventional white porcelain body materials, and then the glaze slurry is made by adding water ball mill; the glaze slurry is applied to the white clay green body, dried and then put into the kiln, and fired at 1240~1280℃ to crack glaze. The specific technical scheme is described as follows:

[0034] The crafting formula of the glaze, in parts by weight, is as follows:

[0035] 50 parts of cracked frit, 15 parts of spodumene

[0036] 15 parts of barium carbonate 20 parts of kaolin

[0037] The chemical composition of cracked glaze prepared according to the above process formula is as follows:

[0038] SiO 2 : 48.95% Al 2 O 3 : 9.86%

[0039] K 2 O: 0.74% Na 2 O: 13.58%

[0040] Li 2 ...

Embodiment 2

[0045] A cracked glaze suitable for medium temperature white porcelain, the specific technical scheme is as follows:

[0046] The process formula of the ingredients, the proportion of parts by weight is:

[0047] 70 parts of cracked frit, 10 parts of spodumene, 8 parts of barium carbonate

[0048] 8 parts of kaolin, 2 parts of copper oxide

[0049] The chemical composition of cracked glaze prepared according to the above process formula is as follows:

[0050] SiO 2 : 47.78% Al 2 O 3 : 5.38% K 2 O: 0.53%

[0051] Na 2 O: 17.31% Li 2 O: 3.87% CaO: 16.7%

[0052] BaO: 6.02% MgO: 0.06% CuO: 1.98%

[0053] The production method is as follows:

[0054] Weigh various raw materials accurately according to the process requirements, put the raw materials into the ball mill according to the raw materials: ball stone: water = 2:2:0.8, ball mill for 24 hours, the glaze slurry fineness is 250 mesh sieve, and the sieve residue is 0.08~0.1%. Pass a 160-mesh sieve. Add 1‰ to 2‰ of ammonium chlori...

Embodiment 3

[0056] A cracked glaze suitable for medium-temperature daily-use white porcelain. The specific technical scheme is as follows:

[0057] The glaze is composed of a base glaze and a coloring agent, and its composition is composed of 98% of the base glaze and 2% of the coloring agent. The coloring agent is a ceramic pigment: silver gray.

[0058]The process formula of the ingredients, the proportion of parts by weight is:

[0059] 50 parts of cracked frit, 20 parts of spodumene, 10 parts of barium carbonate

[0060] 15 parts of kaolin, 2 parts of silver ash

[0061] The chemical composition of the cracked glaze base glaze prepared according to the above process formula is as follows:

[0062] SiO 2 : 53.89% Al 2 O 3 : 7.62% K 2 O: 0.68%

[0063] Na 2 O: 14.11% Li 2 O: 3.05% CaO: 12.84%

[0064] BaO: 7.53% MgO: 0.08%

[0065] The production method is as follows:

[0066] Accurately weigh various raw materials according to the process requirements, put the raw materials i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com