UG environment parts list development system based on entity attribute

A technology of entity attributes and parts, applied in the field of parts list compilation system, it can solve problems such as time-consuming, error-prone, lack of integration, etc., to achieve optimal results, improve work efficiency, and save materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

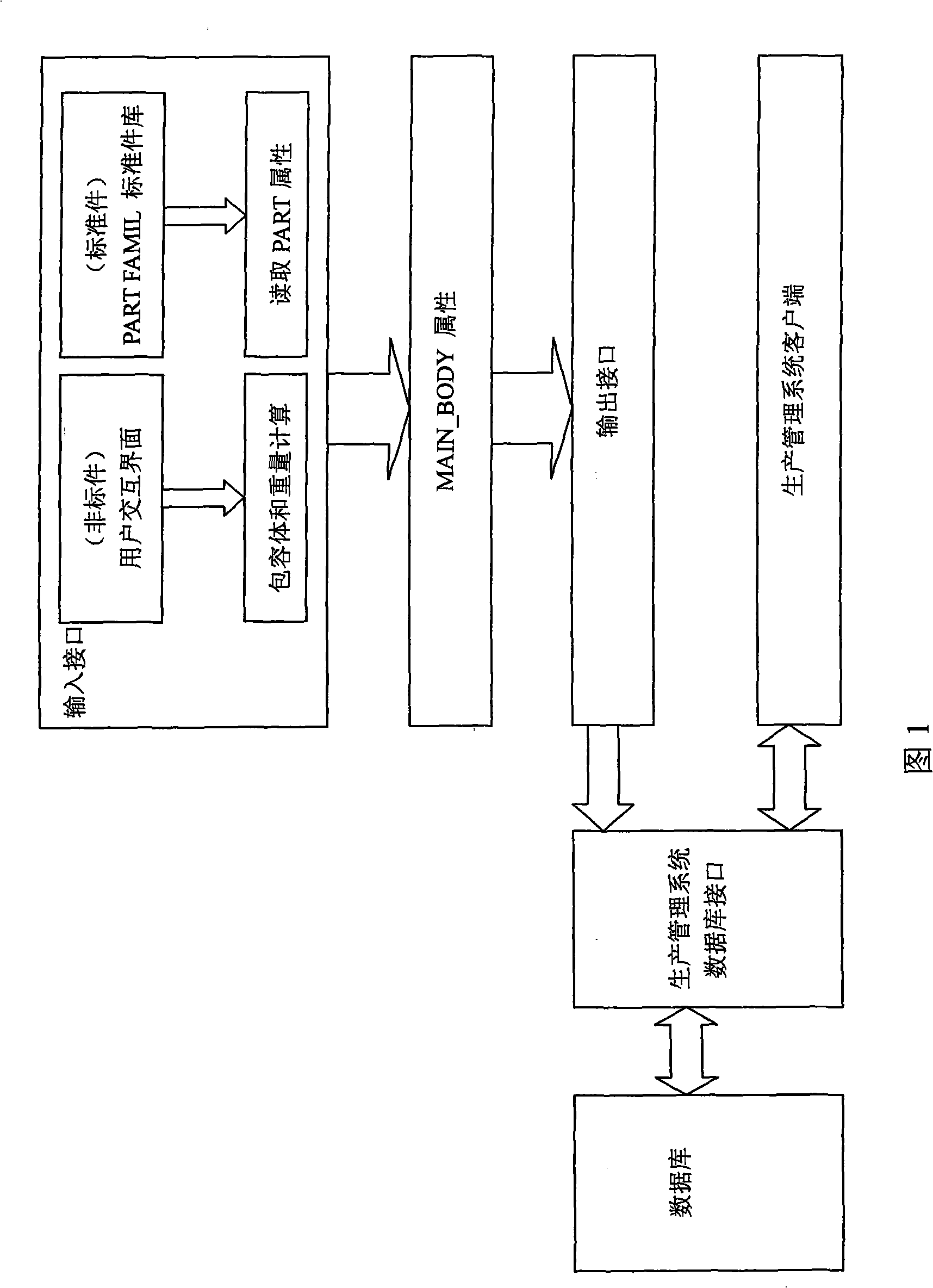

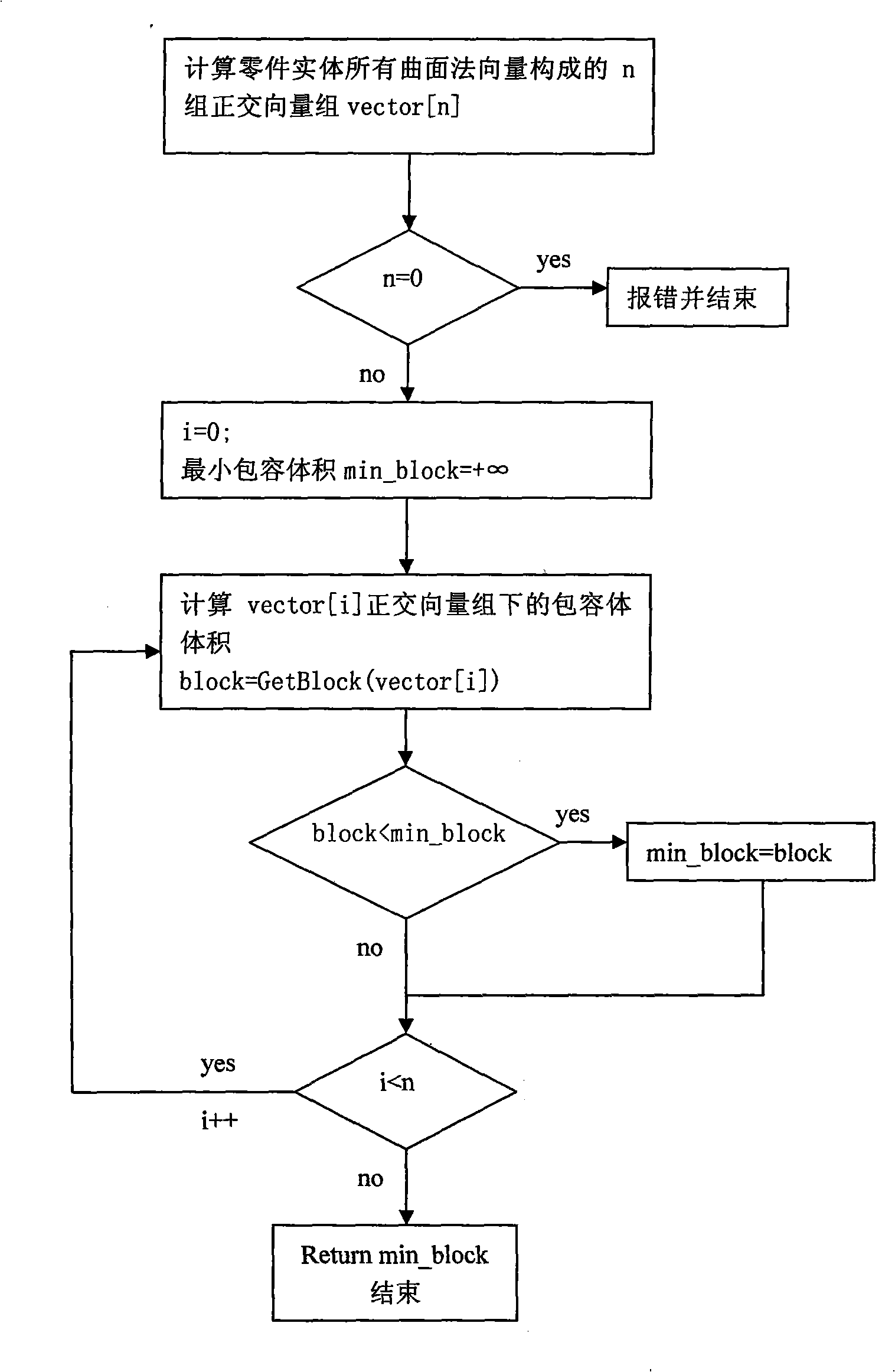

[0011] As shown in Figure 1, the input interface includes two functional modules, namely, the non-standard parts detail entry module and the standard part detail entry module. The detailed input information of non-standard parts includes blank size, weight and material; the detailed input information of standard parts includes standard number, specification code and index page. The non-standard parts detailed input module provides an interactive interface, and the designer can input the material of the non-standard parts, and the weight and blank size of the non-standard parts are related to the geometric characteristics of the entity, so they can be automatically calculated by the program (see attached figure 2 ). The standard part detail input module is based on the UG part family (part family) function. The standard part library is established through the part family to realize the parameterized drive modeling of the standard part, and the detailed information of the standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com