Method for preparing 2-phenylamino-6-dibutylamino-3-methyl fluoran

A technology of dibutylamino and methylfluorane, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of long-term low yield and achieve the effect of reducing consumption, cost and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

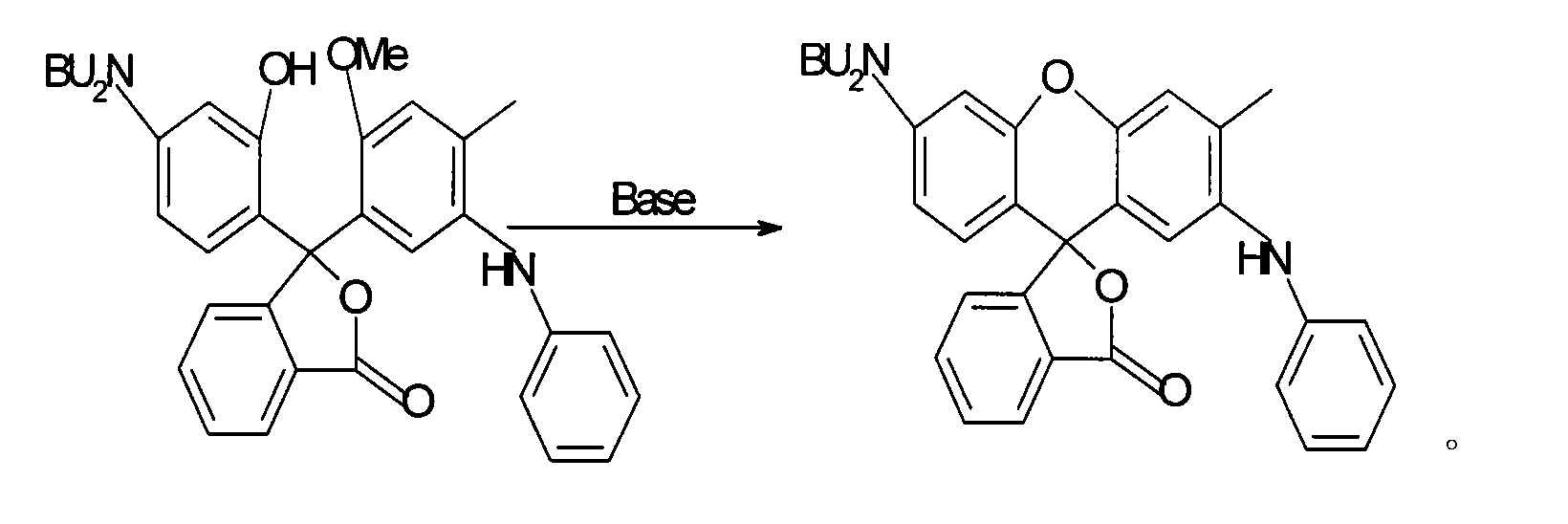

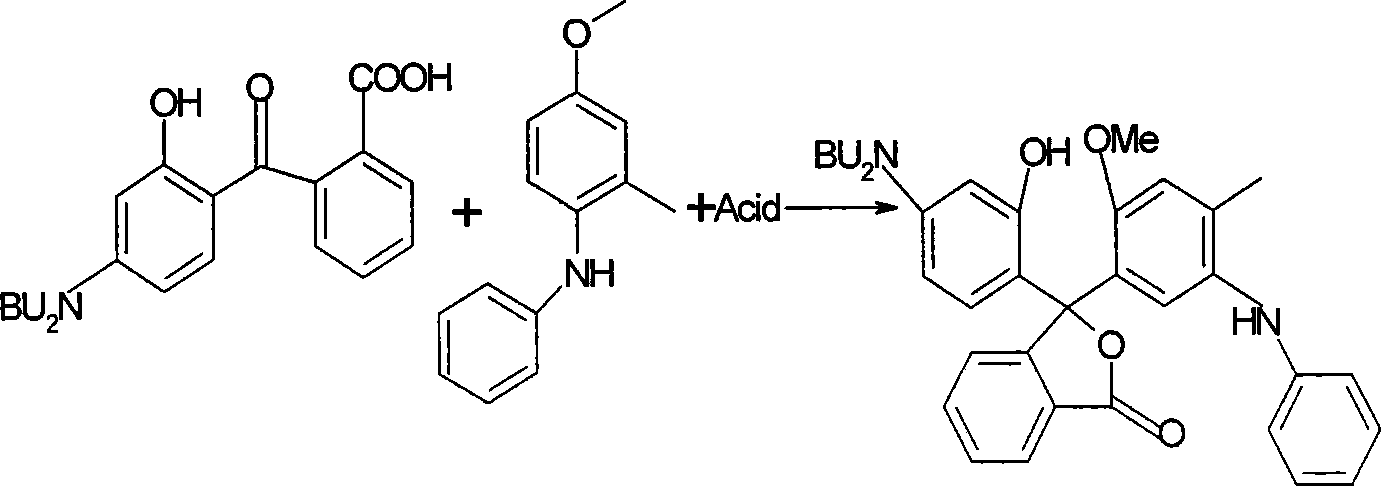

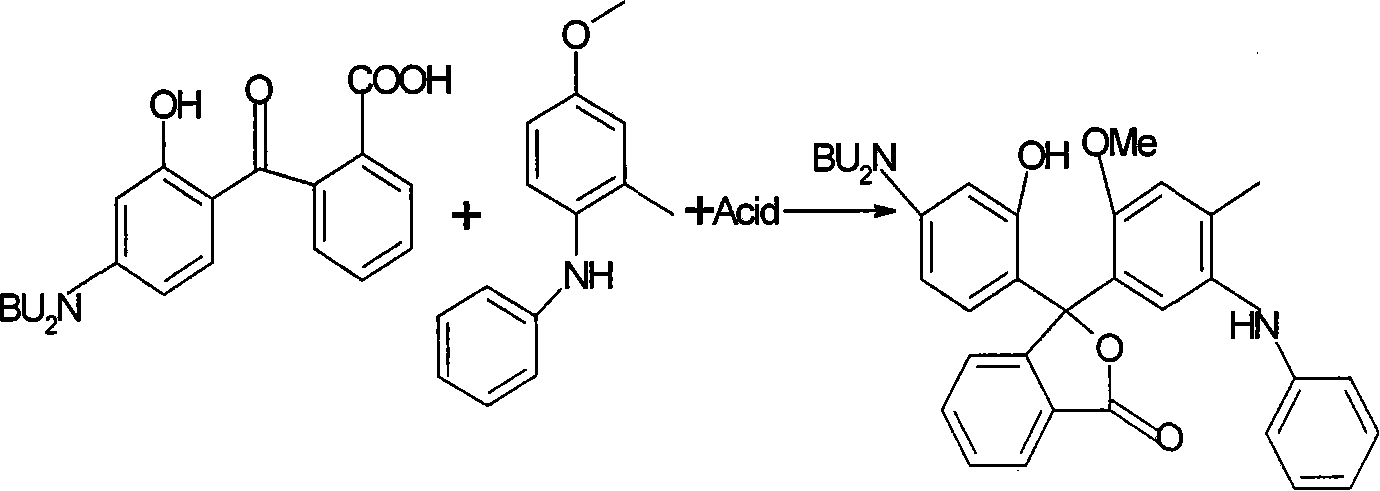

Method used

Image

Examples

Embodiment 1

[0015] Add 170g of 93% sulfuric acid into a 500ml reactor, slowly add 36.9g of 4-dibutylamino ketoacid (BBA) under stirring, finish adding in about 1 hour, wait until it is completely dissolved, then slowly add Add 21.3g of 2-methyl-4-methoxydiphenylamine (MMD) in 2-3 hours. The temperature of the whole process is controlled between 10-20°C, and the temperature is kept for 5-8 hours. Poured into a large amount of ice water, a large amount of solid matter was precipitated, filtered and washed to obtain a solid condensate. Add the condensate to a 1000ml reactor, add 50ml of toluene, 120ml of water, and then dropwise add 30% sodium hydroxide to keep the solution strongly alkaline at pH > 10, heat up and reflux for 2 to 4 hours, cool down to 20°C and crystallize and suction filter , washed and dried to obtain 42.5g of product, yield 79.6%, HPLC>99.5%, melting point: 183-183.5°C.

Embodiment 2

[0017] Add 170g of 96% sulfuric acid into a 500ml reactor, slowly add 36.9g of 4-dibutylamino ketoacid (BBA) under stirring, finish adding in about 1 hour, wait for it to completely dissolve, then slowly add Add 21.3g of 2-methyl-4-methoxydiphenylamine (MMD) in 2-3 hours. The temperature of the whole process is controlled between 10-20°C, and the temperature is kept for 5-8 hours. Poured into a large amount of ice water, a large amount of solid matter was precipitated, filtered and washed to obtain a solid condensate. Add the condensate to a 1000ml reactor, add 50ml of toluene, 120ml of water, and then dropwise add 30% sodium hydroxide to keep the solution strongly alkaline at pH > 10, heat up and reflux for 2 to 4 hours, cool down to 20°C and crystallize and suction filter , washed and dried to obtain 50.06g of product, yield 83.95%, HPLC>99.5%, melting point: 183.9-184.5°C.

Embodiment 3

[0019] Add 170g of 98% sulfuric acid into a 500ml reactor, slowly add 36.9g of 4-dibutylamino ketoacid (BBA) under stirring, finish adding in about 1 hour, wait until it is completely dissolved, then slowly add Add 21.3g of 2-methyl-4-methoxydiphenylamine (MMD) in 2-3 hours. The temperature of the whole process is controlled between 10-20°C, and the temperature is kept for 5-8 hours. Poured into a large amount of ice water, a large amount of solid matter was precipitated, filtered and washed to obtain a solid condensate. Add the condensate to a 1000ml reactor, add 50ml of toluene, 120ml of water, and then dropwise add 30% sodium hydroxide to keep the solution strongly alkaline at pH > 10, heat up and reflux for 2 to 4 hours, cool down to 20°C and crystallize and suction filter , washed, and dried to obtain 43.2 g of the product, with a yield of 81%, HPLC>99.5%, and melting point: 183.4-184.1°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com