Polishing apparatus

A technology for equipment and polishing surfaces, used in grinding/polishing equipment, metal processing equipment, machine tools for surface polishing, etc., which can solve problems such as production reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

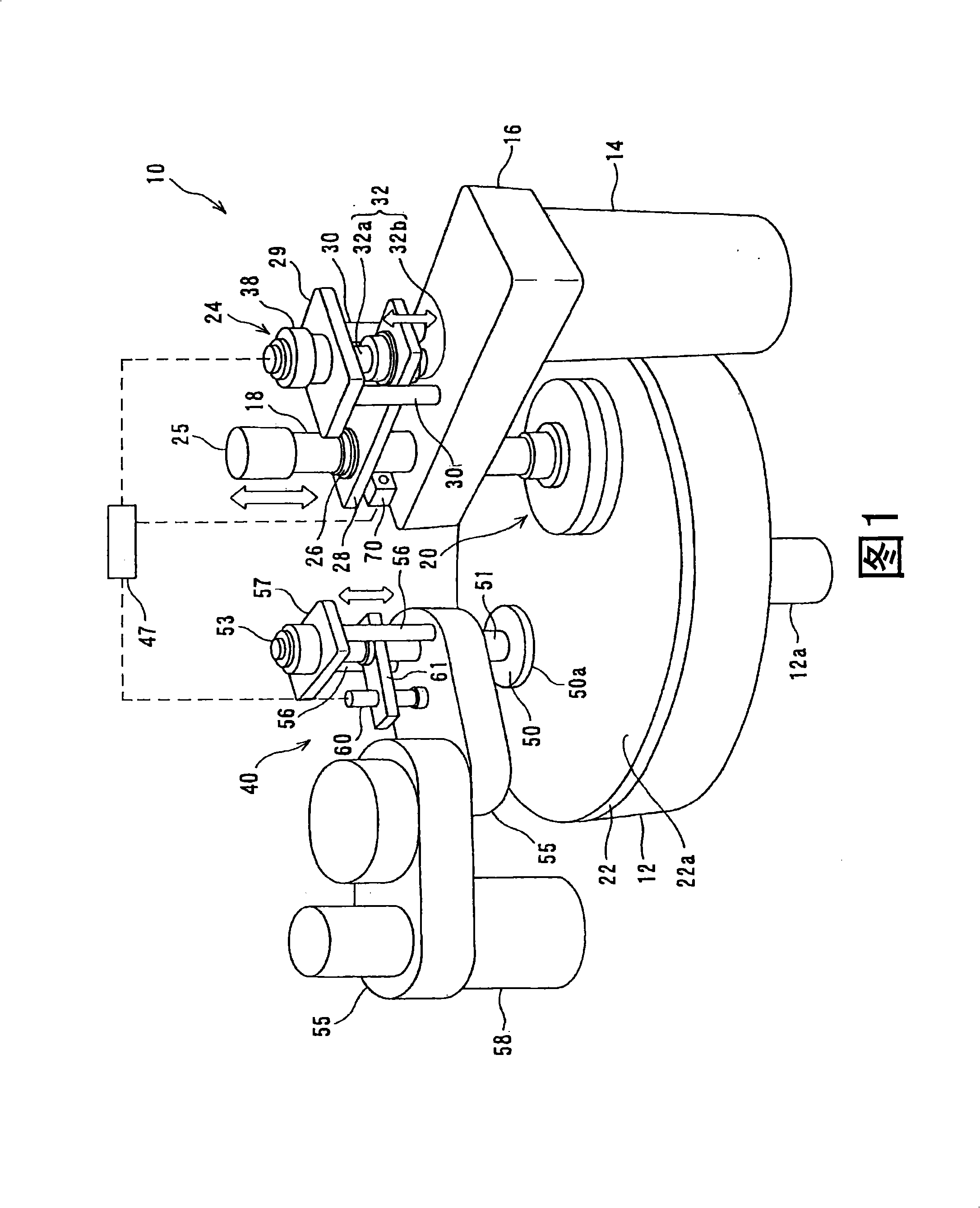

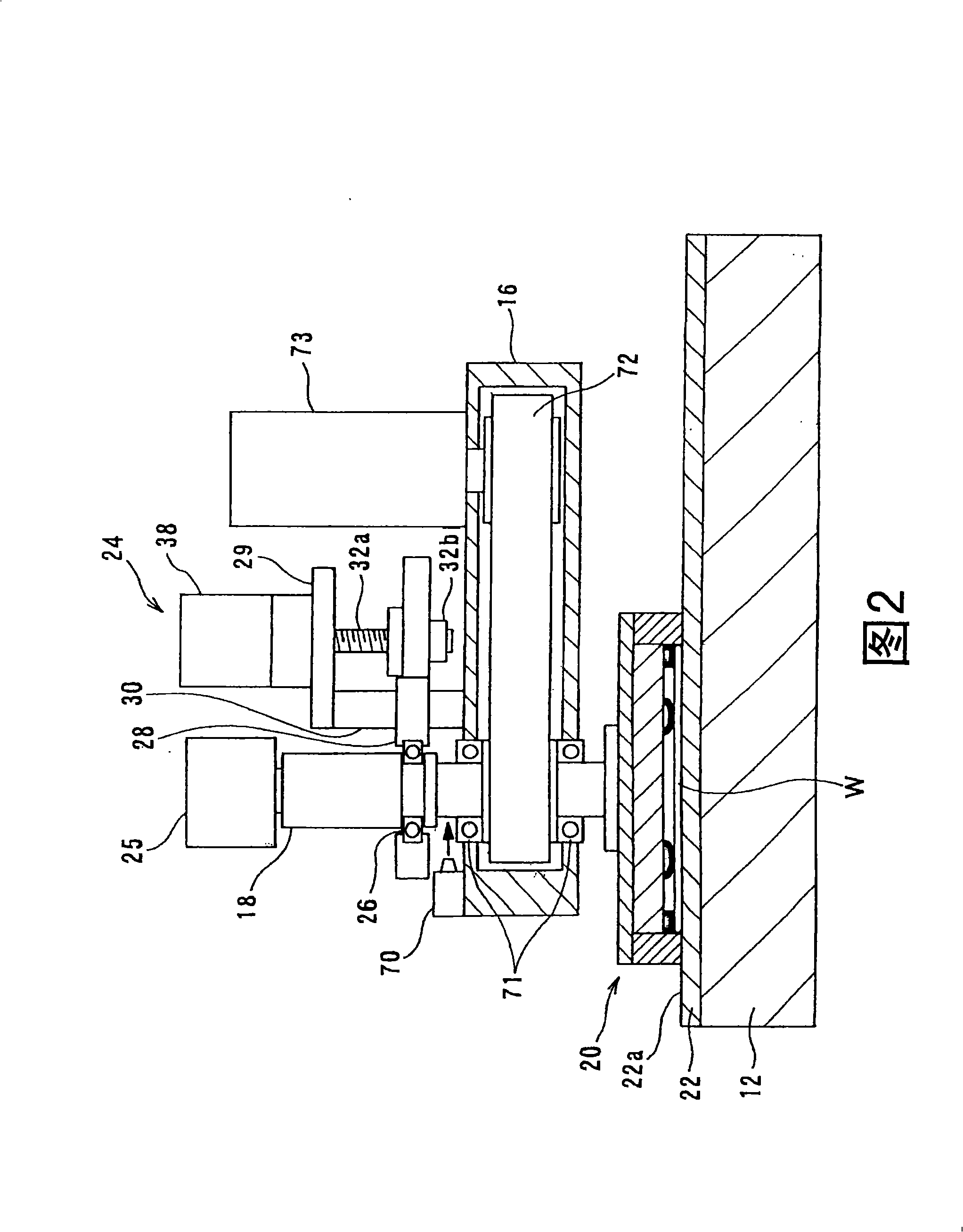

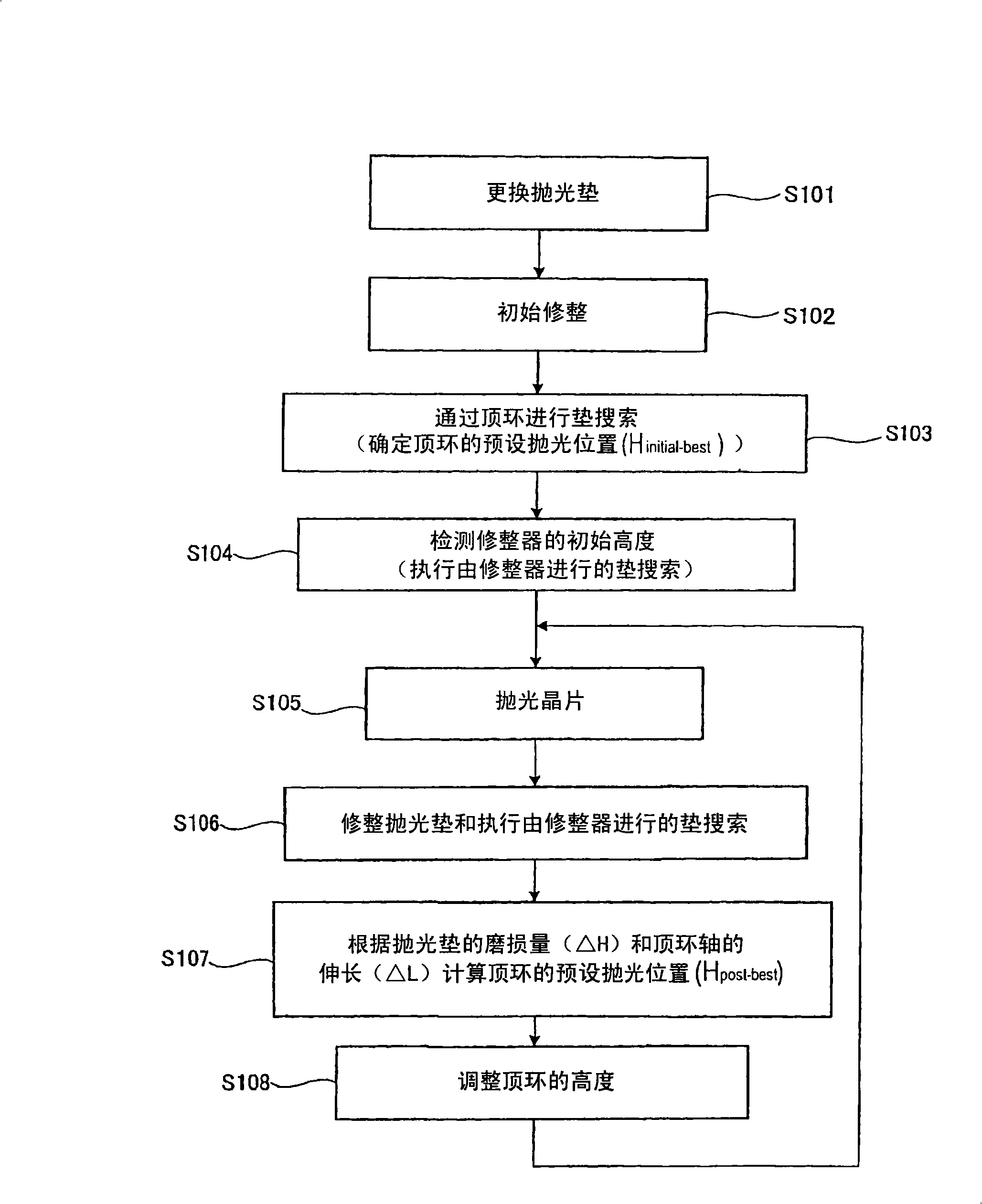

[0078] Referring to Figs. 1 to 18, an embodiment of the polishing apparatus of the present invention will be described below. In all the drawings, similar or identical components are denoted by similar or identical reference numerals, and they will not be described repeatedly in the following.

[0079] FIG. 1 is a schematic diagram showing a polishing apparatus 10 of a first embodiment of the present invention. As shown in Figure 1, polishing equipment 10 has polishing table 12, is connected to the top ring head 16 of supporting shaft 14 upper ends, is installed in the top ring shaft 18 on top ring head 16 free ends, is connected to the top ring of top ring shaft 18 bottoms 20. In the illustrated embodiment, the top ring 20 is a substantially circular plate. The top ring shaft 18 is connected to the top ring rotating motor through connecting means such as a timing belt, so that the top ring shaft 18 can rotate. However, in FIG. 1, the top ring rotating motor, the timing bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com