Millimeter wave radio frequency micro electro-mechanical system dual-frequency phase shifter with trough type coplanar waveguide structure

A micro-electromechanical system and coplanar waveguide technology, applied in waveguide devices, circuits, electrical components, etc., can solve problems such as high insertion loss, large excitation voltage, and complex structure, and achieve reduced overall size, clear organization, and easy processing The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

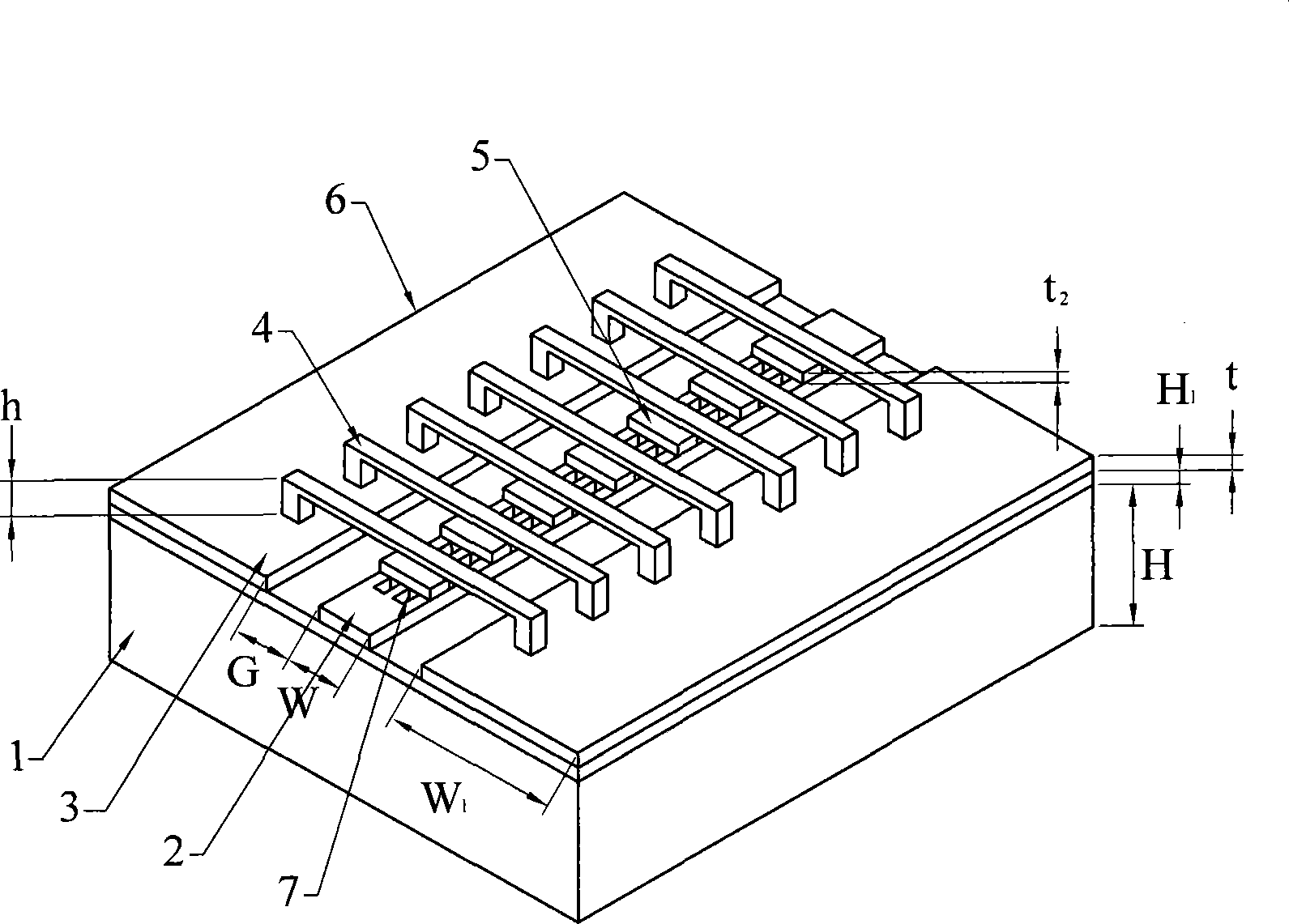

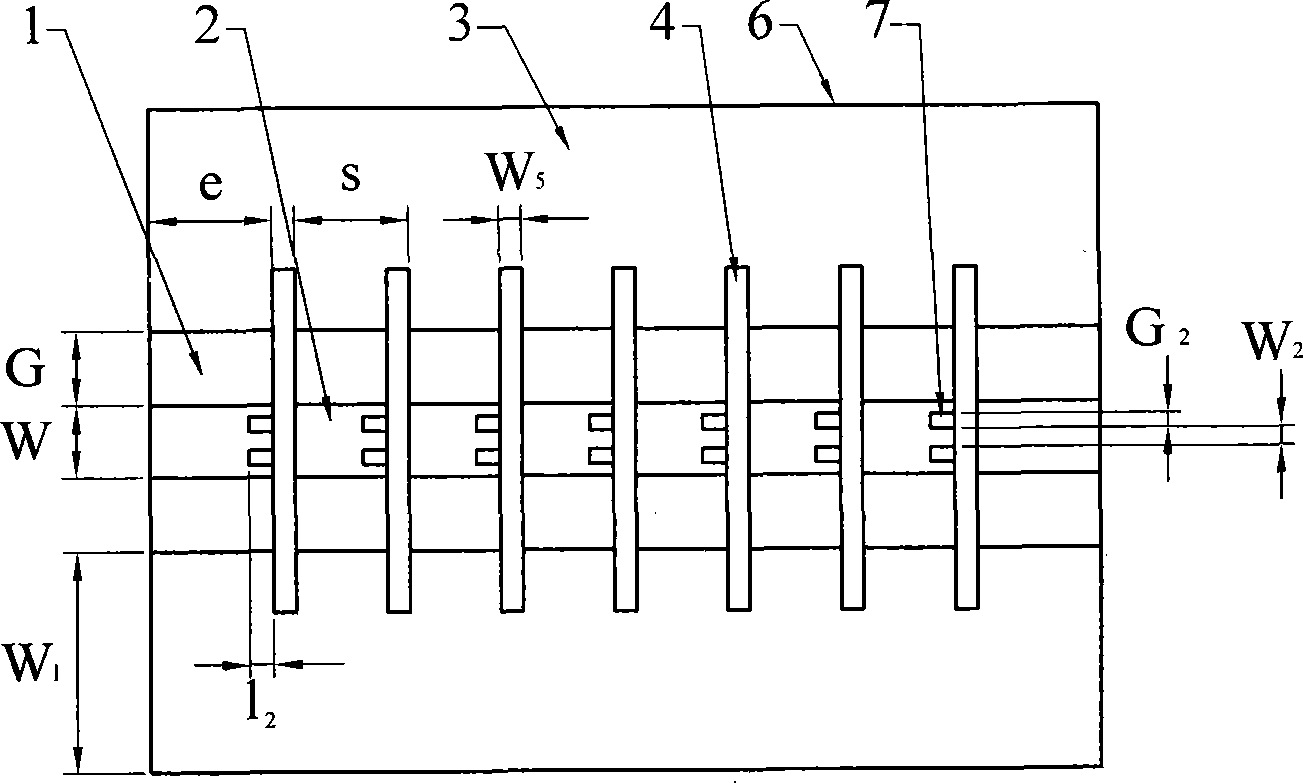

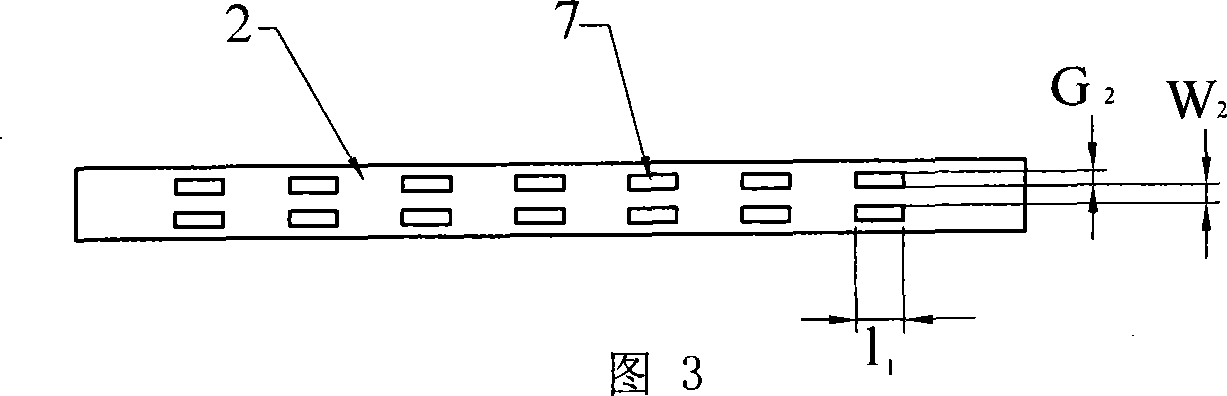

[0008] Specific implementation mode one: combine Figure 1 ~ Figure 4 This embodiment is described. This embodiment is composed of n metal bridges 4, n insulating dielectric substrates 5, and a coplanar waveguide 6. The coplanar waveguide 6 includes a substrate 1, a signal line 2, and two ground lines 3. The signal line 2 is fixed in the middle of the upper surface of the substrate 1, and the ground wire 3 is fixed at intervals on both sides of the signal line 2. The metal bridge 4 spans the substrate 1 of the coplanar waveguide 6, and the two adjacent metal bridges 4 The distance between them is S, the metal bridge 4 is perpendicular to the signal line 2, the two ends of each metal bridge 4 are respectively fixed on the two ground wires 3 on the coplanar waveguide 6, and the dielectric substrate 5 is fixed on On the upper surface of the signal line 2 below the metal bridge 4, the width of the dielectric substrate 5 is the same as that of the signal line 2, and the signal line...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 1 ~ Figure 4 Describe this embodiment, the difference between this embodiment and the specific embodiment is the length l of the rectangular groove 7 1 20~50μm, width G 2 5 to 30 μm. Other compositions and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 1 ~ Figure 4 Describe this embodiment, the difference between this embodiment and the specific embodiment is that each group of grooves leaks out the length l of the dielectric substrate 5 2 20 to 30 μm. Other compositions and connection methods are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com