High temperature compensator

A high-temperature compensator and high-temperature-resistant technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, pipelines to prevent damage/wear, etc., can solve the problem of reducing the service life of the compensator, affecting the compensation performance of the compensator, Sealing ring cannot be replaced and other problems, to achieve the effect of enhancing compensation ability, prolonging service life and shortening pouring length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

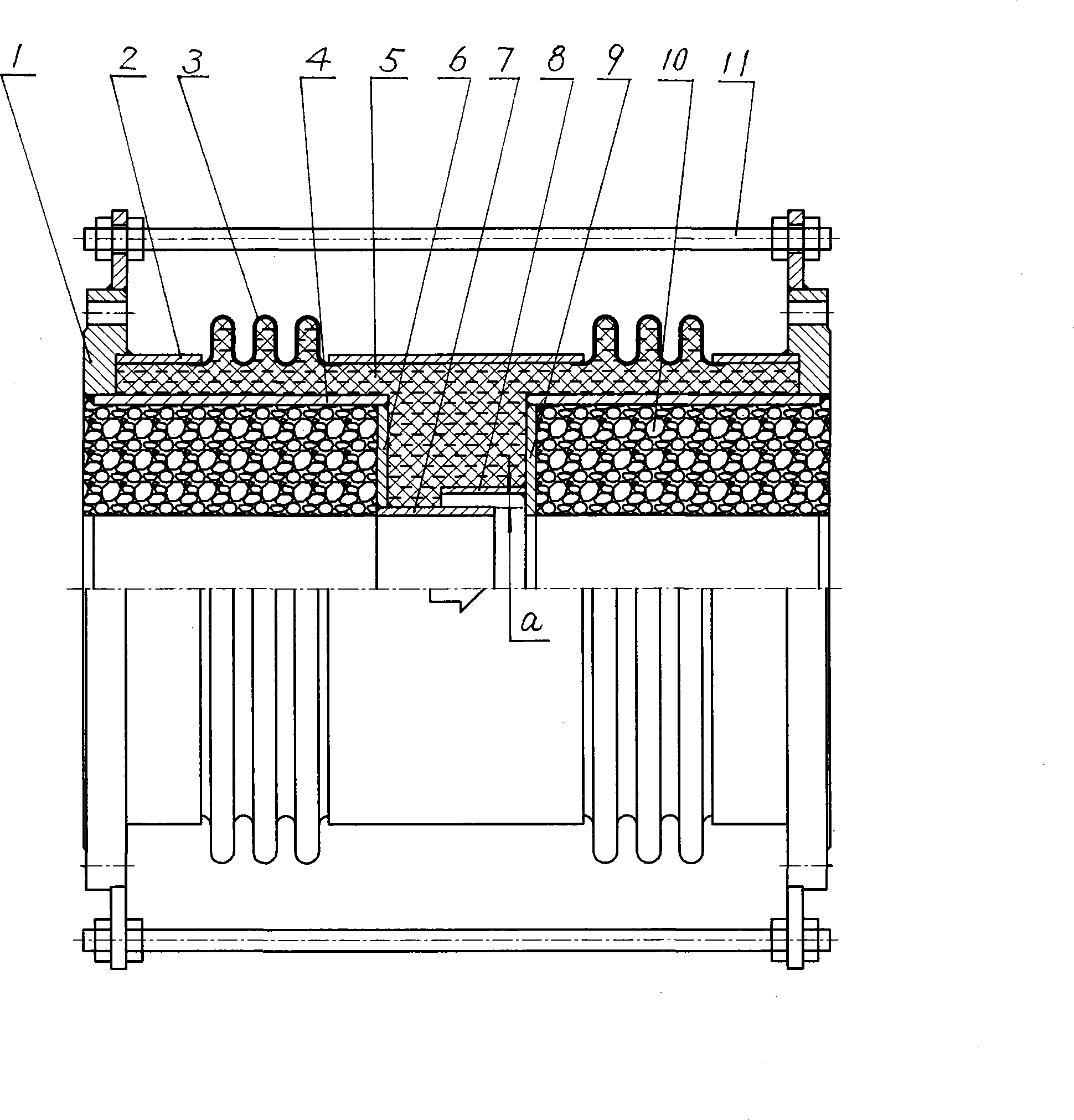

[0008] Referring to the accompanying drawings, flange 1, connecting pipe 2, and stainless steel bellows 3 are welded into the main body of the bellows compensator, which is provided with an inner liner 4 welded to the flange, and the inner liner is divided into two sections of equal length. The gap at the opposite end is provided with a telescopic ring composed of a guide tube ring plate 6, a guide tube 7, a sleeve 8, and a sleeve ring plate 9. The guide tube 7 and the sleeve 8 are made of heat-resistant steel 1Cr25Ni20Si2. The gap between the overlapping parts a=10mm, the bellows, the connection pipe and the liner pipe, and the inner cavity of the telescopic ring are filled with aluminum silicate ceramic fiber material 5 wrapped by stainless steel wire mesh, and the inner side of the liner pipe is cast with high-temperature refractory mud 10, refractory The mud inner wall and the guide tube are on the same cylindrical surface, and the two ends of the refractory mud are closely...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com