Method for producing biological leaf fertilizer by using waste molasses of sugar plant

A technology of biological foliar fertilizer and waste molasses, which is applied in the direction of fertilizers made from biological wastes, applications, organic fertilizers, etc., can solve problems such as adverse environmental impacts, difficult treatment of molasses alcohol waste liquid, etc., to inhibit reproduction and development, improve Effects of photosynthesis and environmental pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

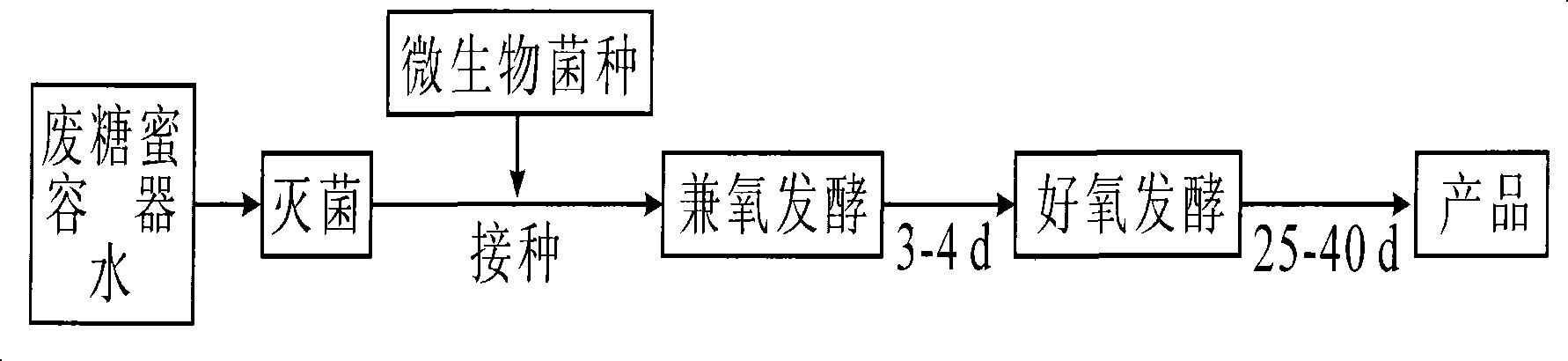

Method used

Image

Examples

Embodiment

[0013] Sterilize 100kg of waste molasses and 100kg of water and put them into a 200L sterilized fermenter. When the temperature drops below 35°C, inoculate 2kg of aerobic bacteria, yeast and actinomycete microbial strains in total, and stir with a sterilized wooden stick. uniform. At the same time, 3 layers of gauze were covered at the mouth of the fermenter for cultivation and fermentation. Beginning on the 4th day of fermentation, it is aerated every day (morning and afternoon respectively 30min), produces strong wine aroma until the 26th day and stops intermittent aeration. At this point, the fermentation production of biological foliar fertilizer is basically over.

[0014] The product was sprayed on the Guixiang 22 tea trees with 300 times water before and after the Spring Festival in a tea farm in Guilin, and sprayed every 15 days or so during the tea picking period. The output of one-bud one-leaf Guyu tea and Qingming tea increased by 15% and 23% respectively. The com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com