Heat treatment device

A heat treatment device and heat treatment chamber technology, applied in lighting and heating equipment, furnace components, furnace types, etc., can solve problems such as high quality requirements, difficulty in meeting quality and characteristics, and glass substrate scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

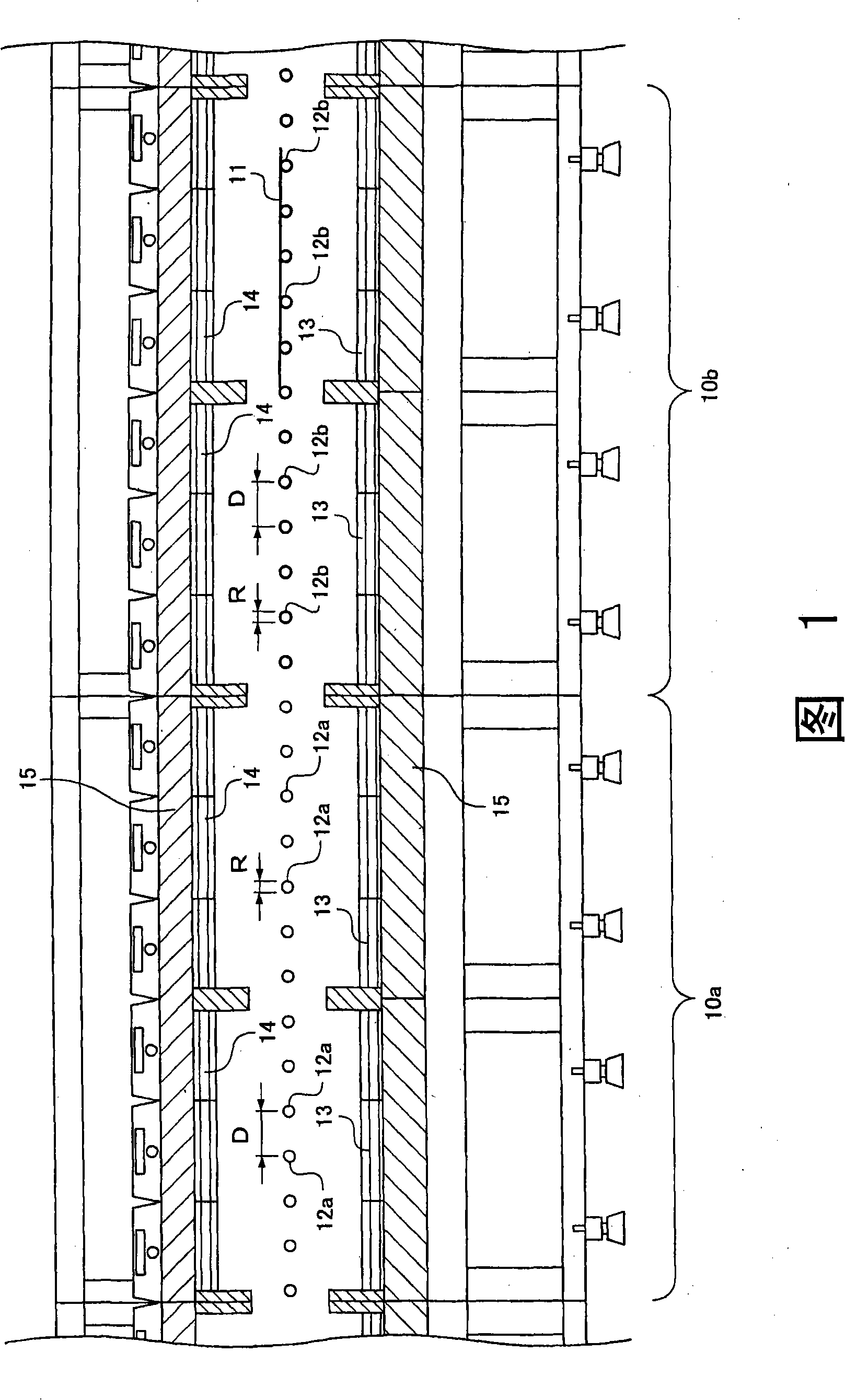

[0036] In the heat treatment apparatus with the structure shown in Fig. 1 and Fig. 6, use the upper and lower heaters of each heat treatment chamber, set the heat treatment condition that the maximum temperature reaches 600°C, and set the temperature rise condition of 15°C / minutes to heat the transferred glass substrate. The transport speed of the glass substrate was about 15 mm / s.

[0037] The roller table (hereinafter referred to as the first roller table) installed in the heat treatment chamber (hereinafter referred to as the first heat treatment chamber) where the maximum set temperature for heat treatment is less than 250°C is made of silicon carbide as the main component. Sintered body (SiC: about 78% by weight, Al 2 o 3 : about 12 wt%, SiO 2: about 8% by weight), the length is 1.8m, the outer diameter R is 38mm, and the distance D is 350mm. The proportion of the first heat treatment chamber with a temperature of less than 250° C. is about 10% of the total.

