Exhaust device, substrate processing device incorporating same and exhaust method

A substrate processing device, exhaust device technology, applied in electrical components, climate sustainability, greenhouse gas capture, etc., can solve problems such as obstruction of exhaust gas flow, valve malfunction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] According to Figure 1- Figure 11 Preferred embodiments of the present invention will be described in detail. Embodiments of the present invention can be changed in various forms, and the scope of the present invention should not be construed as being limited to the embodiments described below. This embodiment is for explaining the present invention in more detail to those having ordinary technical knowledge belonging to the technical field of the present invention. Therefore, the shape of each element shown in the drawings may be somewhat exaggerated for clearer emphasis.

[0048] On the other hand, although an ashing device will be described as an example below, the present invention can be applied to a semiconductor manufacturing device including a cleaning device and a vapor deposition device.

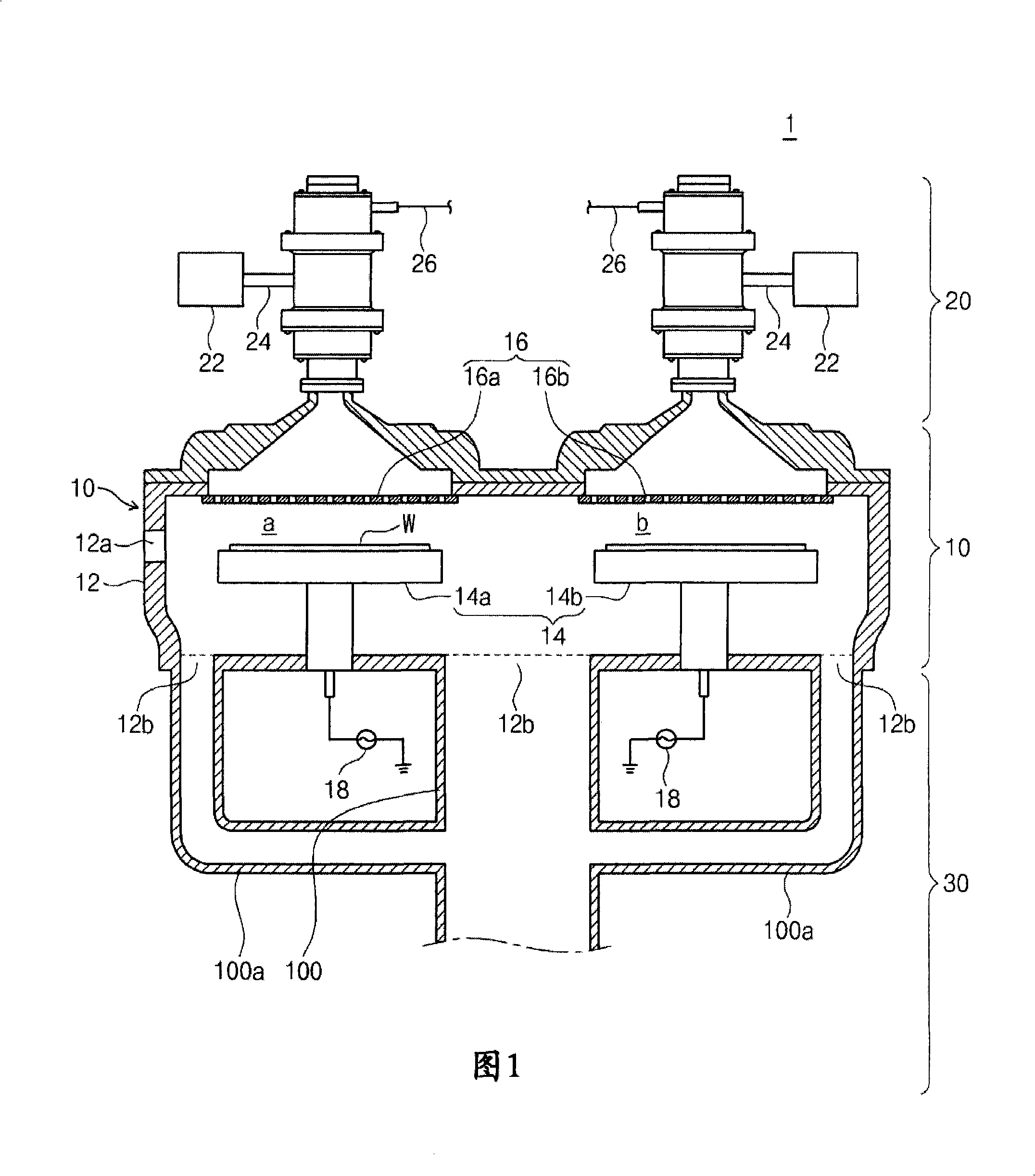

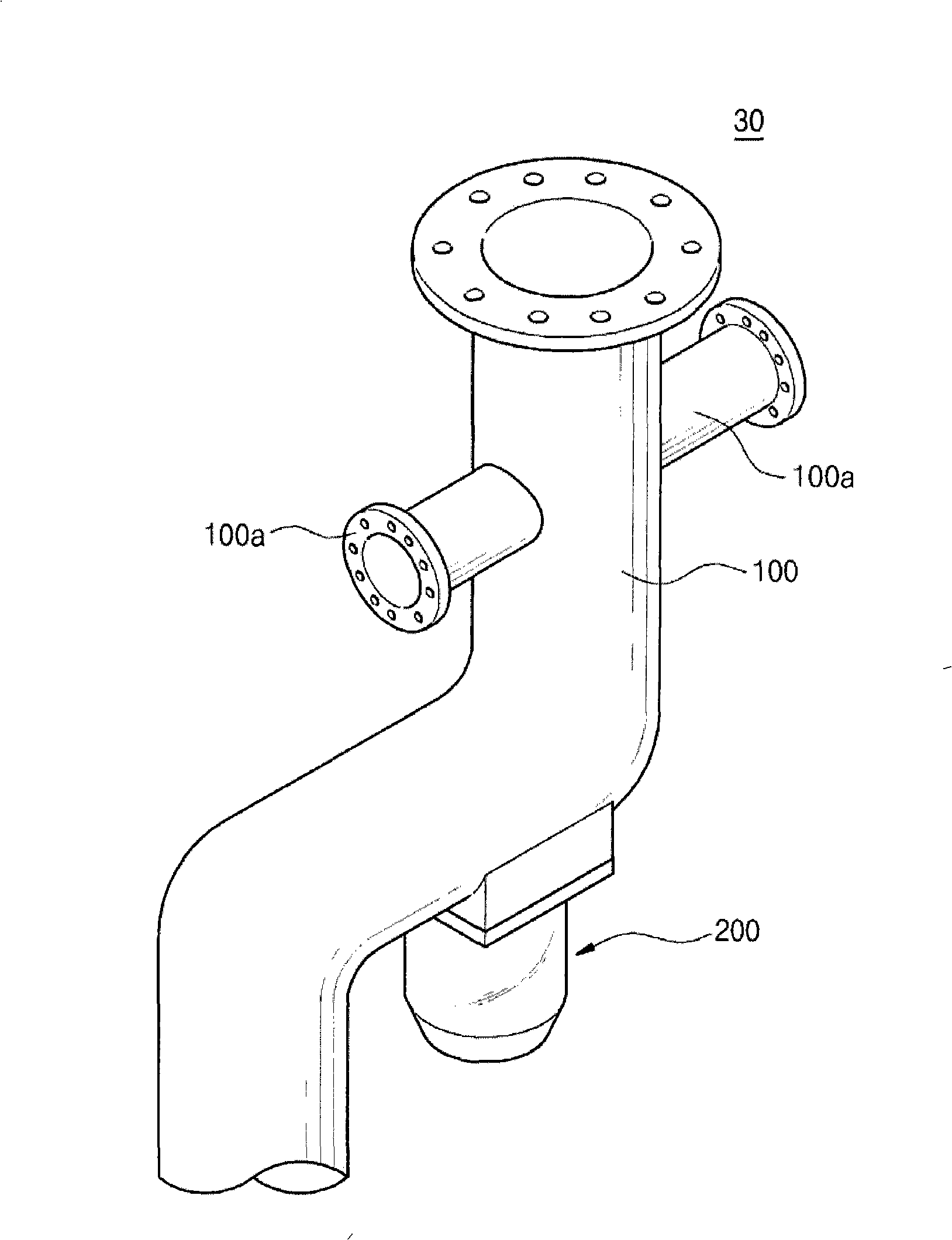

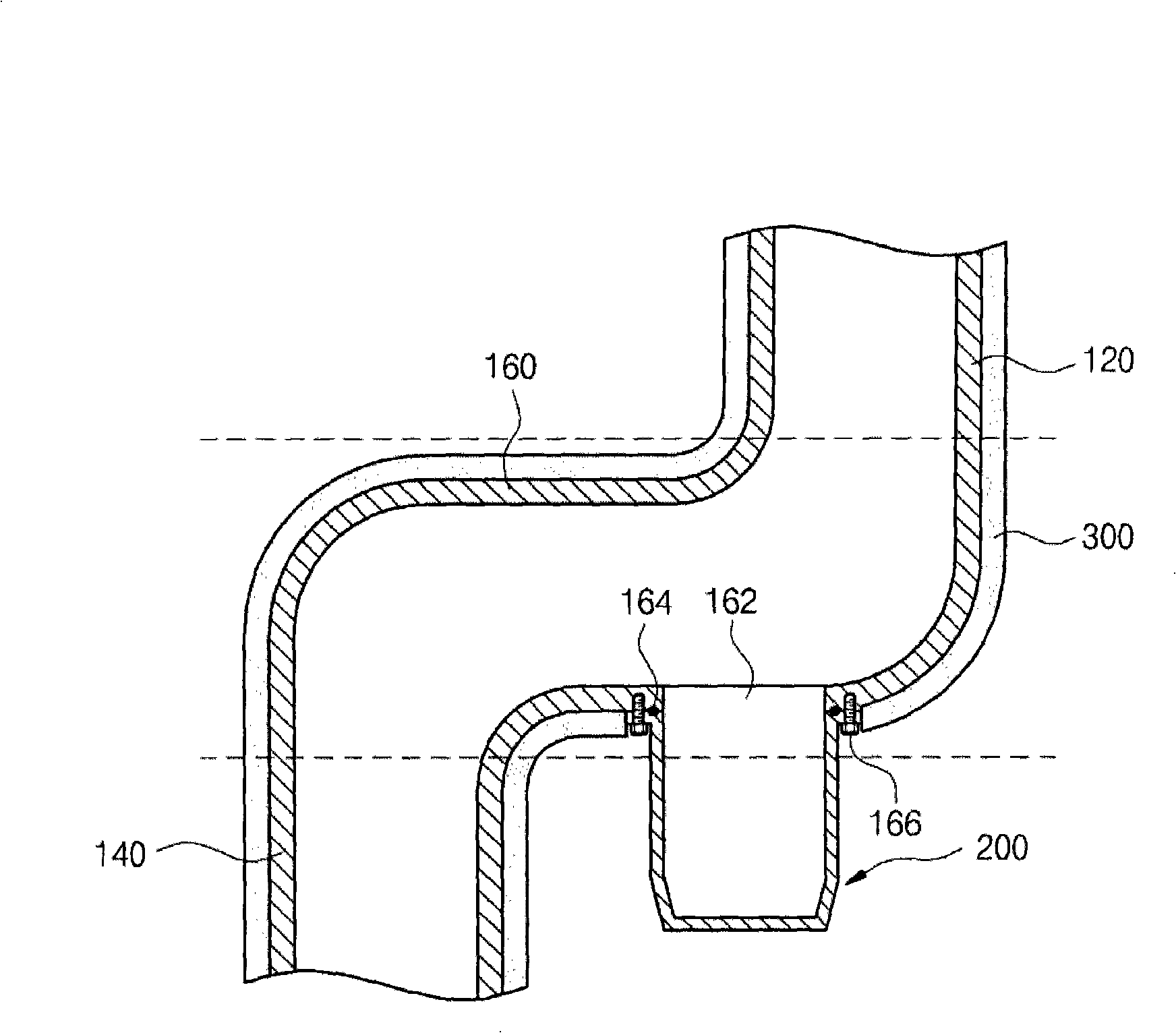

[0049] FIG. 1 is a cross-sectional view schematically showing the structure of a substrate processing apparatus 1 of the present invention.

[0050] As shown in FIG. 1 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com