A method of manufacturing a mems capacitor microphone, a stack of foils comprising such a mems capacitor microphone, an electronic device comprising such a mems capacitor microphone and use of the ele

A technology of microsystems and electrodes, applied in the manufacture of microsystems, microsystems, foil stacks including microsystems, electronic devices including microsystems, and the use of electronic devices, capable of solving problems such as complex methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

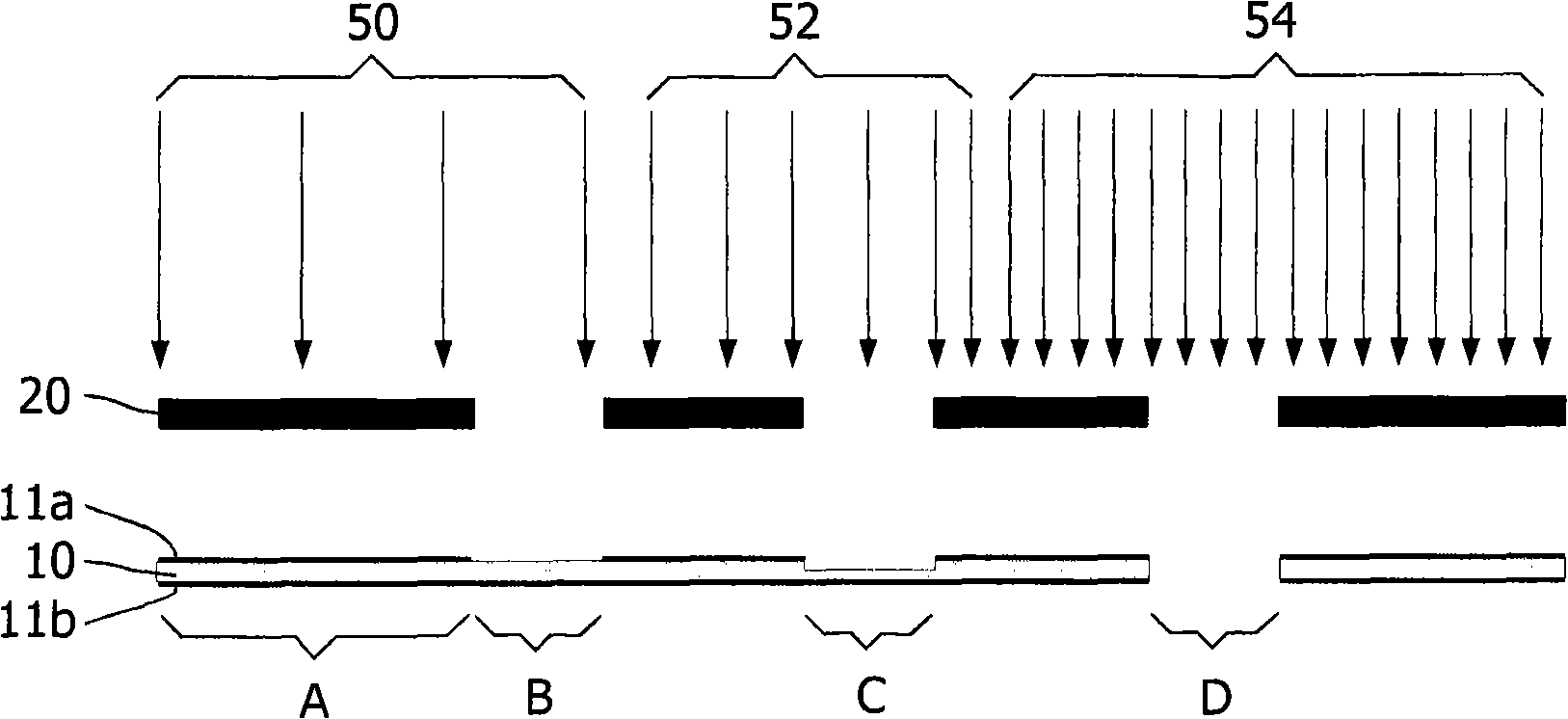

