Method for preparing porous ceramic by electrostatic field and magnetic field co-inducing crystallization technique

A technology of porous ceramics and induced crystallization, which is applied in the field of material manufacturing and can solve problems such as no research results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

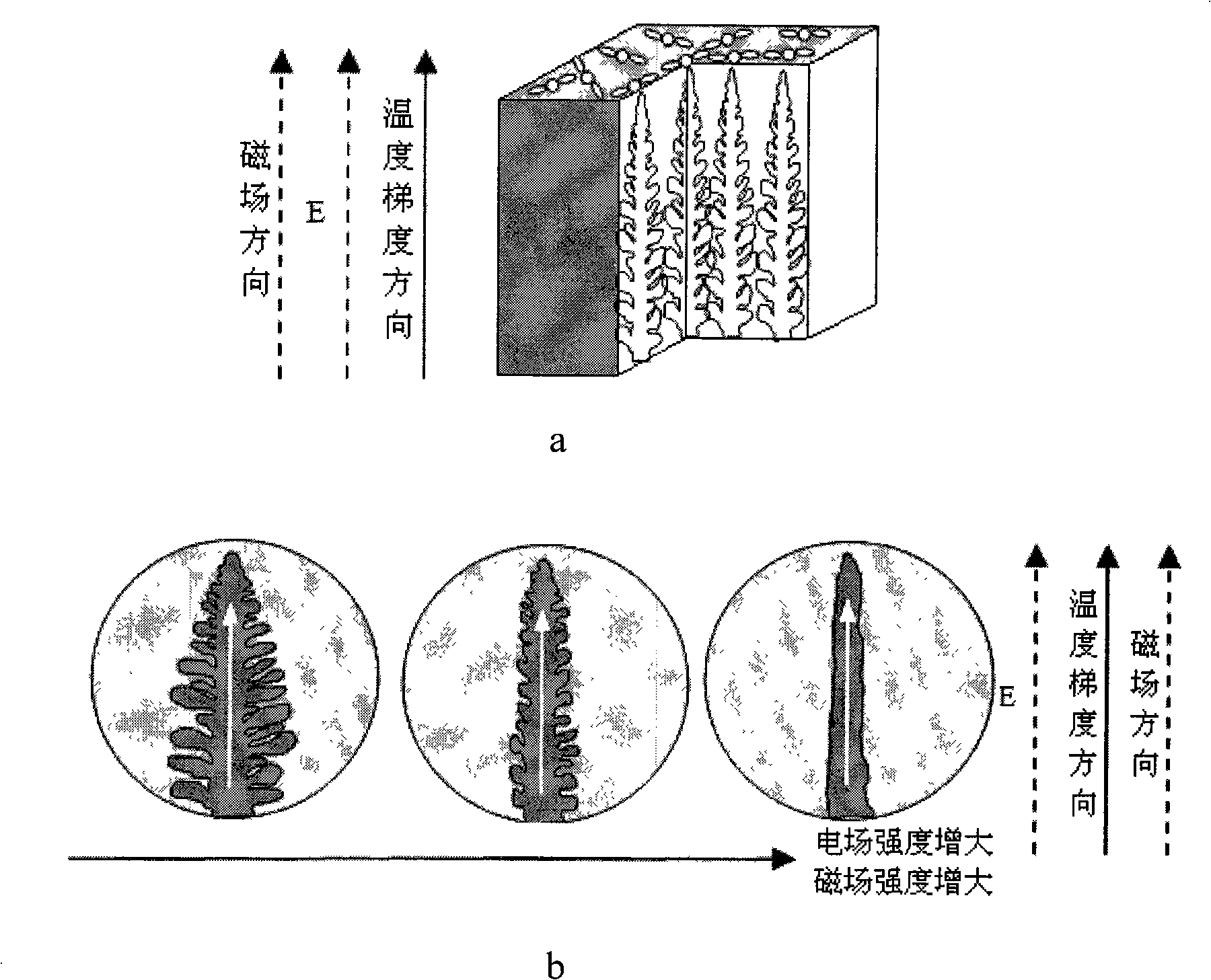

Method used

Image

Examples

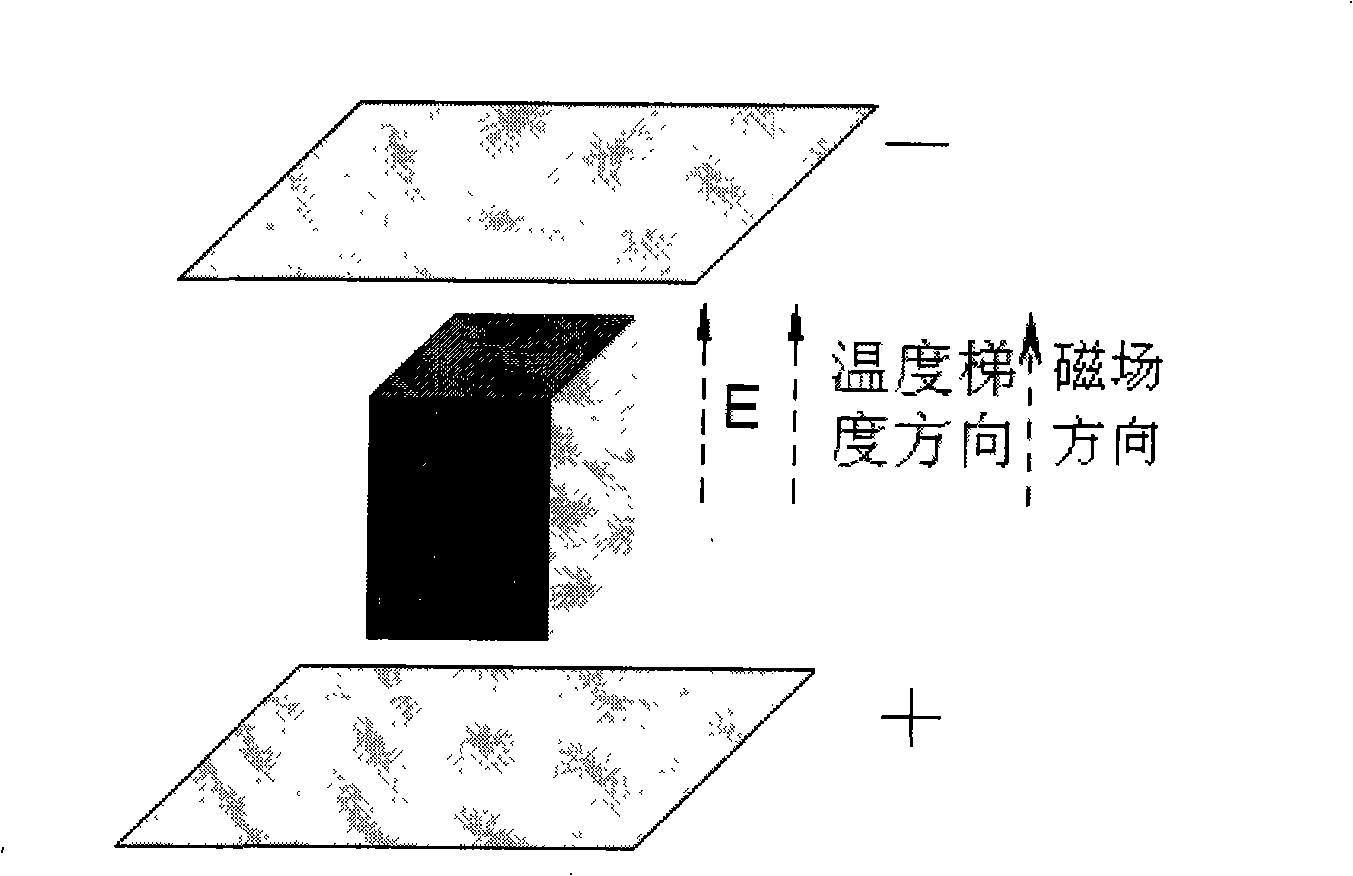

Embodiment 1

[0062] Take ZrO with a particle size of 0.1 μm to 50 μm 2 The powder is added in methanol and mixed to obtain ZrO with a solid phase volume content of 40%. 2 Ceramic slurry; ZrO 2 The ceramic slurry is injected into a mold with Cu on the bottom, phenolic foam on the side, and a cuboid inner cavity. The mold is frozen in an environment with a temperature gradient of 40°C / cm, an electric field strength of 3kV / m, and a magnetic field strength of 10GT. Perpendicular to the direction of the temperature gradient, the direction of the magnetic field is consistent with the direction of the temperature gradient. After the ceramic slurry was completely frozen, the sample was taken out of the mold and dried in a vacuum environment to obtain ZrO 2 The prefabricated body of porous ceramic material is sintered at 1350°C to obtain ZrO with a layered pore shape, a porosity of 60%, a pore diameter of 0.1mm×0.5mm, and a pore direction parallel to the direction of the electric field. 2 porous...

