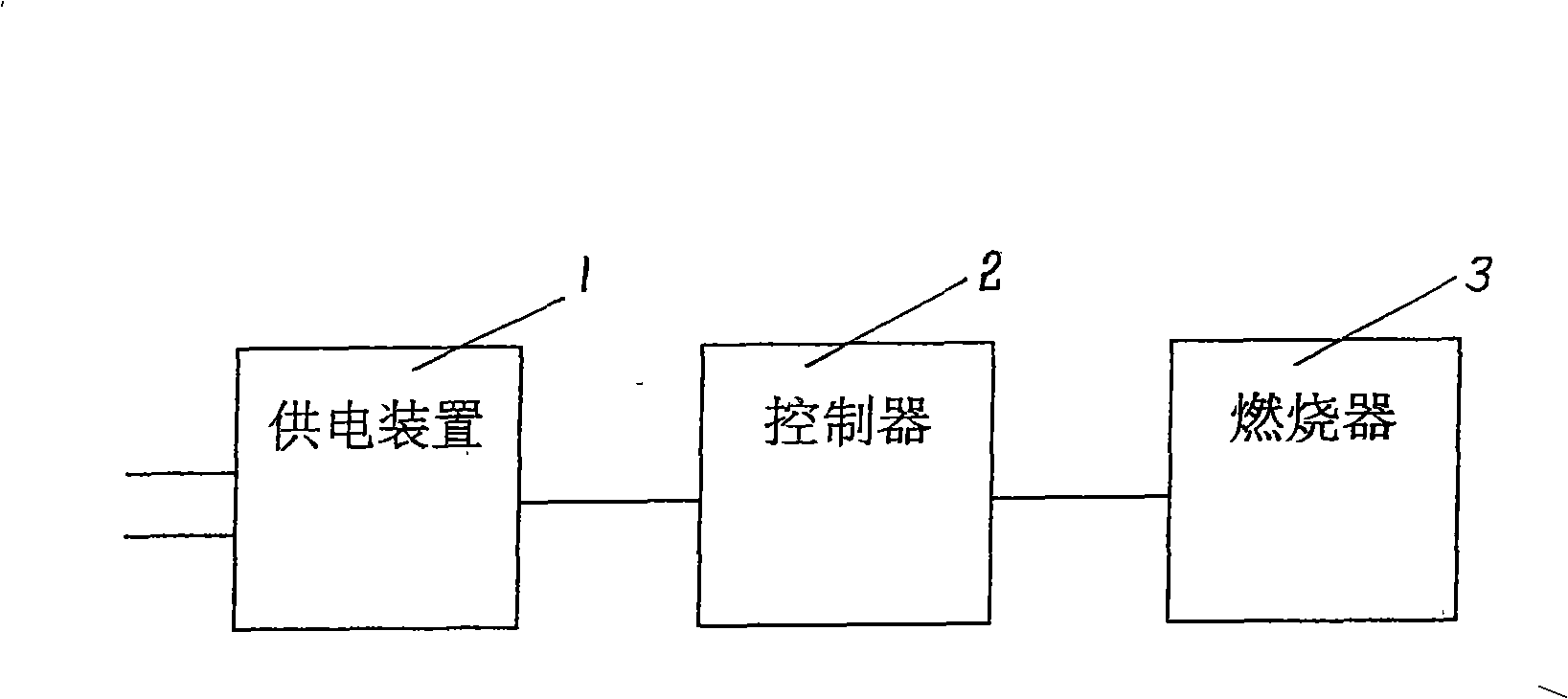

Electric-control vertical diesel oil combustion apparatus

A technology for combustion devices and power supply devices, applied in the direction of combustion control, circuit devices, battery circuit devices, etc., can solve the problems of large heat loss, no monitoring, uneven heating of the burner, etc., and achieve strong adaptability and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

