Mosaic type elastic compound sieve plate

A mosaic and elastic technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problem of not meeting the needs of raw coal dry depth screening, not being able to solve the problem of process effect and screening efficiency, screening Unreasonable board structure and other problems, to achieve good practicability and application value, convenient and reliable card installation, and reasonable layout of screen surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

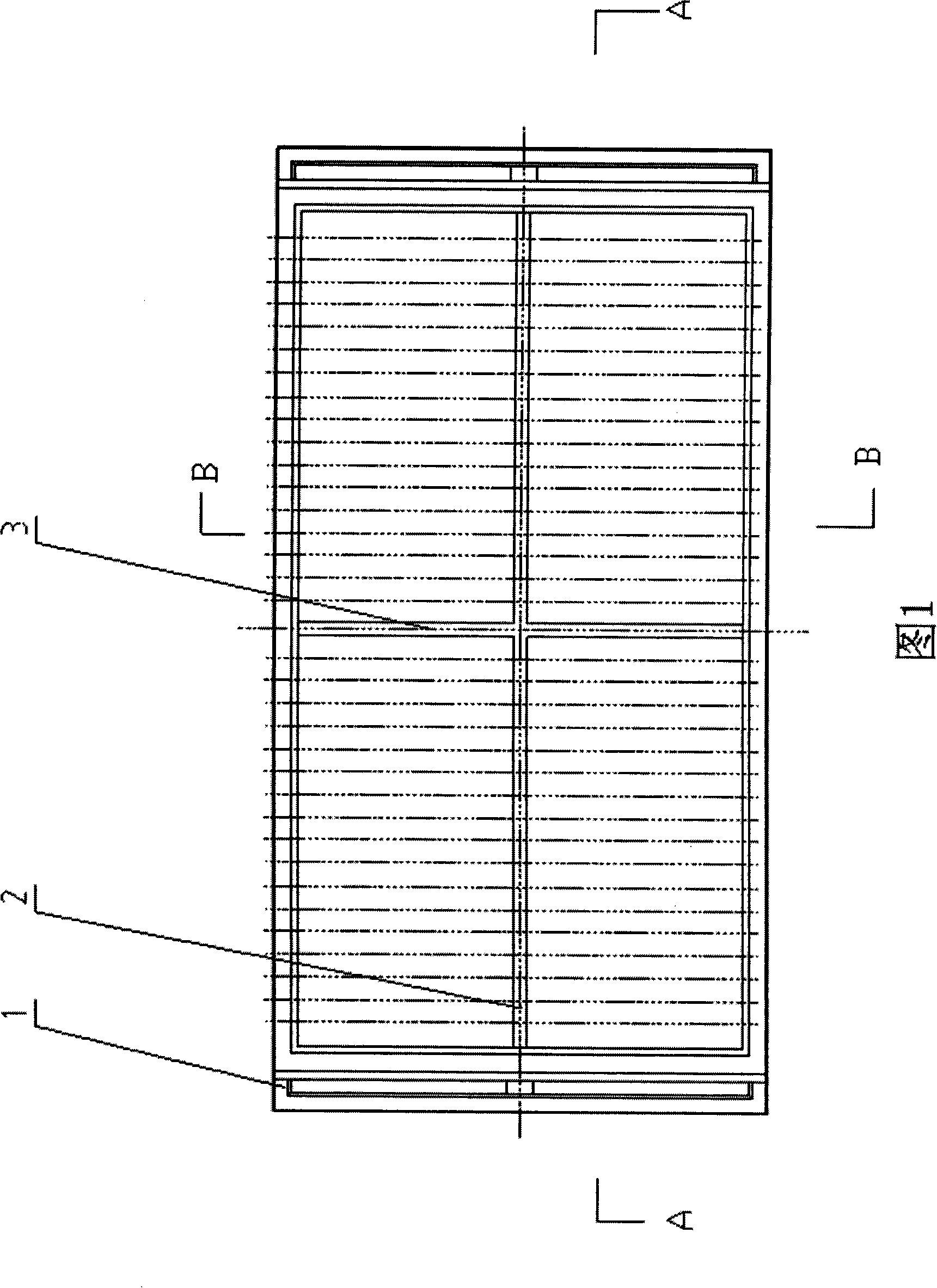

