Dust absorption grinding bench system

A technology of grinding table and workbench, which is applied in the direction of grinding/polishing equipment, grinding/polishing safety device, metal processing equipment, etc. It can solve the problem that the grinding table cannot effectively remove dust and consume energy, so as to avoid heat loss and collect and process Convenience and high dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

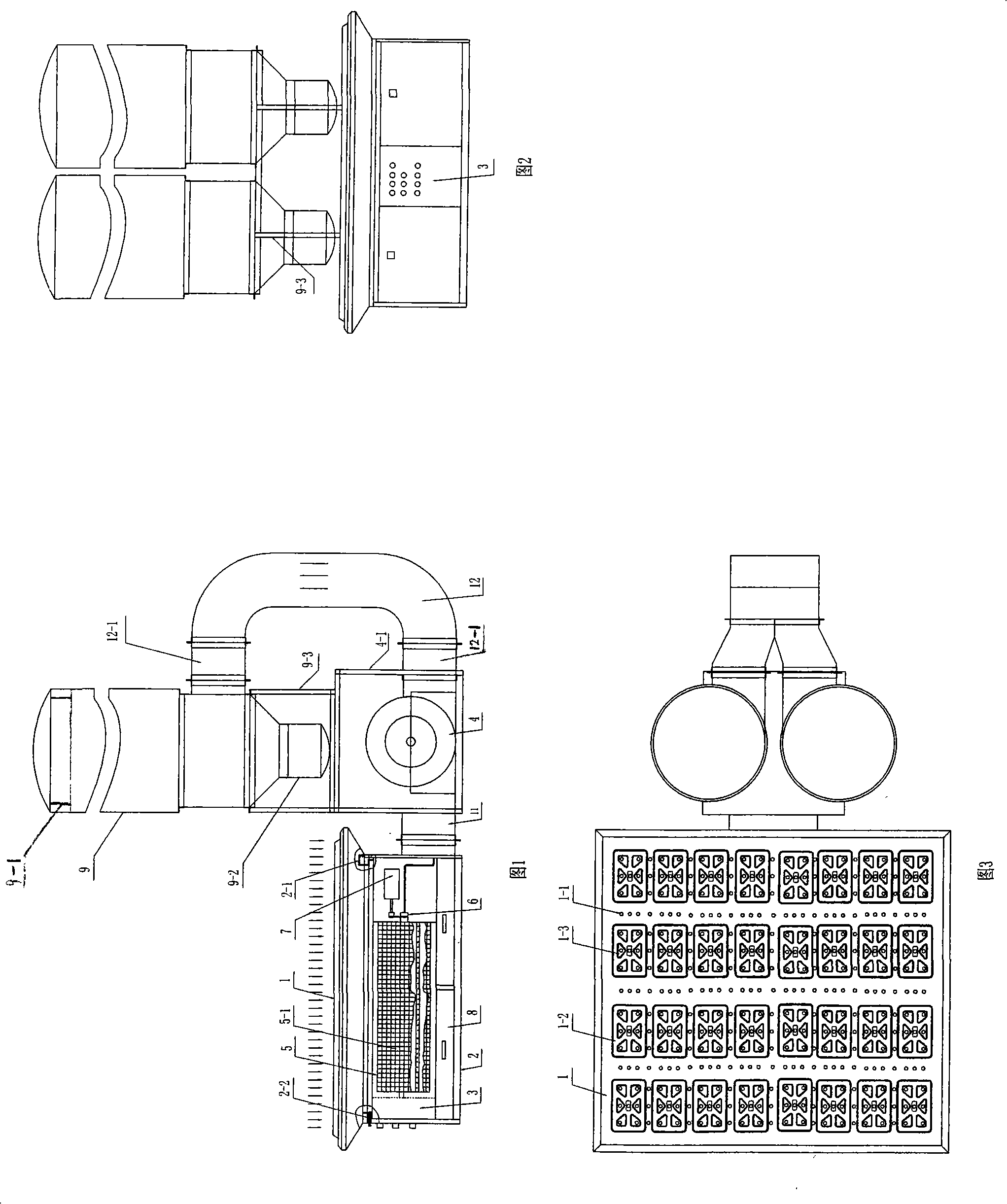

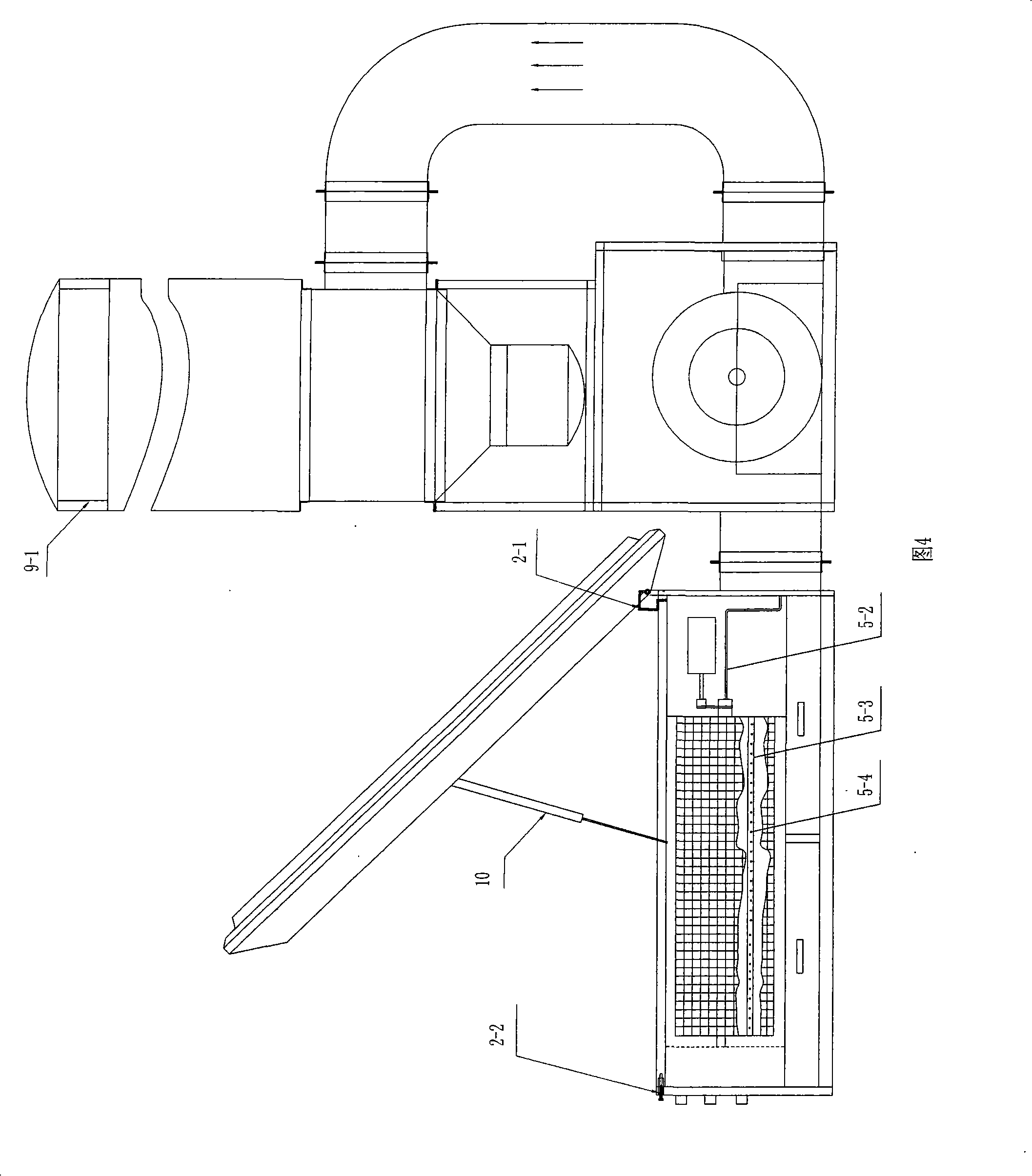

[0012] The vacuuming and grinding table system includes a workbench 1, a box body 2, an exhaust fan 4 and a dust collection barrel 9. One end of the box body 2 is connected to the exhaust fan 4 through the exhaust pipe 11, and the exhaust fan 4 is connected to the suction fan 12 through the elbow pipe 12. The dust bucket 9 is connected; the box body 2 is provided with a drum 5, and its surface is wrapped with filter cotton 5-1; one end of the box body 2 is provided with a deceleration motor 7, and the drum 5 is connected with the deceleration motor 7 through the pulley 6; the box body 2 The other end is provided with distribution box 3; the bottom of box body 2 is provided with dust collection drawer 8; The electric box 3 is electrically connected; the workbench 1 is provided with a through hole 1-1.

[0013] As shown in Figures 1, 2, and 3, turn on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com