Embodiment 2

[0064] Take Al with a particle size of 0.1 μm to 50 μm 2 o 3 The powder is added to water and mixed to obtain an Al with a solid phase volume content of 30%. 2 o 3 Ceramic slurry; Al 2 o 3 The ceramic slurry is injected into a mold with Cu on the bottom, phenolic foam on the side, and a cuboid inner cavity. The mold is frozen in an environment with a temperature gradient of 20°C / m, an electric field strength of 10kV / m, and a magnetic field strength of 0.1GT. direction, the direction of the magnetic field is consistent with the direction of the temperature gradient. After the ceramic slurry was completely frozen, the sample was taken out of the mold and dried in a vacuum environment to obtain Al 2 o 3 Porous ceramic material prefabricated body, sintered at 1400 ° C, that is, Al with circular pore shape, average pore diameter of 100 μm, and random arrangement of pores can be obtained. 2 o 3 porous ceramic material. Micrographs of the cross-section of the porous ceramic ...

Embodiment 3

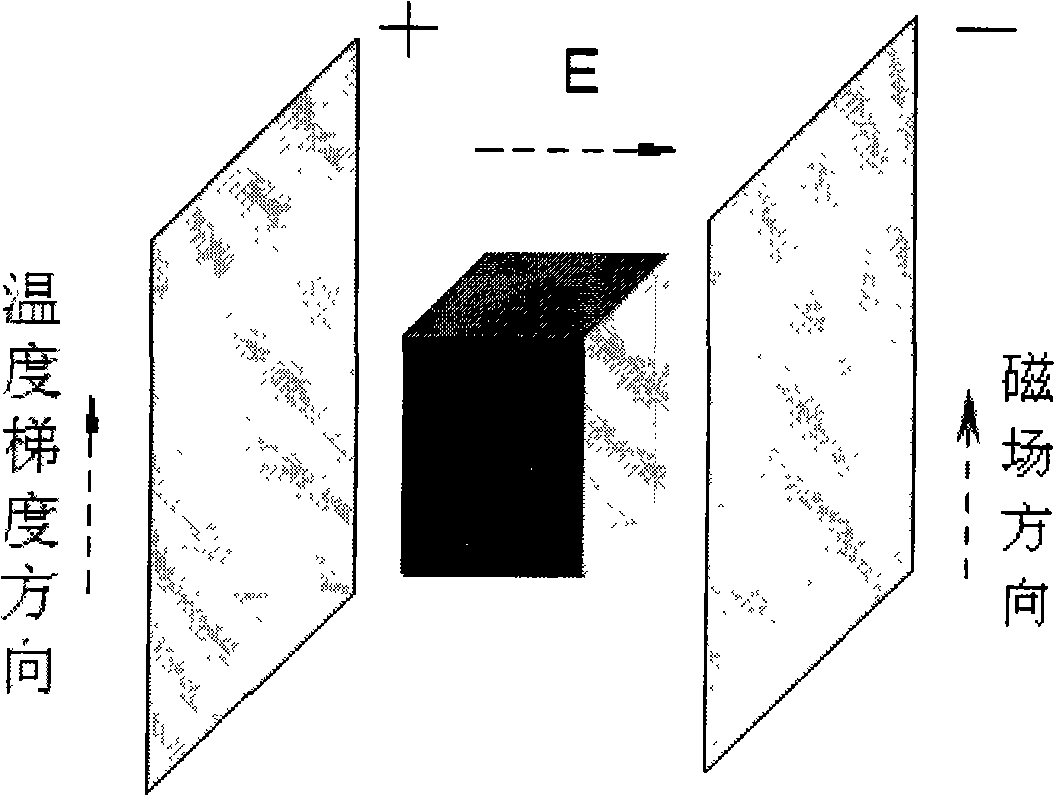

[0066] Add SiC powder with a particle size of 0.1 μm to 50 μm into acetone, and mix to obtain a SiC ceramic slurry with a solid phase volume content of 55%; inject the SiC ceramic slurry with Cu on the bottom, phenolic foam on the side, and a cylinder in the inner cavity In the mold, the mold is frozen in an environment with a temperature gradient of 60°C / cm, an electric field strength of 1kV / m, and a magnetic field strength of 30GT. The direction of the electric field points from the surroundings to the center of the sample and is perpendicular to the direction of the temperature gradient. The direction of the gradient is the same. After the ceramic slurry is completely frozen, take the sample out of the mold and dry it in a vacuum environment to obtain a SiC porous ceramic material prefabricated body, which is sintered at 1500°C to obtain an elliptical pore shape with a pore diameter of 0.1mm×0.4mm , SiC porous ceramic material with the direction of the holes pointing from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com