A loop concave output mirror laser resonance cavity

A laser resonator and output mirror technology, applied in the field of laser resonators, can solve the problems of small gain devices not suitable, high adjustment precision requirements, large loss, etc., and achieve low beam center power density, low manufacturing cost, and high performance reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

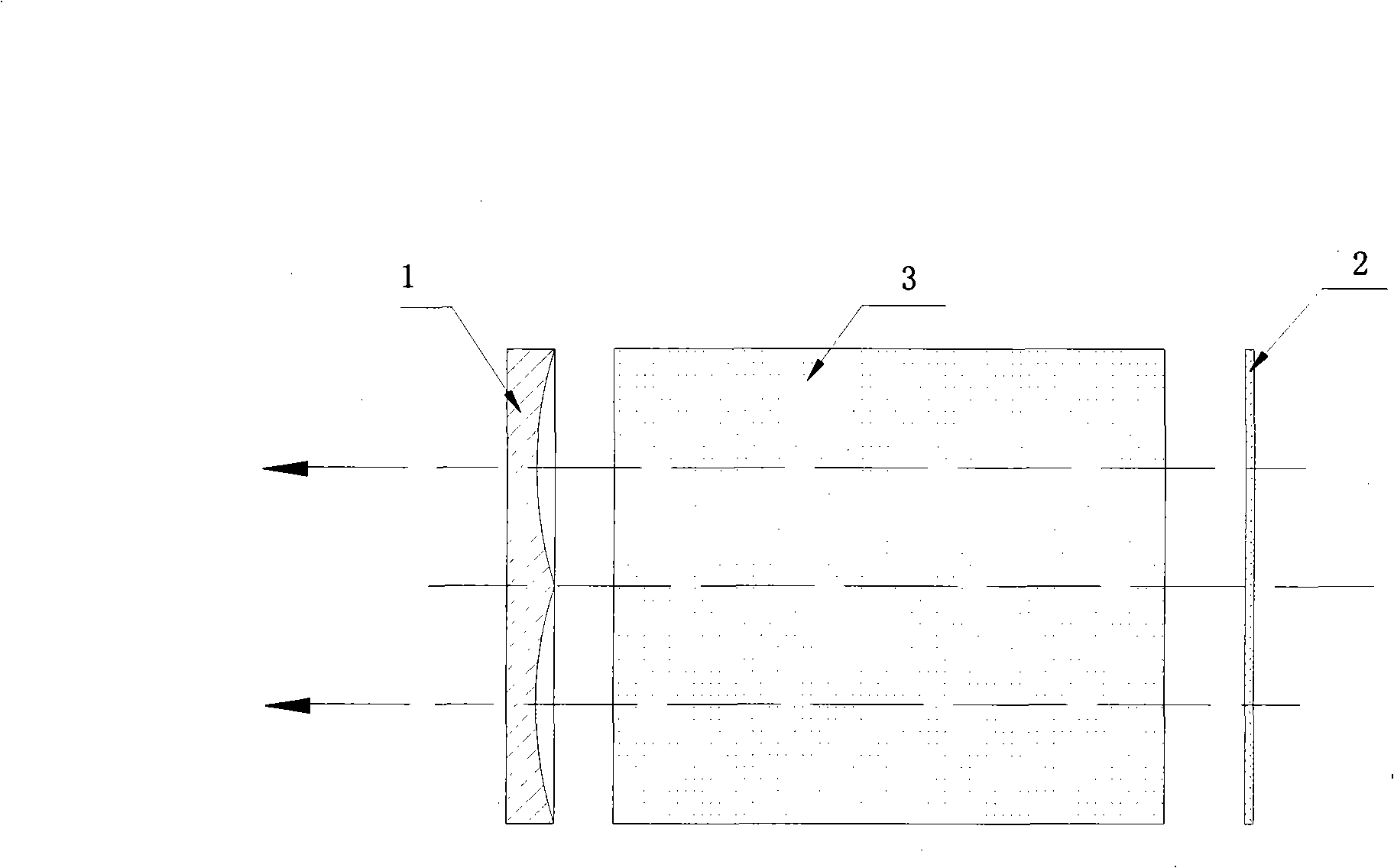

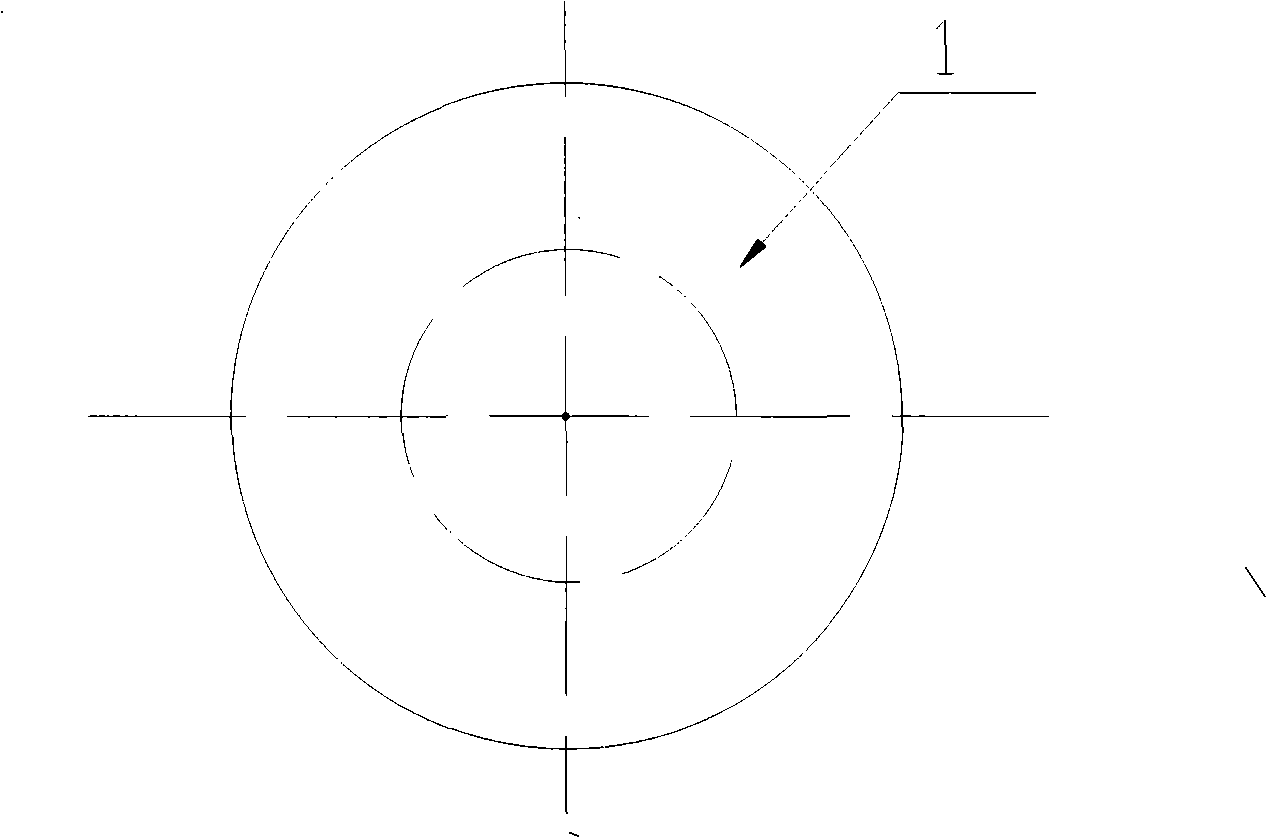

[0041] Depend on Figure 1 ~ Figure 2 As shown, a laser resonator with an annular concave output mirror includes a reflector 2, a laser working medium 3 and an output mirror 1. The output mirror 1 is an annular concave output mirror, and its working surface is composed of an annular arc-shaped concave surface.