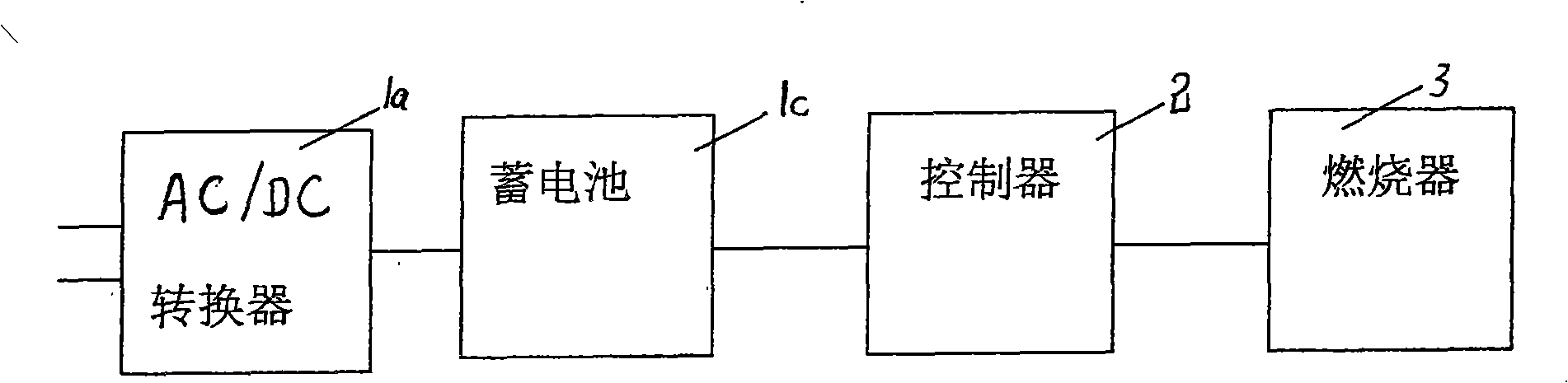

Embodiment approach 1

[0015] Embodiment 1, such as figure 2The converter of power supply device 1 adopts AC / DC converter 1a, one end is connected to 220V, 50HZ alternating current, the other end is connected to battery 1c, and the alternating current is converted into 13.8V direct current by the converter to store energy for battery 1c and supply power to the system , the controller 2 includes a control board 4, a display panel 5 and an adjustment knob 6, the control board 4 is composed of hardware and software, the hardware includes a control module with MCU as the core, the software is written into the MCU by online programming, and the display panel 5 To display the working status of the combustion device, the adjustment knob 6 is provided with three commands of power on, fire adjustment and shutdown, and the display panel 5 and the adjustment knob 6 together form a man-machine interface; the display panel 5 is provided with a work accumulation time mark and a lock alarm symbol, fire indicator,...

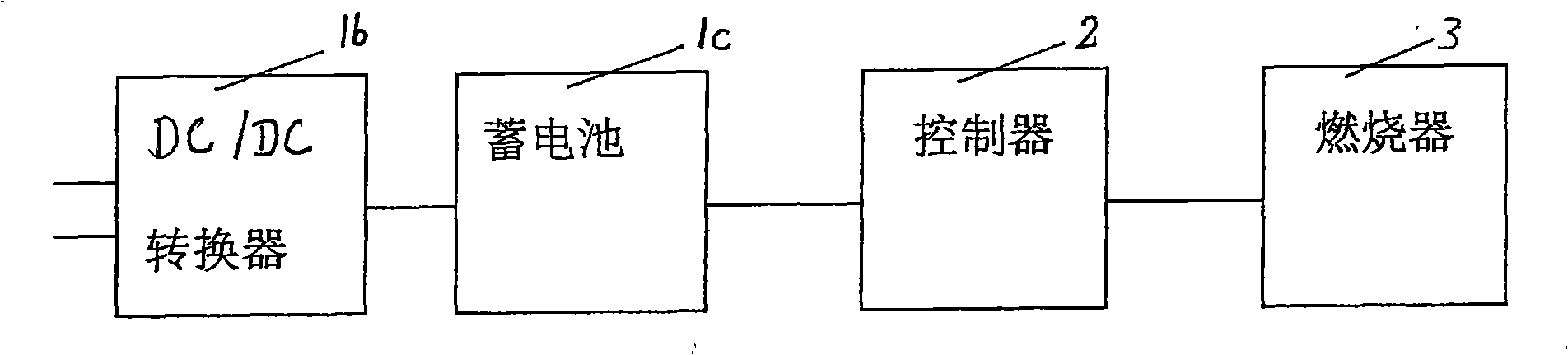

Embodiment approach 2

[0016] Implementation mode two, such as image 3 , the converter of the power supply device 1 adopts a DC / DC converter 1b, one end is connected to a 36V direct current, and the other end is connected to a battery 1c, after being converted to 13.8V, it stores energy for the battery 1c and supplies power to the system. When there is an external power supply, the converter turns it into low-voltage direct current to charge the battery, and at the same time supply power to the combustion system. When there is no external power supply, the battery supplies power to the combustion system, and the controller and the burner are connected by plugging. The connection and working principle of the controller and the burner are the same as those in Embodiment 1.

Embodiment approach 3

[0017] Implementation mode three, such as Figure 4 The converter of the power supply device 1 includes an AC / DC converter 1a and a DC / DC converter 1b connected in parallel. One end of the AC / DC converter 1a is connected to 280V, 50HZ alternating current, and the other end is connected to the battery 1c. DC One end of the / DC converter 1b is connected to a 10V direct current, and the other end is connected to a storage battery 1c. According to the actual situation, you can arbitrarily choose AC or DC as the external power supply. When there is an external power supply, it will be converted into low-voltage direct current through the converter to charge the battery and supply power to the combustion system at the same time. When there is no external power supply, the battery will supply power to the combustion system. The controller and the burner are connected by plugging. The connection and working principle of the controller and the burner are the same as those in Embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com