Char /char compound material antioxygenic property test device

A technology of carbon composite materials and anti-oxidation properties, which is applied in the direction of measuring devices, analyzing materials, and weighing by removing certain components, can solve the problem of inability to measure the weight loss of carbon/carbon composite materials online, long measurement intervals, and only It can manually record and other problems to achieve the effect of short measurement interval, improved measurement accuracy, and convenient and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

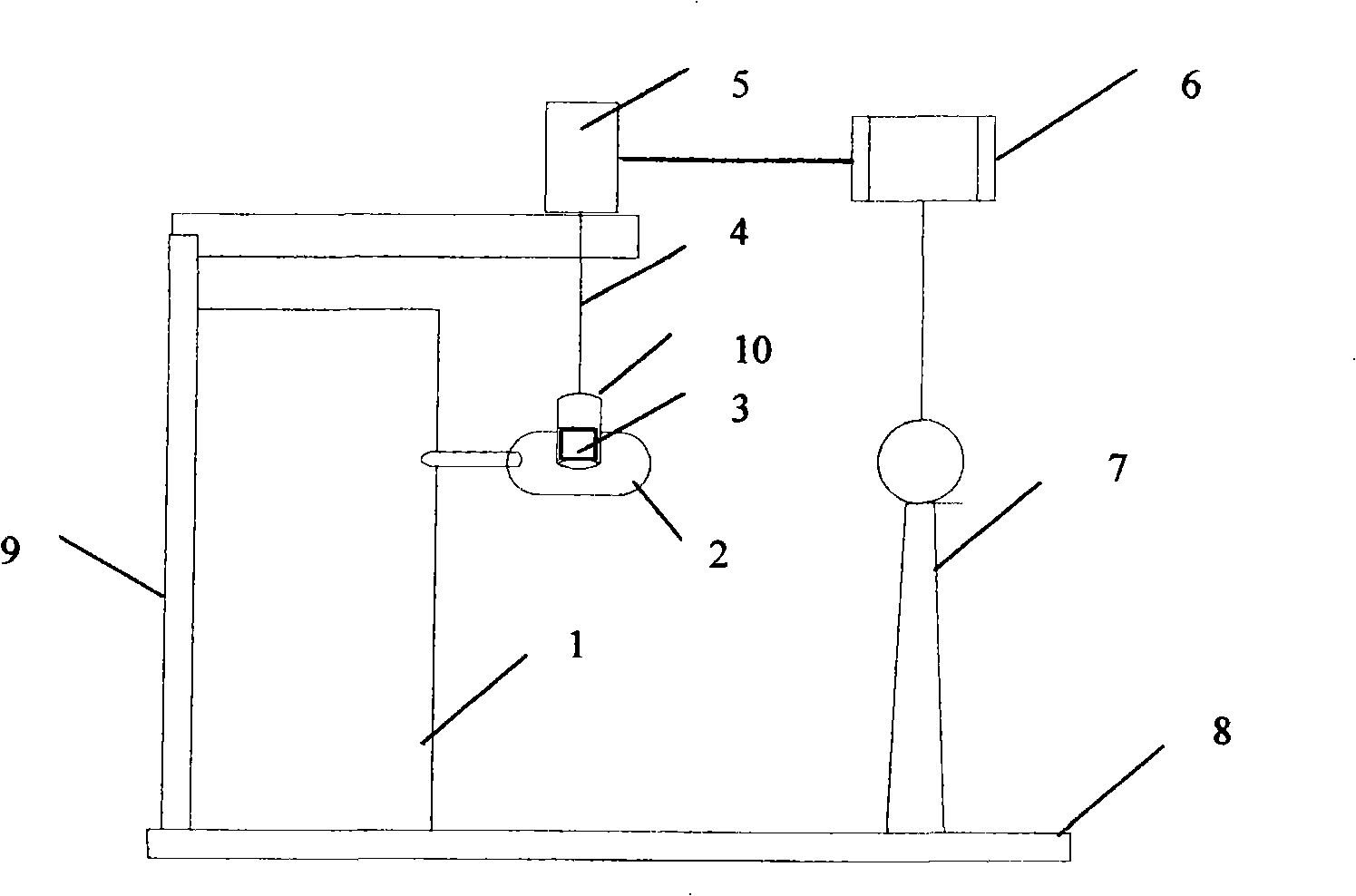

[0012] The present invention will be described in further detail below. see figure 1 , a carbon / carbon composite material oxidation resistance testing device, comprising a platform 8, a support 9 fixed on the platform 8, a heating device installed on the support 9, a temperature measuring device 7 fixed on the platform and a measuring balance 5, characterized in that,

[0013] (1) said heating device is made of an intermediate frequency induction power supply 1 with an induction coil 2;

[0014] (2) said measuring balance 5 is an electronic analytical balance, it is fixed on the support 9, is positioned at the direct top of the induction coil 2, has a platinum-rhodium wire 4, and its lower end is connected with a hanging crossbeam of a testing crucible 10, The carbon / carbon composite material sample to be tested is placed in the test crucible 10, the test crucible 10 is located in the center hole of the induction coil 2, and the upper end of the platinum rhodium wire 4 is ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com