Blending polymer shape memory material and preparation method thereof

A technology of blending polymers and memory materials, which is applied in the industrial and medical fields, and can solve problems such as limiting the development of industrialization, unclear mechanism of shape memory of blending polymer systems, pre-design and optimization of process conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 SBS / PCL Shape memory blends were prepared by compounding.

[0016] Styrene, butadiene, and styrene triblock copolymer (SBS) are selected as elastomers, and polycaprolactone (PCL) is selected as the crystalline polymer of inversion phase. The weight ratio of the two is SBS:PCL=3:7. The two components were mixed with a Brabender mixer for 10 min at 180°C at a speed of 60 min -1 . Tablets were then pressed to produce tablet samples for testing. The sample details and shape memory properties are shown in Table 1.

[0017] Table 1SBS / PCL compounding sample details and shape memory properties

[0018]

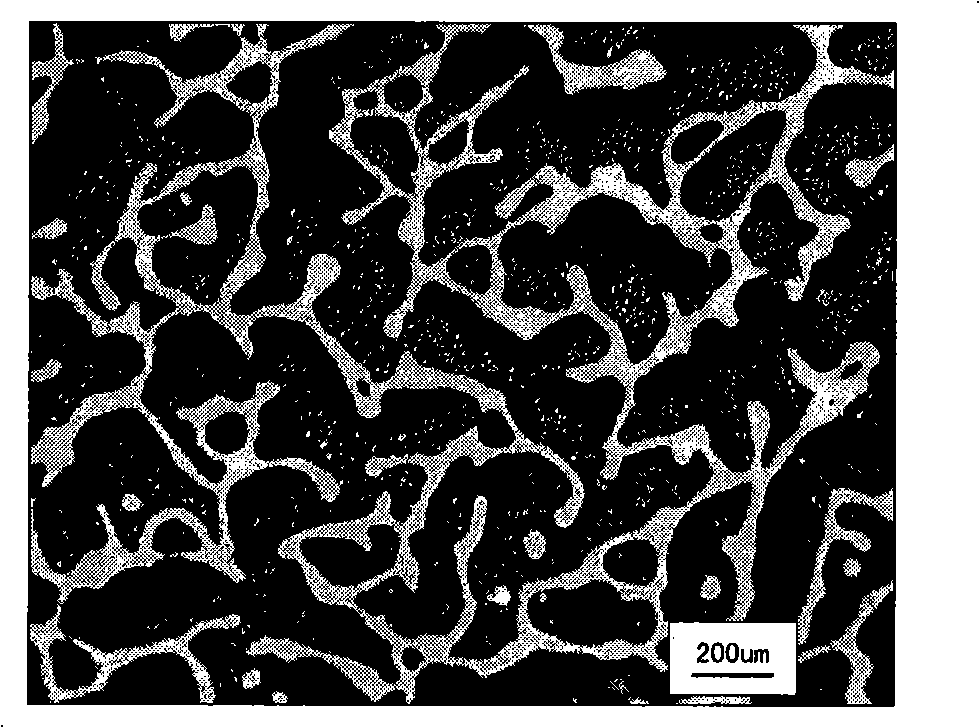

[0019] attached figure 1 Polarized microstructure photographs of the samples are given. The white area is the PCL phase, which is continuously distributed; the black area is the SBS phase, which belongs to the obvious matrix phase. The SBS of the matrix phase provides good tensile properties and resilience, making the blends have good shape recovery. The c...

Embodiment 2

[0020] Example 2SBS / PCL Shape memory blends were prepared by solution blending.

[0021] SBS and PCL were simultaneously dissolved in tetrahydrofuran solvent. The weight ratio of SBS and PCL was 50:50. The total solution concentration of SBS and PCL was 10 wt%. After a little heating and stirring to be completely dissolved, the solution is poured into a specific mold, and the tetrahydrofuran is volatilized under the heating of an infrared lamp. After the tetrahydrofuran has evaporated, a sample of a specific shape is obtained. This sample was pressed into a tablet for testing. Shown in Table 2 are the sample details and shape memory properties.

[0022] Table 2SBS / PCL solution blending sample details and shape memory properties

[0023]

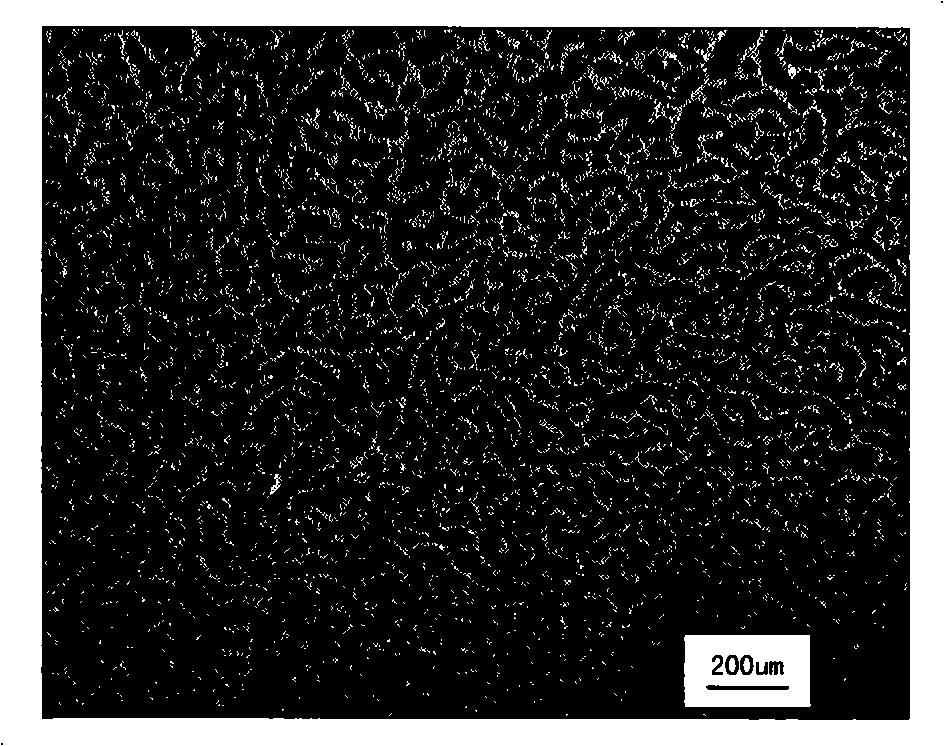

[0024] attached figure 2 Photographs of the polarized microstructure of the samples are given in . The white area is the PCL phase, and the black area is the SBS phase. The two phases show obvious bicontinuous phase distribution, ...

Embodiment 3

[0025] Example 3 Natural rubber / polylactic acid shape memory blend

[0026] The elastomer is selected from natural rubber after vulcanization, and the phase transition polymer is selected from amorphous polylactic acid (PLA). The weight ratio of the two is natural rubber:polylactic acid=5:5. The two components were mixed with a Brabender mixer for 10 min at 200°C, and the rotational speed was 60 min -1 . Tablets were then pressed to produce tablet samples for testing. The sample details and shape memory properties are shown in Table 3.

[0027] Table 3 Details and shape memory properties of natural rubber / polylactic acid (PLA) mixed samples

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com