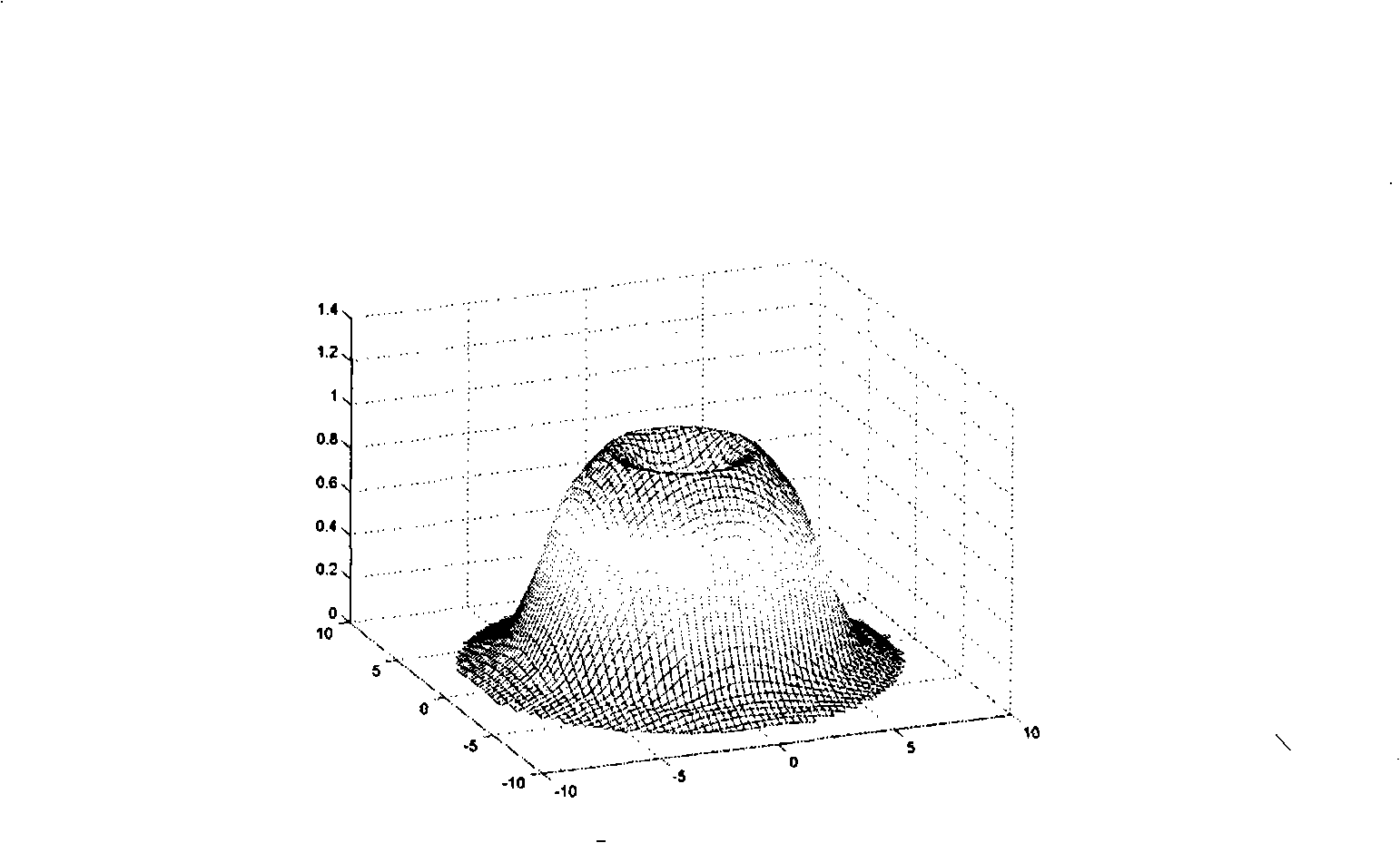

[0042] Analysis of the laser resonator in Example 1 shows that the output beam of the laser resonator of the annular concave output mirror is annular, and the power peak position is not at the center of the mirror, but on a circle with the center of the mirror as the center, which can reduce the output The temperature of the mirror, reflector and the center of the outer optical path lens reduces thermal deformation and improves beam stability. image 3 It is a schematic diagram of the output beam of Embodiment 1 of the present invention. Compared with the stable cavity, the laser resonator adopts the annular concave output mirror to ensure the quality of the output la...

Embodiment 2

[0044] Depend on Figure 4 ~ Figure 5 As shown, the output mirror 1 is an annular concave output mirror, and its working surface is composed of an annular arc-shaped concave surface and a central circular working surface. The above-mentioned central circular working surface can be a plane or a spherical surface.

[0045] Analysis of the laser resonator in Example 2 shows that the output beam of the laser resonator of the annular concave output mirror is annular, and the power peak position is not at the center of the mirror, but on a circle with the center of the mirror as the center, which can reduce the output The temperature of the mirror, reflector and the center of the outer optical path lens reduces thermal deformation and improves beam stability. Compared with the stable cavity, the laser resonator with annular concave output mirror can greatly increase the mode volume and greatly increase the laser output power under the condition that the quality of the output laser ...

Embodiment 3

[0047] Depend on Figure 6 ~ Figure 7 As shown, the output mirror 1 is an annular concave output mirror, its working surface includes an annular arc-shaped concave surface, the center of the mirror surface is a non-working surface or hollow, and the laser working medium 3 is an annular cylindrical working medium.

[0048]Analysis of the laser resonator of embodiment 3 shows that the laser resonator output beam of the annular concave output mirror is annular, and the power peak position is not at the center of the mirror, but on a circle with the center of the mirror as the center, which can reduce the The temperature of the output mirror, reflector and the center of the outer optical path lens reduces thermal deformation and improves beam stability. Compared with the stable cavity, the laser resonator using the annular concave output mirror can greatly increase the laser output power under the condition that the quality of the output laser beam is guaranteed and the divergence...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com