Bacterium inoculation method and special-purpose ejecting type separating gun for the same

A bacterial inoculation and spraying technology, applied in the direction of bacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of complicated operation, inappropriate bacteria that are not resistant to high temperature, easy to cause pollution, etc., to achieve easy dispersion, Easy to operate and reduce the chance of bacterial loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A bacterial inoculation method, the method is to use the principle of the suction ear ball to uniformly spray the bacterial solution into the culture medium through the power of the instantaneously generated high-pressure gas.

Embodiment 2

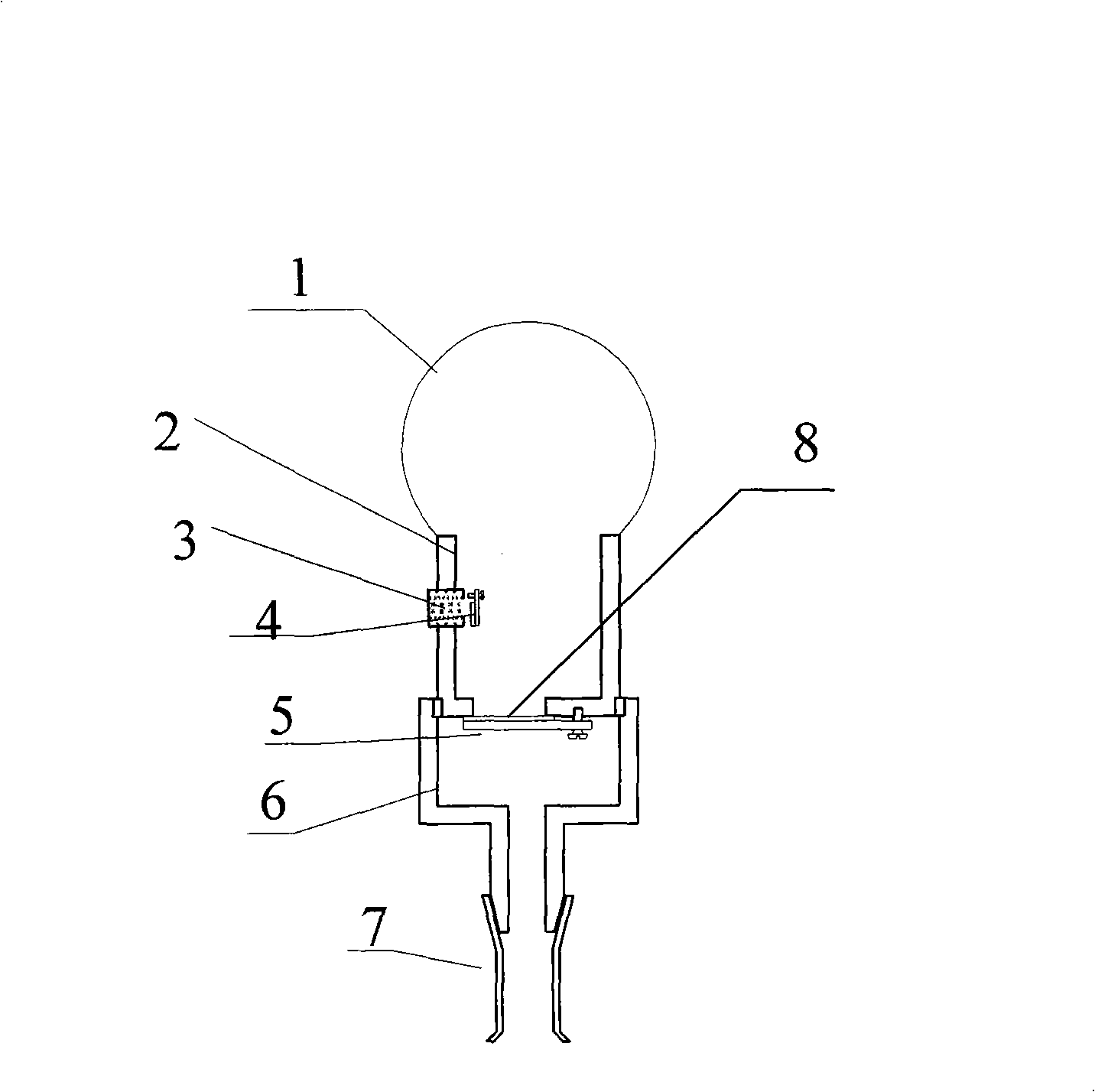

[0022] The following combination figure 1 A kind of jet type separation gun of the present invention is described in further detail, comprises a rubber ball 1 and nozzle 7, is characterized in that, described rubber ball 1 is connected with one end of connecting pipe 2 sealingly, and the other end of connecting pipe 2 is connected with One end of the connecting pipe 6 is sealed and connected, and the other end of the connecting pipe 6 is connected with the nozzle 7;

[0023] A gas filter 3 is connected to the side wall of the connecting pipe 2, and an air intake valve 4 is connected to the gas filter 3;

[0024] A hole 8 is provided at one end of the connecting pipe 2 connected to the connecting pipe 3 , and an outlet valve 5 is connected at a position corresponding to the hole 8 .

[0025] The intake valve 4 is a one-way valve.

[0026] The air outlet valve 5 is a one-way valve.

[0027] The other end of the nozzle 7 is a bell mouth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com