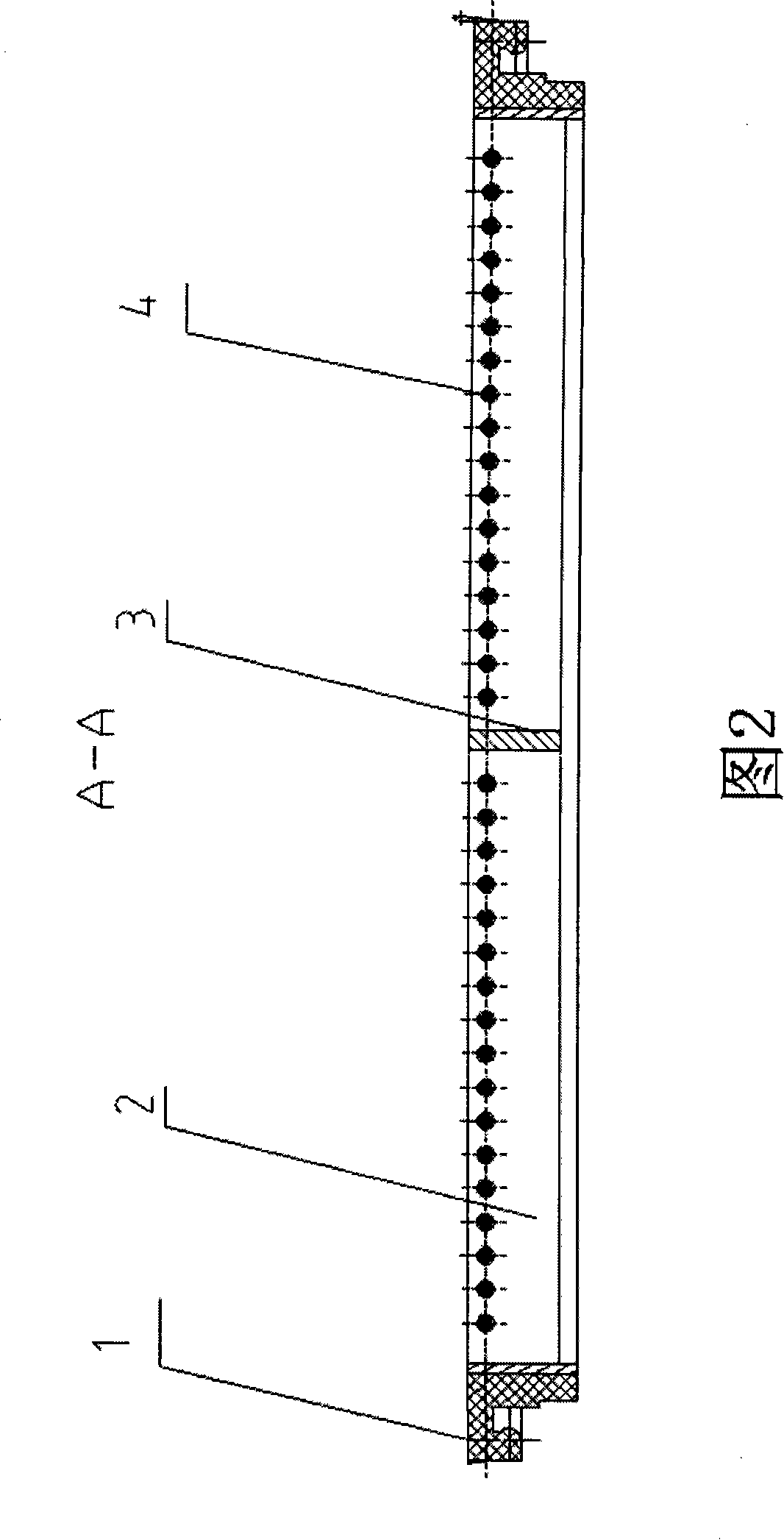

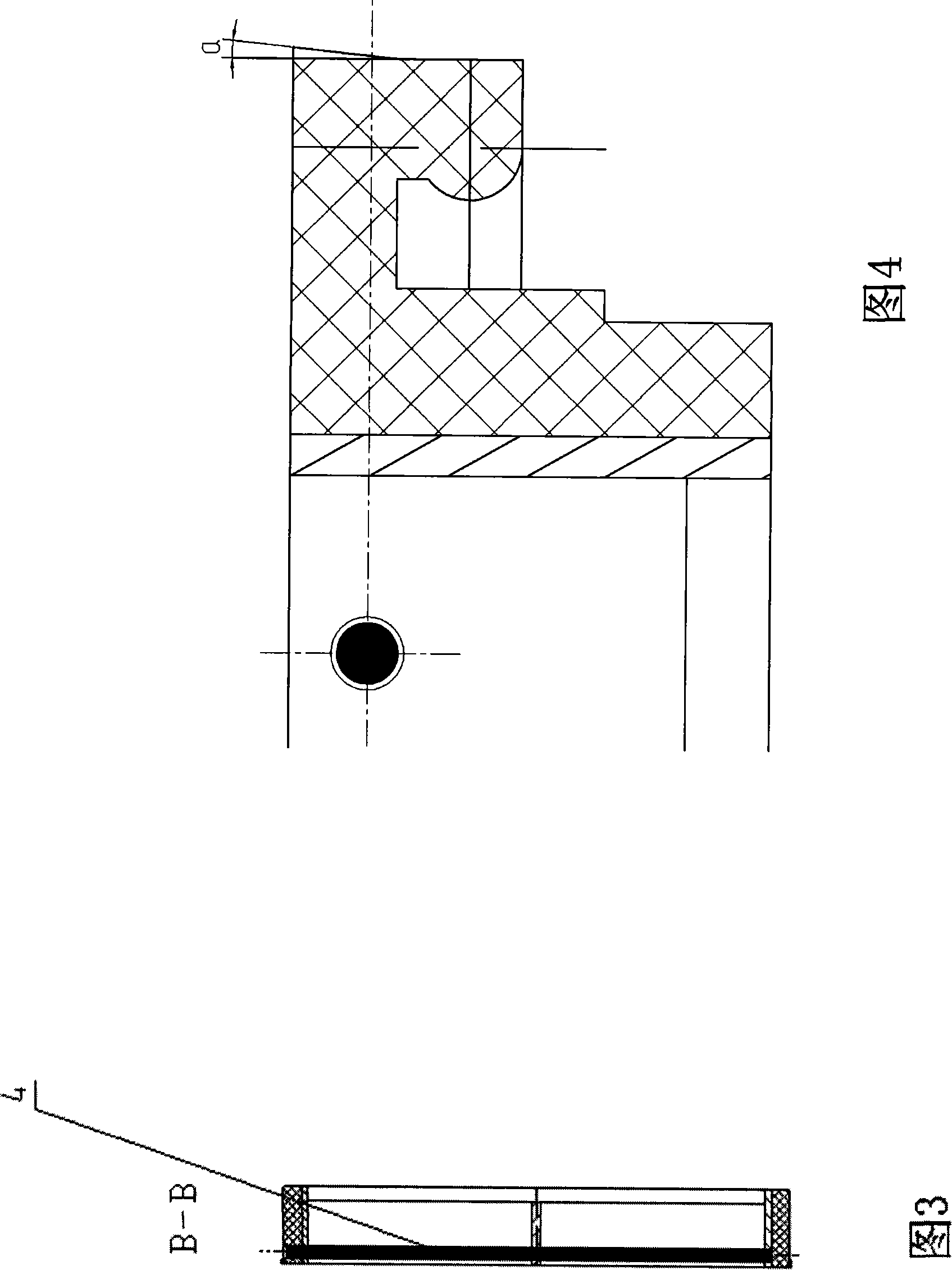

[0012] An implementation example of the present invention will be further described below in conjunction with accompanying drawing:

[0013] The mosaic elastic composite sieve plate of the present invention is mainly composed of a skeleton body 1, a skeleton crossbeam 2, a skeleton longitudinal beam 3 and an elastic screen rod 4, and the skeleton crossbeam 2 and the skeleton longitudinal beam 3 are vertically intersected and respectively fixed on the inner side plate of the skeleton body 1 , to strengthen the skeleton body 1. Skeleton body 1 is glued with polyurethane and 20g steel plate to form a composite structure elastic body frame. The polyurethane composite structure on both sides of the composite structure elastic body frame is in the shape of a groove, which is directly connected to the mosaic rail seat fixed on the load-bearing beam of the screen body. Fitting, that is, matching with the groove structure of the standard modular sieve plate rail seat. The end faces on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com