Denim pigment dyeing technique with laser modifying function

A paint dyeing and denim technology, applied in the field of textile technology, can solve the problems of poor rubbing fastness, low rubbing fastness, and inability to completely replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

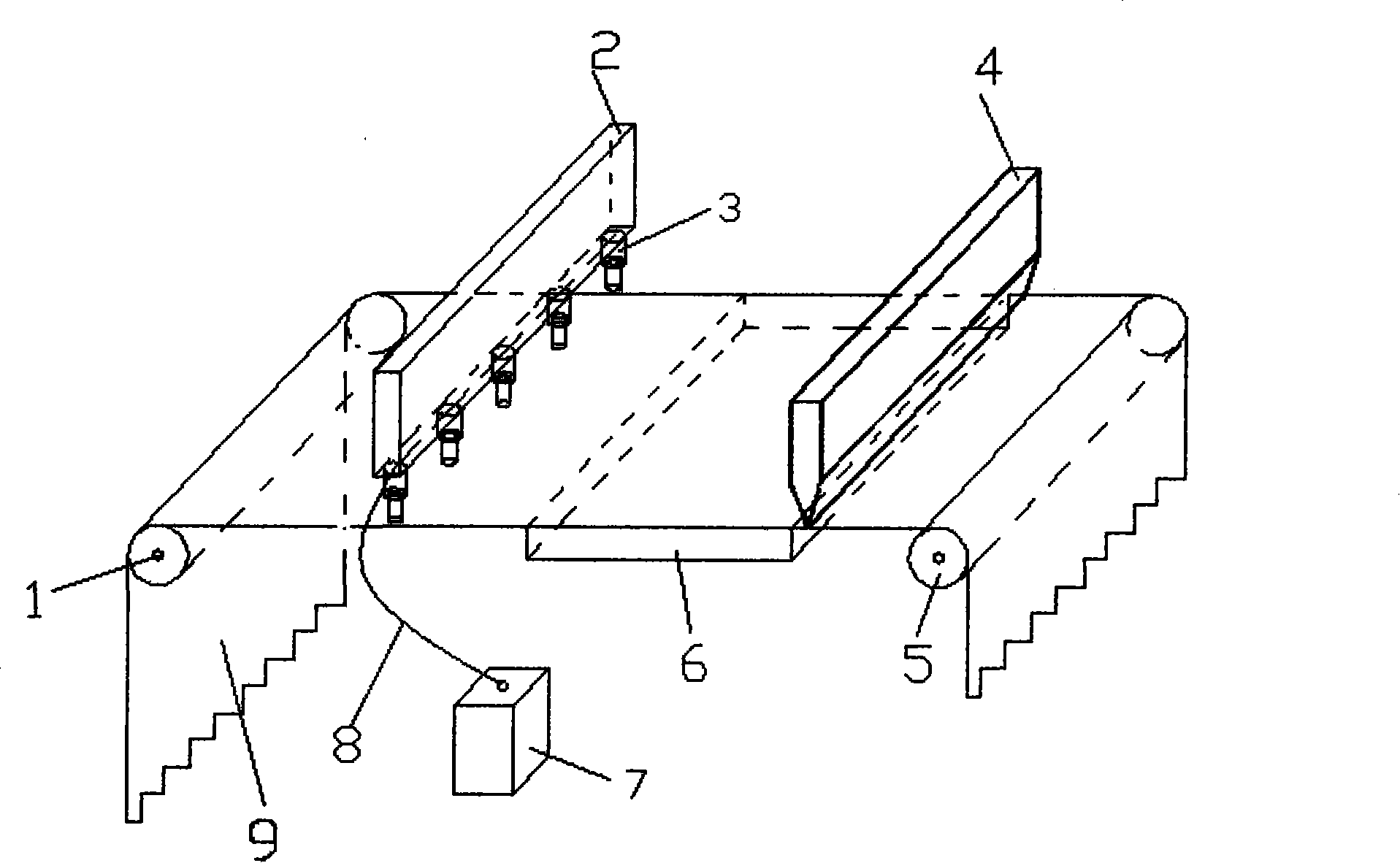

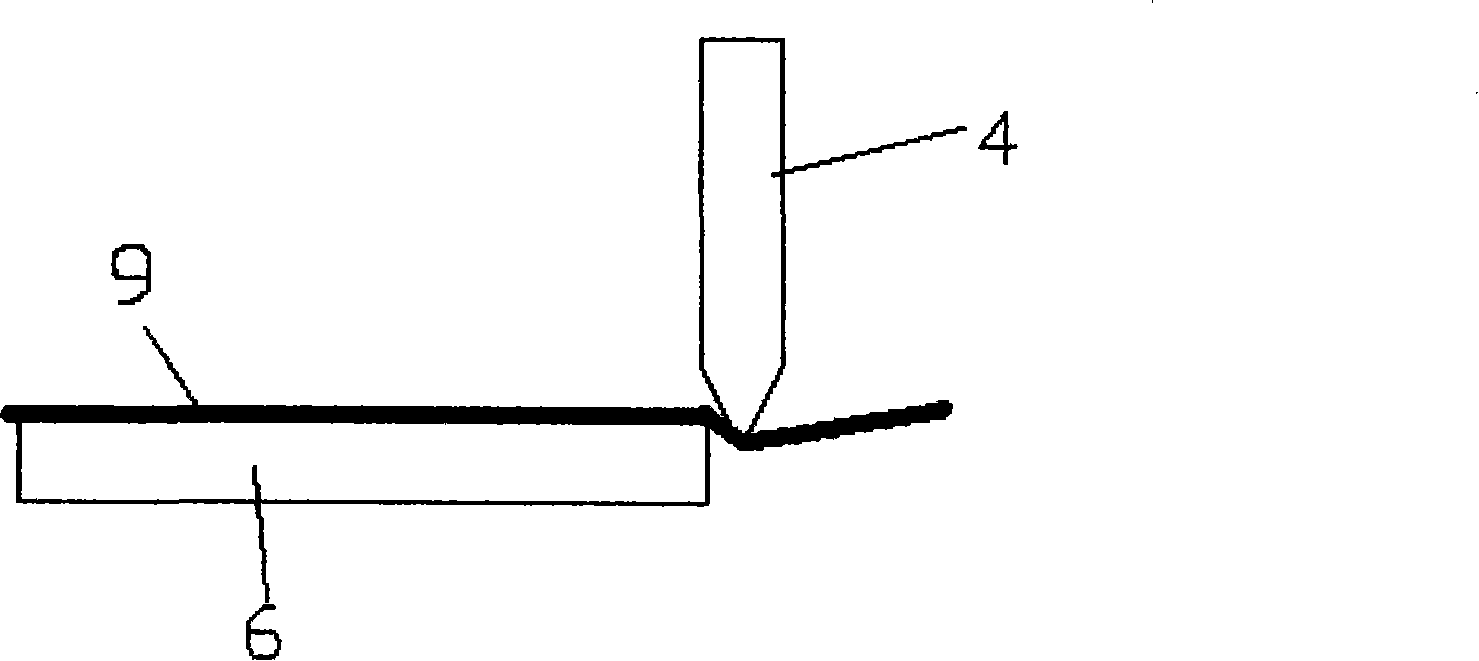

[0006] see Figure 1-2 , the specific embodiment adopts the following technical scheme: the denim 9 unwound from the cloth roll first passes through the cloth guide roller 1, and then enters the laser irradiation area for laser treatment, and the denim 9 after the laser treatment then enters the On the upper surface of the carrier board 6, the prepared coating is evenly applied to the denim 9 on the carrier board 6 afterwards, and the denim 9 with the coating then enters below the side knife 4, and the coating is on the side knife 4 and the cloth surface Under the extrusion, it penetrates below the cloth surface to achieve the purpose of dyeing. Finally, the dyed denim is exported to the next process by the cloth guide roller 5. The laser irradiation area of the present invention is lasered by a row of line light sources on the laser emitting head fixing plate 2. The emitting head 3 generates, and the input end of the line light source laser emitting head 3 and the output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com