[0038...

Embodiment 2

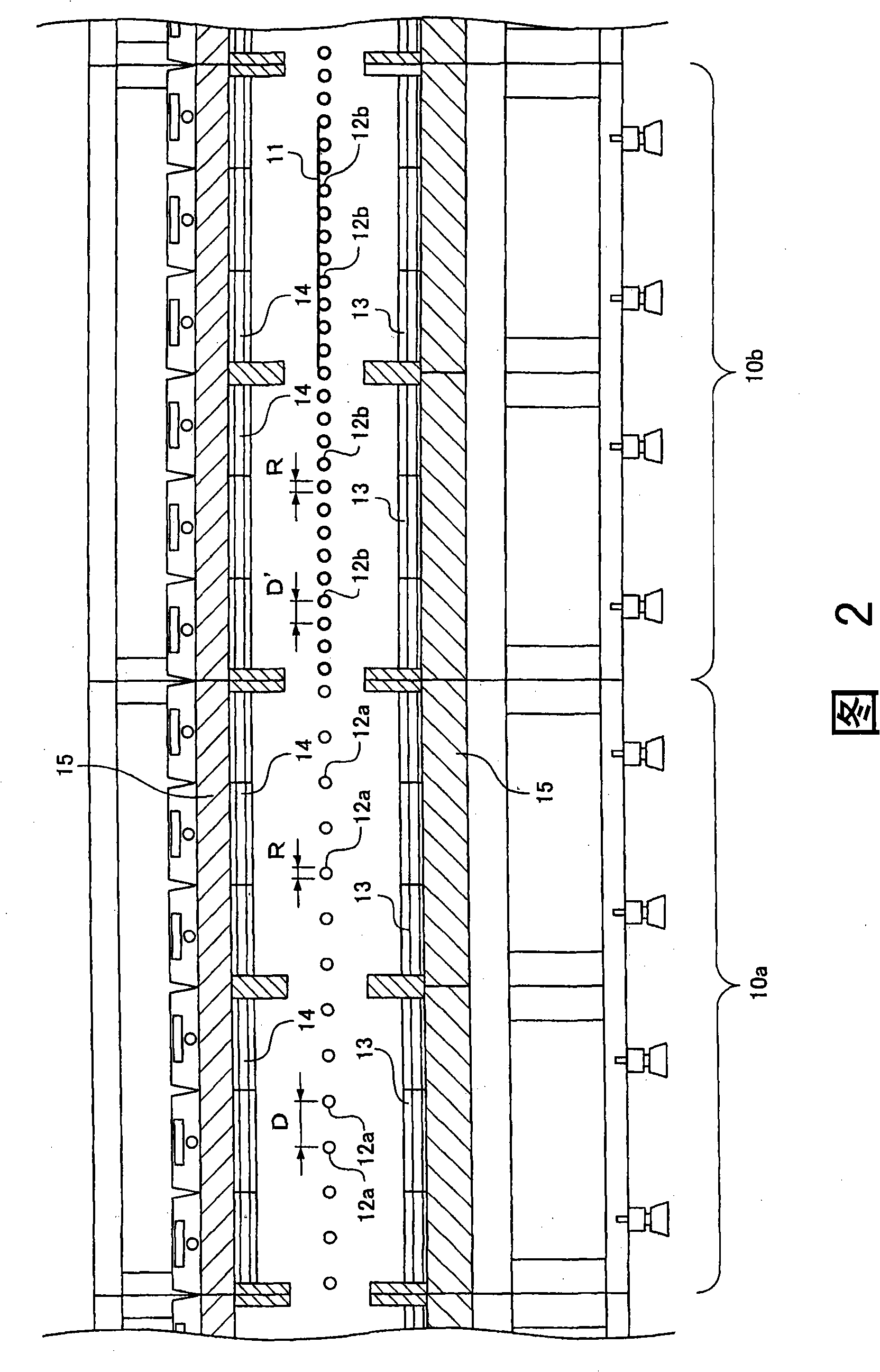

[0047] In the heat treatment apparatus with the structure shown in Fig. 2 and Fig. 6, as in Example 1, the heat treatment conditions are set so that the maximum temperature reaches 600°C, and as the temperature rise conditions to reach the maximum temperature, heat transfer is performed at 15°C / min. glass substrate.

[0048] The first roller table installed in the first heat treatment chamber with a maximum set temperature of less than 250°C is a sintered body mainly composed of silicon carbide, has the same composition as Example 1, has a length of 1.8m, and an outer diameter R is 38mm, install the interval D as 350mm.

[0049] The second roller table installed in the second heat treatment chamber with a maximum set temperature of 250°C or higher is a sintered body mainly composed of mullite, has the same composition as Example 1, has a length of 1.8m, and an outer diameter of R It is 38mm, however, install it with the interval D' as 150mm.

[0050] In this heat treatment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com