Micro- solid mode gyroscope

A micro-solid, modal technology, applied in the direction of gyroscopic effect for speed measurement, gyroscope/steering sensing equipment, measurement device, etc., can solve the problem of limited microfabrication performance of piezoelectric ceramics, limited material selectivity, and low feasibility. problems, to achieve the effect of increasing micromachinability, strong anti-vibration ability, and improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

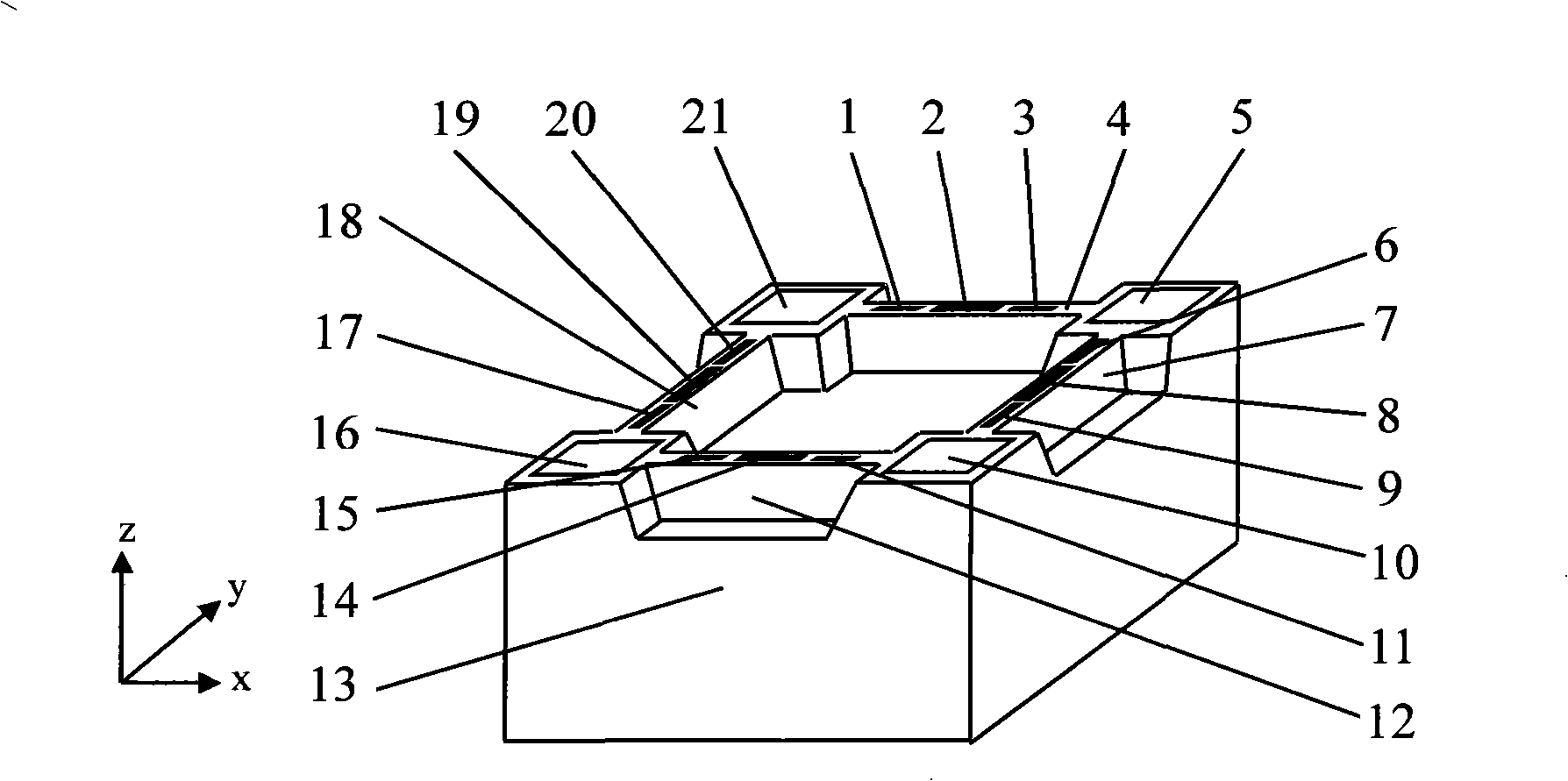

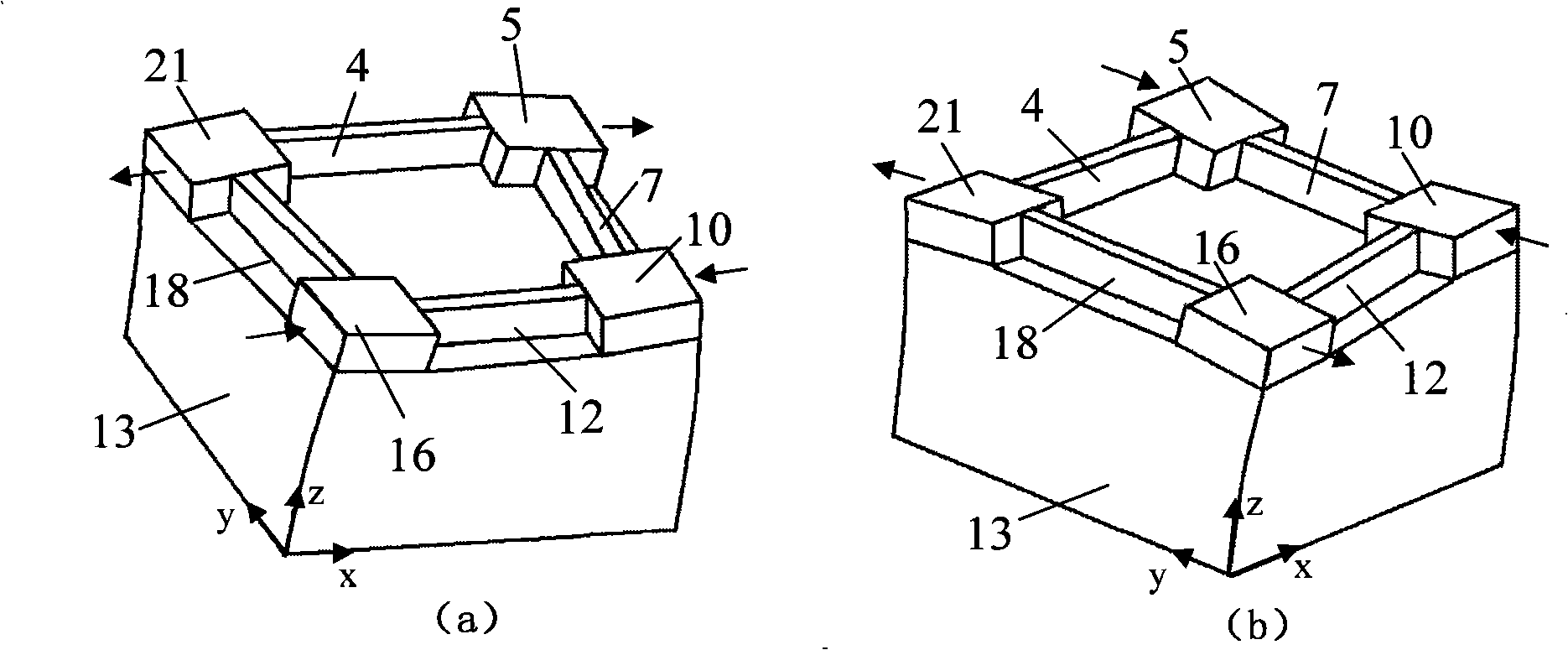

[0017] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

[0018] Such as figure 1 As shown, this embodiment includes: four pairs of piezoelectric control electrodes 1, 3, 6, 9, 11, 15, 17, 19, two piezoelectric sensing electrodes 2, 14, and two piezoelectric driving electrodes 8, 19 , four lumped masses 5, 10, 16, 21, four linear vibration enhancement structures 4, 7, 12, 18, and an elastic matrix 13.

[0019] The elastic base 13 is made of a material with good elasticity, such as metal, glass or polymer material. The linear vibration enhancing structures 4 , 7 , 12 , 18 are formed on the elastic base 13 by wet etching, and the linear v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com