Heavy caliber aspherical mirror checking system

An aspherical mirror and detection system technology, applied in measurement devices, testing optical properties, instruments, etc., can solve problems such as difficulty in adjustment, and achieve the effect of simplifying the manufacturing process, ensuring reliability, and avoiding mask alignment errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

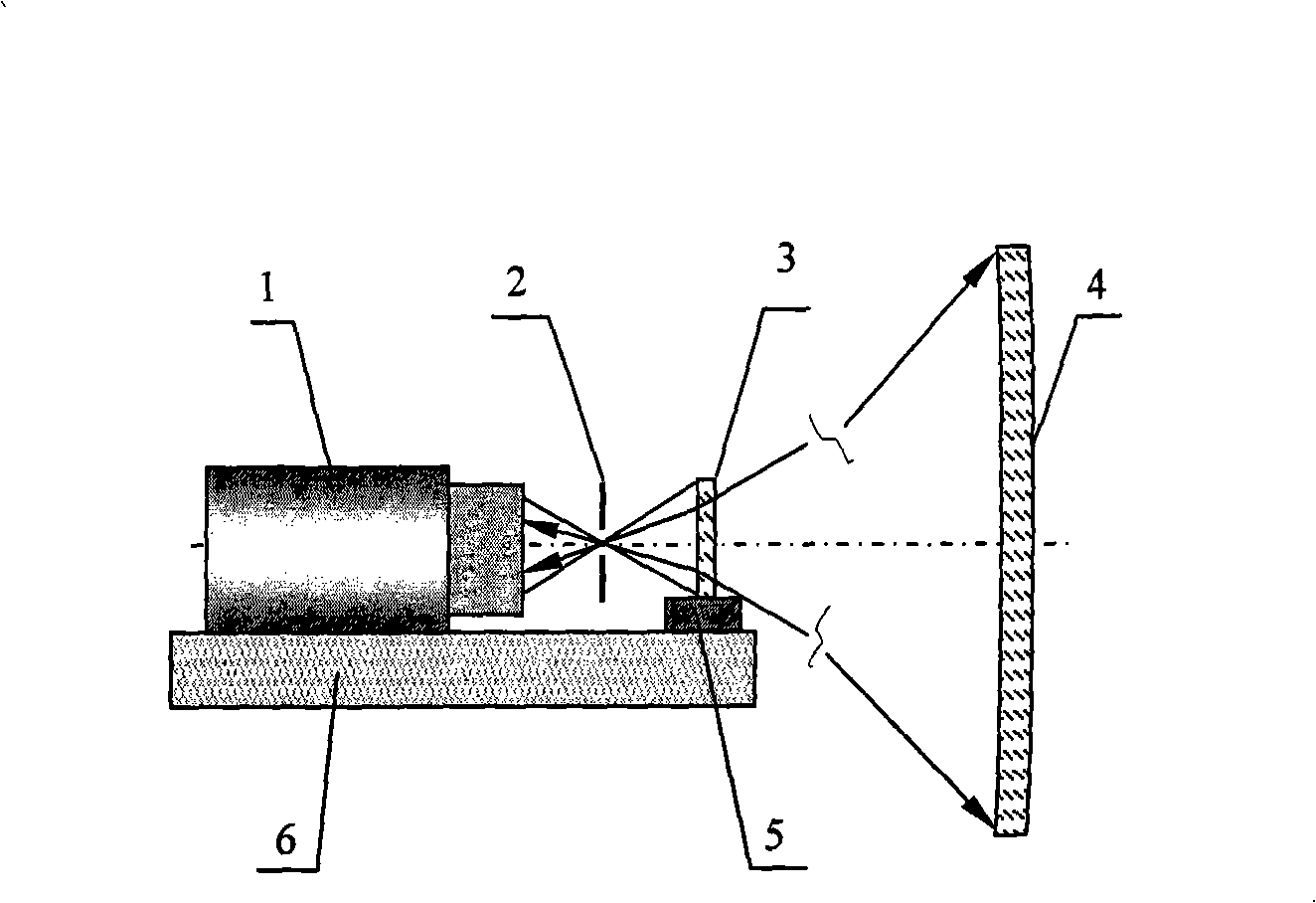

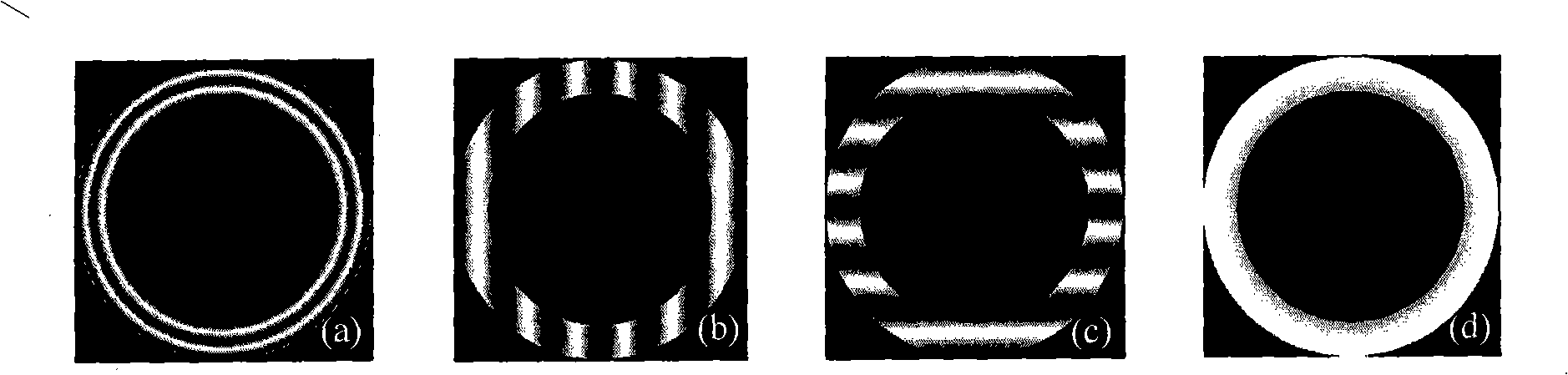

[0019] Such as figure 1 As shown, a large-diameter aspheric mirror detection system in this embodiment consists of a Fizeau type interferometer 1, a pinhole filter 2, a double calculation hologram 3, a measured aspheric mirror 4, a small five-dimensional adjustment frame 5 and a large The five-dimensional adjustment frame 6 is composed; the double calculation hologram 3 is composed of two parts: the main hologram and the alignment hologram, both of which are phase type calculation holograms and must be concentric; the double calculation hologram 3 is fixed On the small five-dimensional adjustment frame 5, place the Fizeau interferometer 1 and the pinhole filter 2 on the large five-dimensional adjustment frame 6, and adjust the double calculation hologram 3 relative to the measured aspheric mirror through the large five-dimensional adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com