Beam neutralization in low-energy high-current ribbon-beam implanters

An electron and ion beam technology, which can be used in circuits, discharge tubes, electrical components, etc., to solve the problems of difficult capture and difficulty in space charge neutralization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

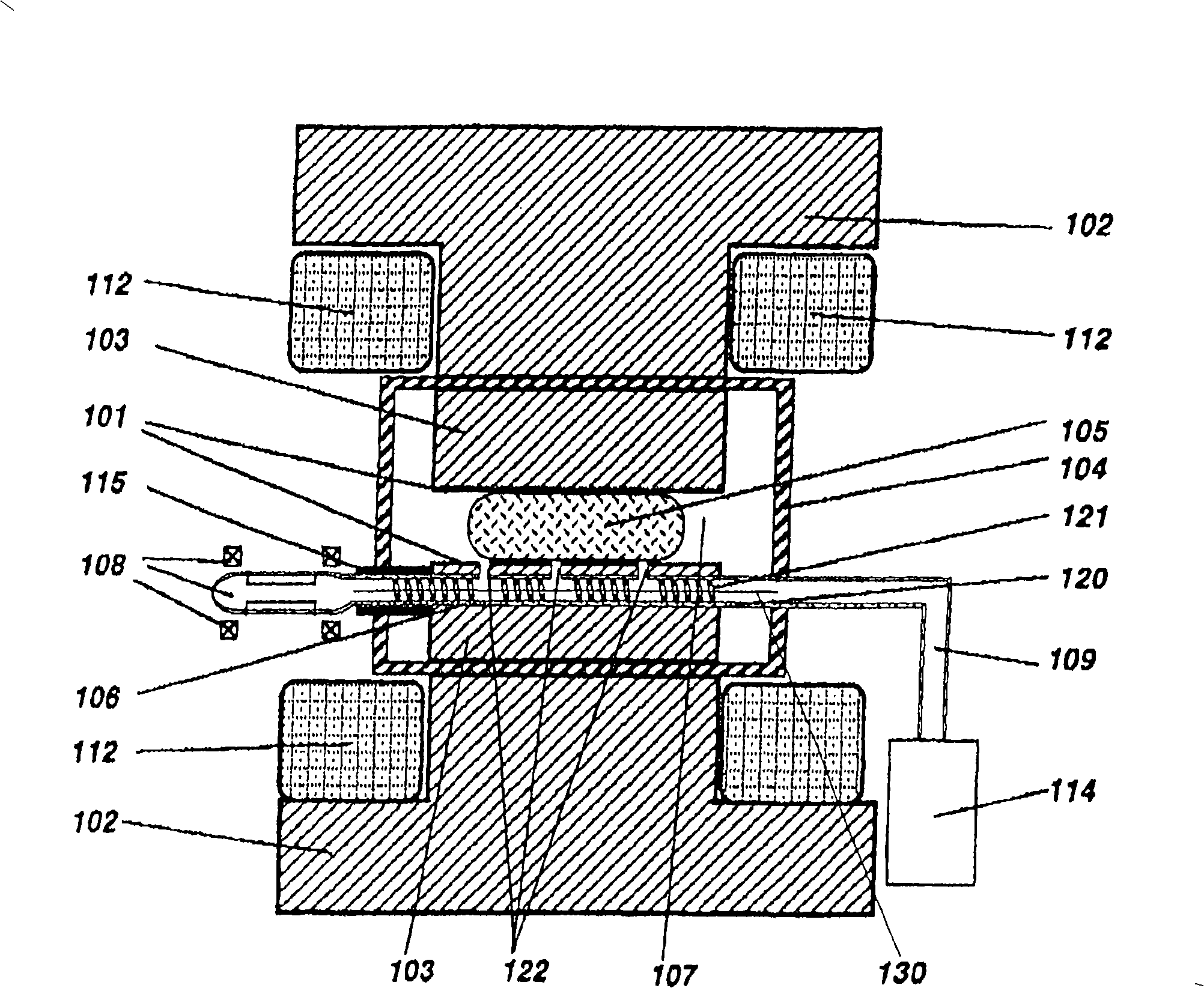

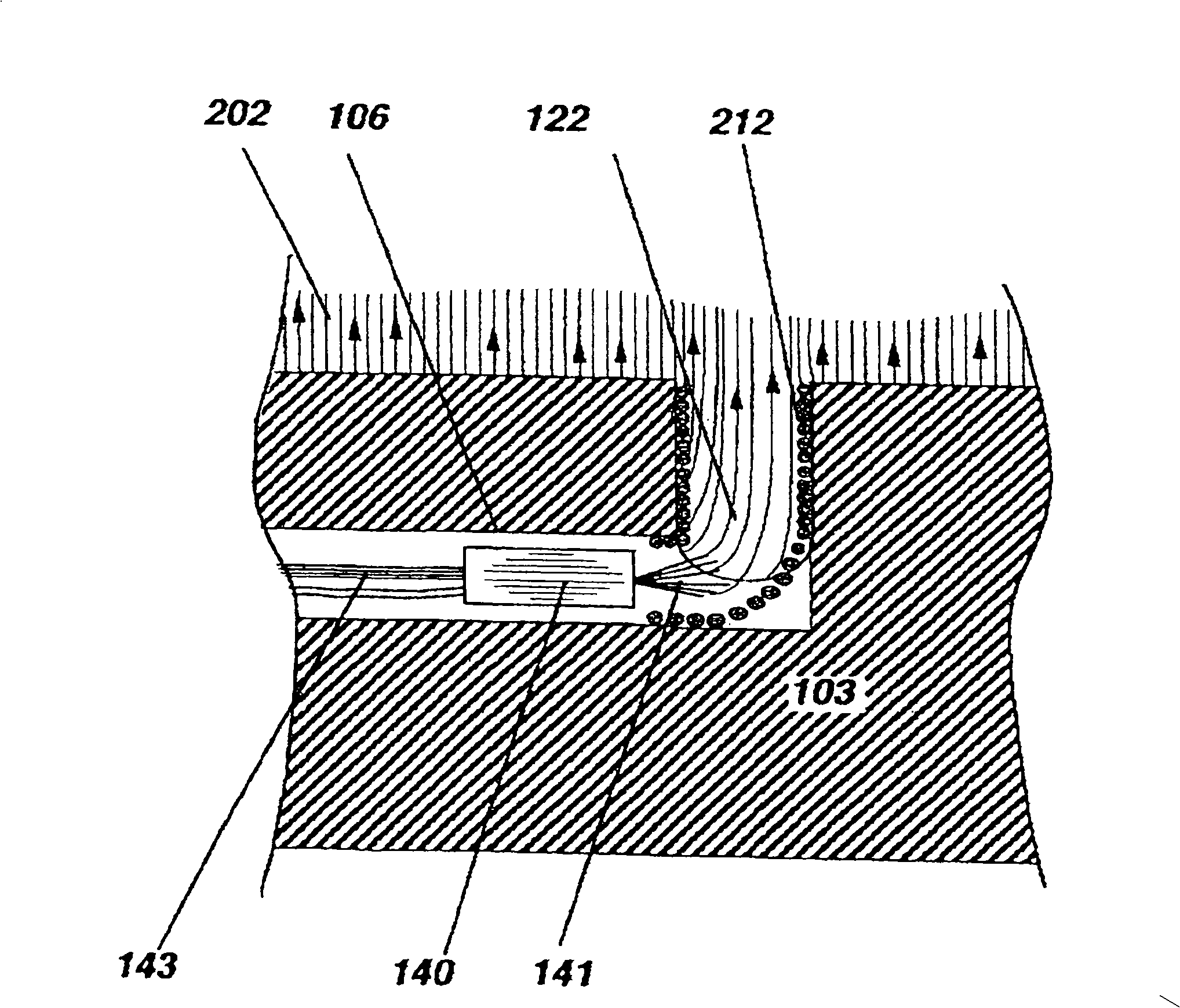

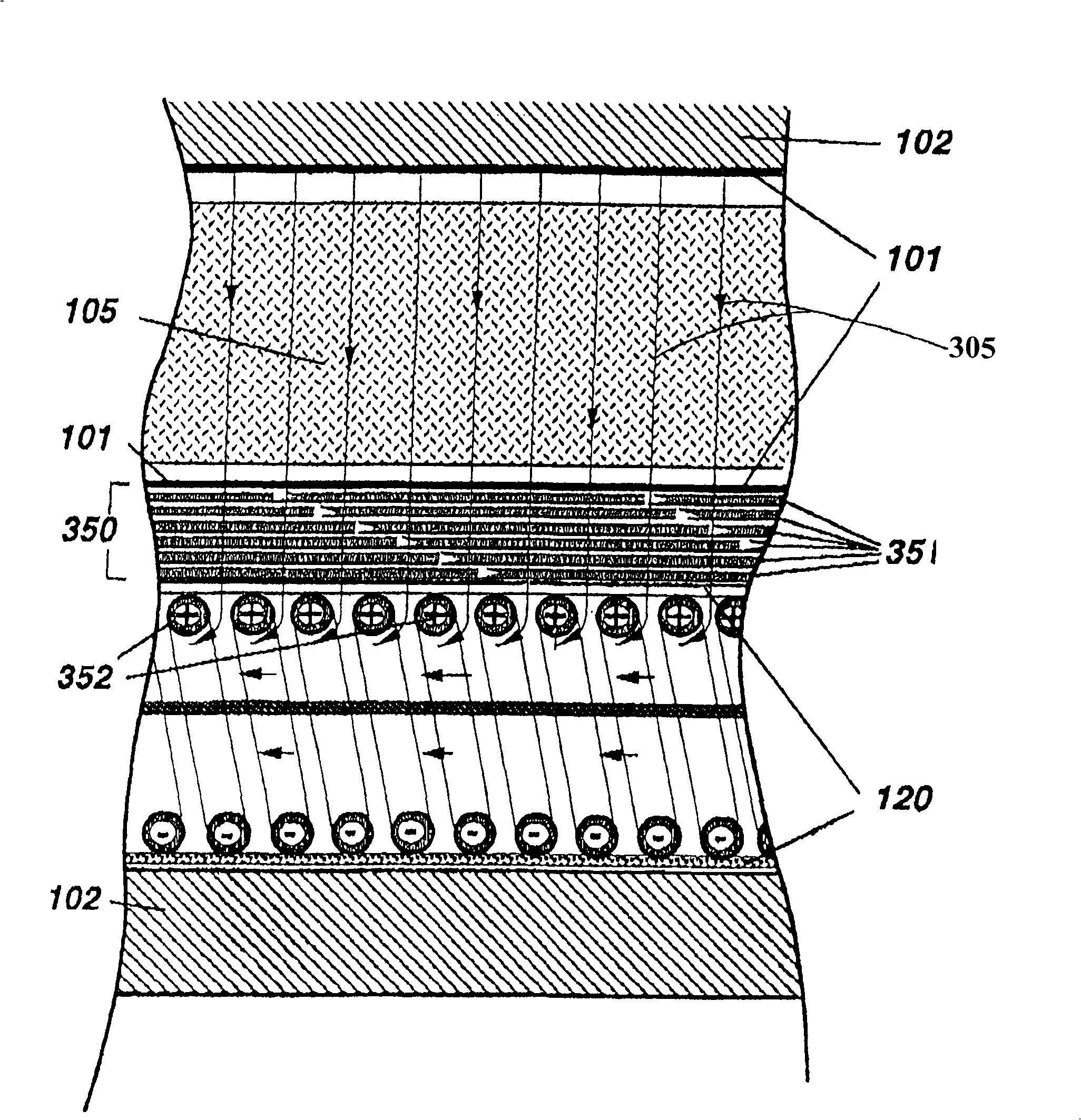

[0069] FIG. 1 illustrates a cross-section of a pole of a deflection magnet. In the preferred embodiment, the surface of the pole 103 is located within a vacuum chamber 104, although those skilled in the art will appreciate that the pole surface 101 may actually be part of an underlying magnetic return yoke 102. , not outside. A magnetic field is generated by the coil 112 . This allows the poles to be as close as needed to the ion beam trajectory 105 without wasting the distance of a wide vacuum-sealed enclosure that would require thick walls to withstand atmospheric pressure. A variable magnetic field can be actively introduced using surface windings described in Kenneth H. Purser and Norman L. Turner entitled "Broad Energy Range Ribbon Beam Collimation Using Variable Gradient Dipoles". Ion Beam Collimation Using a variable GradientDipole)" is described in detail in the companion patent application.

[0070] It can be seen that a hole 106 of suitable diameter is drilled thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com