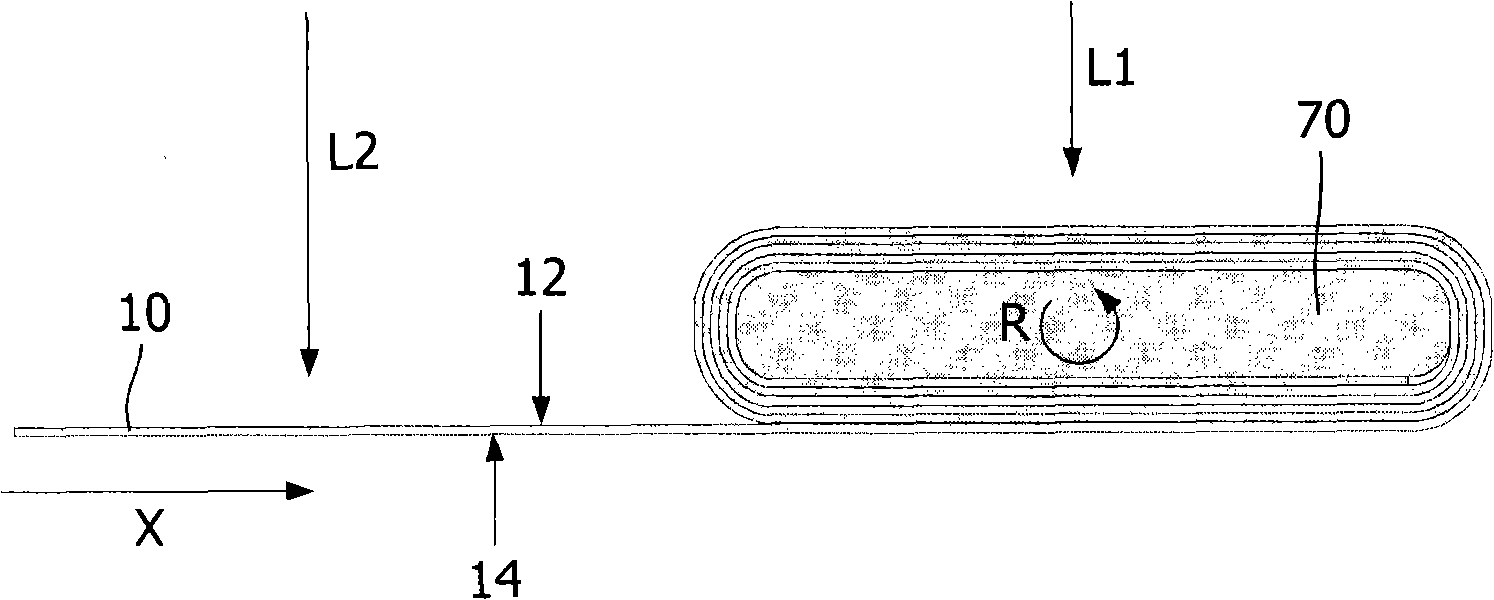

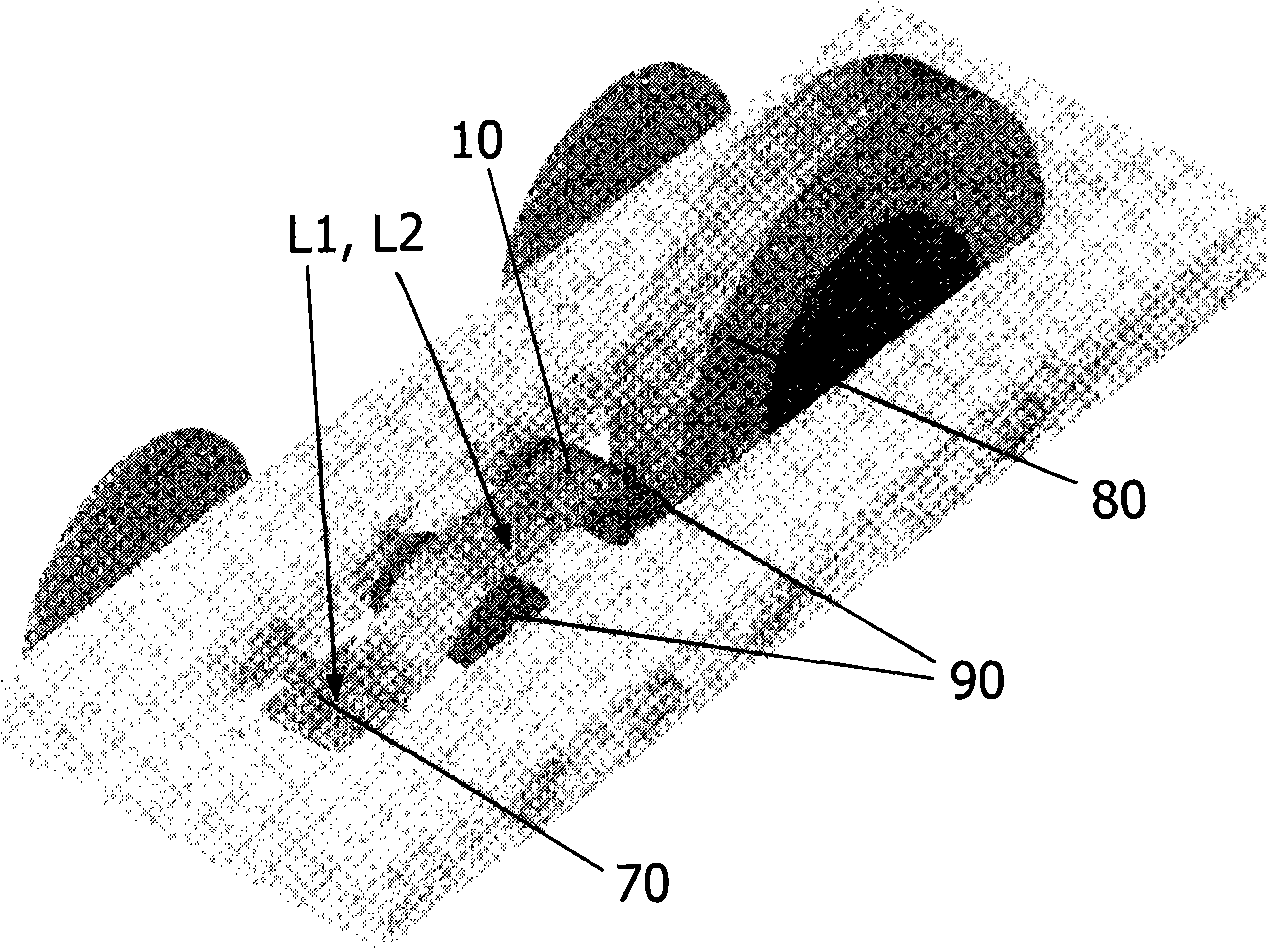

[0092] Hereinafter, a detailed description of the present invention will be given. As stated above, the present invention relates to methods of manufacturing microsystems as well as to such microsystems themselves. Many embodiments of the microsystem according to the invention are possible, and these embodiments are varied. However, all of these embodiments have one common factor in that they consist of joined-together laminates of pre-processed electrically insulating foils having, on at least one side thereof, conductive layer.

[0093] The method of manufacturing the microsystem includes the following sub-steps:

[0094] - applying a conductive layer on at least one side of the foil (so both sides are also possible, and in some cases even preferably on both sides);

[0095] - pretreating said foil;

[0096] - laminating said foils, thereby forming a microsystem;

[0097] - bonding (bonding, joining) said foil; and

[0098] - Separation of the microsystem from said foi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com